Carousel assembly system is used in a wide variety of industries, including automotive, electronics, food and beverage, and consumer goods. They are particularly well-suited for assembling products that have a high number of components or that require a high degree of precision.

Carousel assembly systems offer a number of advantages, including:

- Increased productivity: Carousel assembly systems can help to increase productivity by reducing the time required to assemble products. This is because the machines can perform multiple tasks simultaneously and can also be used to assemble products in parallel.

- Improved quality: Carousel assembly systems can help to improve the quality of assembled products by reducing the risk of errors. This is because the machines can be programmed to perform tasks consistently and accurately.

- Reduced costs: Carousel assembly systems can help to reduce the costs associated with assembly by eliminating the need for manual labor. This can free up workers to perform other tasks or to focus on quality control.

- Increased safety: Carousel assembly systems can help to improve safety by reducing the risk of accidents and injuries. This is because the machines can be programmed to perform tasks that would otherwise be hazardous for humans to perform.

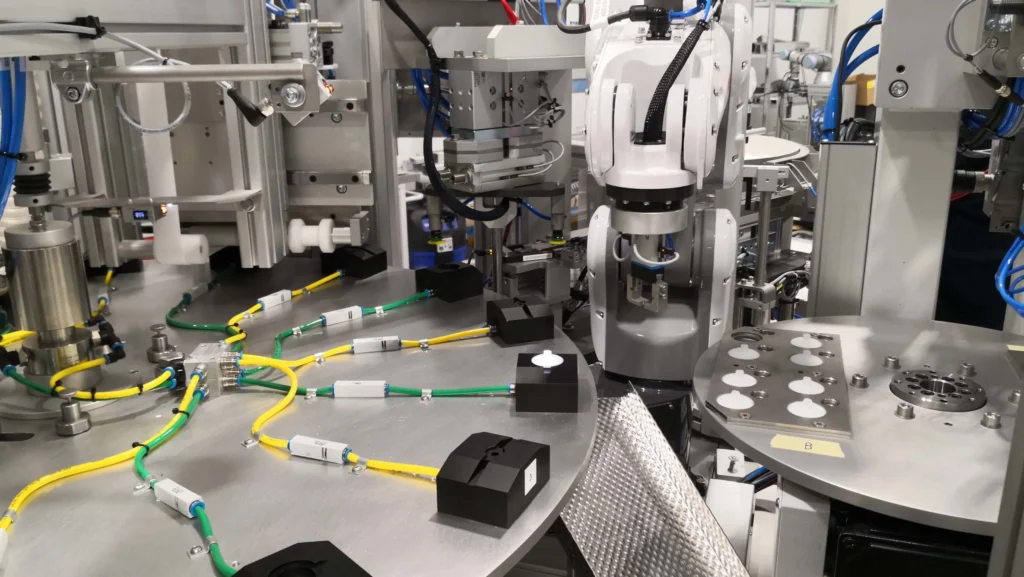

Carousel assembly systems can be automated to a high degree, using programmable logic controllers (PLCs), robots, and other automated equipment. This can help to further increase productivity, improve quality, and reduce costs.

Here are some examples of how carousel assembly systems are used in industry:

- In the automotive industry, carousel assembly systems are used to assemble car doors, dashboards, and other components.

- In the electronics industry, carousel assembly systems are used to assemble circuit boards and other electronic devices.

- In the food and beverage industry, carousel assembly systems are used to fill and seal containers, such as bottles, cans, and bags.

- In the consumer goods industry, carousel assembly systems are used to assemble toys, appliances, and other products.

Carousel assembly systems can be a valuable asset for businesses that need to assemble products quickly, accurately, and cost-effectively.

In addition to the advantages listed above, carousel assembly systems also offer the following benefits:

- Flexibility: Carousel assembly systems can be easily reconfigured to assemble different products. This makes them a good choice for businesses that need to produce a variety of products.

- Scalability: Carousel assembly systems can be scaled up or down to meet the production needs of the business. This makes them a good choice for businesses of all sizes.

- Ergonomics: Carousel assembly systems can help to improve the ergonomics of the workplace by reducing the need for workers to bend or reach. This can help to reduce the risk of injuries.

Overall, carousel assembly systems are a versatile and efficient way to assemble products. They can be used in a wide variety of industries and can be scaled to meet the needs of businesses of all sizes.

Carousel Assembly Systems In the Automotive Industry

In the automotive industry, carousel assembly systems are a type of manufacturing and assembly process that involves the use of a carousel or turntable to facilitate the efficient assembly of vehicle components. These systems are designed to improve workflow, enhance productivity, and reduce labor costs. Here are some key aspects of carousel assembly systems in the automotive industry:

- Component Organization: Carousel assembly systems are used to organize and present vehicle components, parts, and tools in an efficient manner. The carousel rotates to bring the required components to the assembly station, reducing the need for manual handling and transportation of parts.

