An industrial automated assembly line is a system that uses automation to assemble products. Automated assembly lines are used in a wide range of industries, including automotive, electronics, food and beverage, and pharmaceuticals.

Human-Machine Interface (HMI) and Supervisory Control and Data Acquisition (SCADA) systems play crucial roles in optimizing the operation and monitoring of automated assembly processes. Acting as interactive portals, HMIs provide a user-friendly interface for operators to oversee and control assembly systems, ensuring a seamless interaction between human operators and advanced automation technologies.

The utilization of exoskeletons introduces a safety element to automated assembly, offering support and augmentation to human capabilities in physically demanding industrial environments. This integration fosters a harmonious coexistence between human expertise and robotic precision, promoting both safety and efficiency in the industrial workspace.

Collaborative Robots (Cobots) exemplify the evolving nature of human-robot collaboration. Working alongside their human counterparts, Cobots enhance efficiency and safety in shared workspaces. This collaborative frontier not only transforms the dynamics of assembly tasks but also marks a paradigm shift in industrial interactions.

As the industry delves into the era of Industry 4.0, the integration of the Industrial Internet of Things (IIoT) continues to shape the landscape. Connected devices and data-driven decision-making ensure intelligent manufacturing, where automated assembly adapts and responds to real-time insights, optimizing processes with unprecedented efficiency.

This convergence of technologies underscores the multifaceted nature of automated assembly, where precision, collaboration, safety, and connectivity coalesce to redefine the future of manufacturing and production.

Industrial Automated Assembly Line

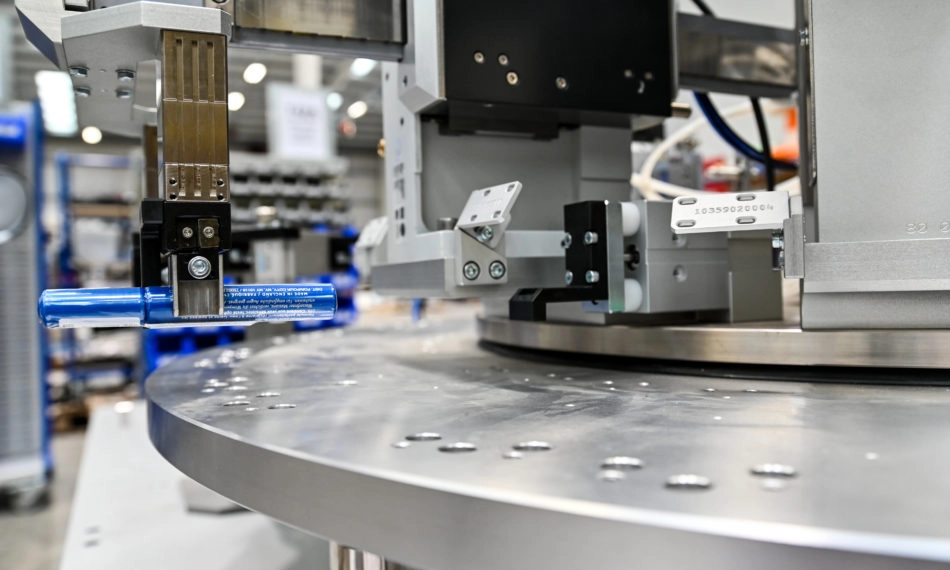

Automated assembly stands as a cornerstone in modern industrial processes, where robotics and precision play pivotal roles. Robotic arms, guided by sophisticated automation systems, intricately maneuver and assemble components along assembly lines. The synergy of conveyor systems and pick-and-place mechanisms ensures a seamless flow, optimizing efficiency in the intricate dance of assembly automation.

End-effectors, the specialized tools attached to robotic arms, contribute to the precision assembly of components. This orchestrated dance of automation extends to the realm of collaborative robots (Cobots), which work harmoniously alongside human counterparts, enhancing the flexibility and adaptability of assembly processes.

In the broader context of industrial automation, flexible automation takes center stage, allowing assembly systems to adapt to varying tasks and configurations. Automated guided vehicles (AGVs) facilitate the smooth transport of components, contributing to the continuous flow within the assembly line. Vision systems and smart manufacturing principles further augment automated assembly, ensuring accuracy and real-time adaptability.

As we delve into the era of Industry 4.0, the integration of technologies such as machine vision and collaborative assembly reshapes the landscape, driving efficiencies and setting new standards for automated assembly line efficiency.