- Improved Ergonomics: The rotating carousel allows operators to access components without the need for excessive bending, reaching, or walking. This ergonomic advantage reduces physical strain on assembly line workers, leading to improved worker comfort and reduced risk of workplace injuries.

- Assembly Line Efficiency: Carousel assembly systems are integrated into automotive assembly lines to optimize the sequence of assembly tasks. This reduces assembly time and ensures that components are readily available when needed, minimizing downtime.

- Customization: Carousel systems can be tailored to specific assembly needs. They can be configured with varying sizes and types of bins, trays, or tool holders to accommodate different components and tools used in the assembly process.

- Material Handling: In the automotive industry, heavy components and assemblies are common. Carousel systems can handle and present these materials efficiently, improving the flow of materials to the assembly line.

- Error Reduction: By bringing the right components to the assembly station in the correct order, carousel systems help reduce the likelihood of errors in assembly, leading to improved product quality and reliability.

- Workstation Flexibility: Carousel systems are adaptable to different types of assembly workstations. They can be used in various areas of the assembly line to suit the specific needs of the manufacturing process.

- Inventory Management: Carousel systems help manage inventory efficiently by providing a clear overview of the available components and their quantities. This aids in inventory control and reduces the risk of stockouts.

- Space Efficiency: Carousel systems are designed to make the most of available floor space. They are compact and do not require extensive storage areas for components, helping automotive manufacturers utilize space more effectively.

- Integration with Automation: In some cases, carousel assembly systems are integrated with robotic automation to further streamline the assembly process. This allows for increased precision and speed in the manufacturing of vehicles.

- Monitoring and Control: Some carousel systems include monitoring and control features, enabling real-time tracking of component usage, system status, and maintenance needs.

Carousel assembly systems are an integral part of modern automotive manufacturing, helping to enhance efficiency, reduce costs, and improve the overall quality of vehicles. They are particularly valuable in high-volume production environments where repetitive and standardized assembly tasks are common.

Carousel Assembly Systems In the Electronics Industry

In the electronics industry, carousel assembly systems are automated manufacturing solutions designed to streamline the assembly and production of electronic components and devices. These systems use a rotating carousel or turntable to present components and tools to operators at assembly workstations, enhancing efficiency and productivity. Here are some key aspects of carousel assembly systems in the electronics industry:

- Component Organization: Carousel assembly systems are used to organize electronic components, parts, and tools in a systematic and easily accessible manner. The carousel rotates to bring the required components and tools to the assembly station, reducing the time and effort required for manual handling and searching for parts.

- Efficient Workflow: These systems are designed to optimize the workflow in electronics assembly. By bringing components to the assembly point when needed, they reduce idle time and contribute to a smoother production process.

- Customization: Carousel systems can be customized to accommodate the specific needs of electronic assembly. They can be configured with various sizes and types of bins, trays, tool holders, and component racks to accommodate different types of electronic components, such as resistors, capacitors, semiconductors, connectors, and more.

- Error Reduction: By presenting the right components and tools to assembly operators in the correct order, carousel assembly systems help minimize assembly errors. This is especially critical in the electronics industry, where precision is essential to product functionality and reliability.

- Ergonomics: The rotating carousel minimizes the need for operators to reach or move extensively, reducing physical strain and enhancing operator comfort. This ergonomic advantage is important for maintaining a healthy and productive work environment.

- Integration with Automation: In electronics manufacturing, carousel assembly systems can be integrated with robotic automation to further enhance precision and speed in the assembly process. Robotic arms can pick and place components from the carousel, increasing the level of automation.

- Inventory Management: Carousel systems help manage electronic component inventory efficiently by providing a clear overview of the available components and their quantities. This aids in inventory control, reduces the risk of stockouts, and ensures that components are used in a first-in, first-out (FIFO) manner.

- Space Efficiency: Carousel systems are designed to maximize the efficient use of available floor space in electronics assembly facilities. They have a relatively small footprint and do not require extensive storage areas for components.

- Quality Control: The presentation of components in a controlled manner facilitates the implementation of quality control measures, such as visual inspections and testing, at assembly workstations.

- Monitoring and Control: Some carousel assembly systems feature monitoring and control capabilities, allowing manufacturers to track component usage, system status, and maintenance needs in real time.

Carousel assembly systems play a crucial role in the electronics industry, where precision, efficiency, and productivity are essential for meeting the demands of high-tech electronic device manufacturing. These systems contribute to the overall quality and consistency of electronic products while optimizing the assembly process.

Carousel Assembly Systems In the Food and Beverage Industry

In the food and beverage industry, carousel assembly systems are less common than in manufacturing industries like electronics and automotive. However, they can still be found in certain applications within the food and beverage sector, particularly in food processing and packaging. Here are some key aspects of carousel assembly systems in the food and beverage industry:

- Packaging Assembly: Carousel assembly systems are used in the food and beverage industry for packaging and labeling applications. They are particularly useful for sorting and assembling food items into packaging containers, such as bottles, jars, or trays.

- Labeling: These systems can be integrated with labeling machines to automate the application of product labels, nutrition facts, barcodes, and other packaging information on food and beverage containers.

- Bottle Filling: In beverage production, carousel assembly systems are often used for bottle filling and capping processes. They can be customized to accommodate various bottle sizes and cap types.

- Conveyor Integration: Carousel systems can be integrated with conveyor belts, allowing a continuous flow of food and beverage products to the assembly and packaging stations.

- Customization: The design of carousel systems in the food and beverage industry can be customized to suit the specific needs of the products being processed. They can be configured with various container sizes, bottle types, and labeling requirements.

- Quality Control: Carousel assembly systems can be equipped with quality control features such as vision inspection systems to check for defects, fill levels, and labeling accuracy.

- Speed and Efficiency: These systems are designed to improve production efficiency by presenting containers to operators at a controlled rate, reducing the time and effort required for manual handling and assembly.

- Ergonomics: The design of carousel systems can be optimized for ergonomics, ensuring that operators can work comfortably and efficiently while assembling and packaging food and beverage products.

- Inventory Management: These systems can help manage inventory by providing a clear overview of the available food and beverage products and their quantities. This aids in inventory control and reduces the risk of stockouts.

- Hygiene and Food Safety: In the food industry, hygiene and food safety are of utmost importance. Carousel assembly systems are designed with easy-to-clean materials and surfaces, and they often include features that prevent product contamination.

- Regulatory Compliance: Food and beverage assembly systems must meet industry-specific standards and regulatory requirements to ensure food safety and compliance with labeling regulations.

- Custom Labels and Branding: In the food industry, labels and packaging often include custom branding and design to make the product stand out on store shelves.

While carousel assembly systems are not as common in the food and beverage industry as in some other sectors, they are utilized in specific applications that require high efficiency and precision, such as bottle filling and labeling. These systems play a role in improving productivity, reducing errors, and ensuring that food and beverage products meet quality and safety standards.

Carousel Assembly Systems In the Consumer Goods Industry

In the consumer goods industry, carousel assembly systems are used to streamline the manufacturing and assembly of various consumer products, including items such as household appliances, small electronics, furniture, and other consumer goods. Carousel assembly systems offer several advantages, including improved efficiency, ergonomics, and quality control. Here are some key aspects of carousel assembly systems in the consumer goods industry:

- Component Organization: Carousel assembly systems help organize and present components, parts, and tools to operators in an efficient and easily accessible manner. The rotating carousel brings the required components and tools to the assembly station, reducing the need for manual handling and transportation of parts.

- Workflow Optimization: These systems are designed to optimize workflow in the assembly process. By presenting components to the assembly point as needed, they reduce downtime and contribute to a more efficient production process.

- Customization: Carousel systems can be tailored to accommodate the specific needs of consumer goods assembly. They can be configured with different sizes and types of bins, trays, tool holders, and component racks to suit the various components used in assembly.

- Error Reduction: By bringing the right components and tools to assembly operators in the correct order, carousel assembly systems help minimize assembly errors, leading to improved product quality and reliability.

- Ergonomics: The rotating carousel minimizes the need for operators to reach or move excessively, reducing physical strain and enhancing operator comfort. This ergonomic advantage is important for maintaining a healthy and productive work environment.

- Integration with Automation: In the consumer goods industry, carousel assembly systems can be integrated with robotic automation to further enhance precision and speed in the assembly process. Robotic arms can pick and place components from the carousel, increasing the level of automation.

- Inventory Management: Carousel systems help manage component inventory efficiently by providing a clear overview of the available components and their quantities. This aids in inventory control and reduces the risk of stockouts.

- Space Efficiency: Carousel systems are designed to make the most of available floor space in consumer goods assembly facilities. They have a relatively small footprint and do not require extensive storage areas for components.

- Quality Control: The presentation of components in a controlled manner facilitates the implementation of quality control measures, such as visual inspections and testing, at assembly workstations.

- Packaging and Labeling: Some consumer goods, such as electronics and appliances, require final packaging and labeling. Carousel systems can be integrated into packaging lines to assist with these processes.

- Monitoring and Control: Some carousel assembly systems have monitoring and control capabilities, allowing manufacturers to track component usage, system status, and maintenance needs in real time.

Carousel assembly systems are valuable in the consumer goods industry, where efficiency and precision are essential for meeting production demands and ensuring product quality. These systems contribute to overall productivity and product consistency while optimizing the assembly process.