Automated assembly lines typically consist of a series of workstations, each of which performs a specific task in the assembly process. For example, one workstation might pick and place components, while another workstation might fasten components together. The workstations are linked together by a conveyor belt, which moves the products from one workstation to the next.

Automated assembly lines are typically controlled by a computer system, which monitors the progress of the products through the assembly line and ensures that each task is completed correctly. The computer system can also be used to collect data on the assembly process, which can be used to improve efficiency and quality.

Automated assembly lines offer a number of benefits, including:

- Increased productivity: Automated assembly lines can help to increase productivity by automating repetitive and time-consuming tasks.

- Improved quality: Automated assembly lines can help to improve quality by reducing the risk of human error.

- Reduced costs: Automated assembly lines can help to reduce costs by reducing labor costs and by improving efficiency.

- Improved safety: Automated assembly lines can help to improve safety by reducing the risk of workplace accidents.

Automated assembly lines are a key part of modern manufacturing, and they are playing an increasingly important role in helping businesses to improve their efficiency, productivity, quality, and safety.

Here are some examples of how industrial automated assembly lines are being used today:

- Automotive: In the automotive industry, automated assembly lines are used to assemble cars, trucks, and other vehicles.

- Electronics: In the electronics industry, automated assembly lines are used to assemble circuit boards, smartphones, computers, and other electronic devices.

- Food and beverage: In the food and beverage industry, automated assembly lines are used to package food and beverages, and to palletize products for shipping.

- Pharmaceuticals: In the pharmaceutical industry, automated assembly lines are used to package drugs and other pharmaceutical products.

Industrial automated assembly lines are a rapidly growing field, and there are many new and innovative applications for it. As automation continues to develop, we can expect to see even more businesses using industrial automated assembly lines to improve their operations.

Industrial Automated Assembly Line

The evolution of automated assembly is marked by the seamless integration of robotics, where precision and efficiency converge on the assembly line. Industrial automation, propelled by robotics integration, transforms assembly processes into intricate choreography. The symphony of robotic arms, coupled with conveyor systems, orchestrates a dance of precision that defines the modern landscape of assembly automation.

In this precision dance, end-effectors emerge as the unsung heroes, delicately manipulating components with accuracy. Automated guided vehicles (AGVs) contribute to the fluidity of the process, navigating autonomously to transport materials seamlessly through the assembly line. Collaborative robots (Cobots) join the ensemble, working in tandem with human operators to enhance adaptability and flexibility in assembly tasks.

Flexible automation takes center stage, allowing assembly systems to seamlessly adapt to changing requirements. High-speed assembly becomes a hallmark, with robotics and automation ensuring rapid and precise assembly of components. Vision systems, an integral part of this automation symphony, provide real-time insights, ensuring quality control and accuracy in the assembly process.

The advent of Industry 4.0 amplifies these dynamics, ushering in smart manufacturing principles. Automation cells, equipped with robotic grippers, automated inspection, and adaptive assembly capabilities, embody the cutting edge of assembly automation. This transformative era is characterized by the fusion of advanced technologies, reshaping the landscape of automated assembly into a realm of unprecedented precision and efficiency.

Industrial assembly automation is the use of robots and other automated technologies to assemble products. It is a rapidly growing field, as businesses are increasingly looking to automation to improve efficiency, productivity, and quality.

There are many different types of industrial assembly automation systems, but some of the most common include:

- Robotic assembly systems: Robotic assembly systems use robots to perform assembly tasks, such as picking and placing parts, fastening components, and applying adhesives.

- Conveyor belt assembly systems: Conveyor belt assembly systems use conveyor belts to move products through different assembly stations, where they are assembled by robots or human workers.

- Automated assembly machines: Automated assembly machines are designed to perform specific assembly tasks, such as assembling circuit boards or assembling engines.

Industrial assembly automation systems can be used to assemble a wide range of products, including:

- Electronics: Circuit boards, smartphones, computers, and other electronic devices.

- Automotive: Cars, trucks, and other vehicles.

- Aerospace: Airplanes, spacecraft, and other aerospace components.

- Medical devices: Pacemakers, stents, and other medical devices.

- Consumer goods: Appliances, toys, and other consumer goods.

Industrial assembly automation offers a number of benefits, including:

- Increased productivity: Industrial assembly automation can help to increase productivity by automating repetitive and time-consuming tasks.

- Improved quality: Industrial assembly automation can help to improve quality by reducing the risk of human error.

- Reduced costs: Industrial assembly automation can help to reduce costs by reducing labor costs and by improving efficiency.

- Improved safety: Industrial assembly automation can help to improve safety by reducing the risk of workplace accidents.

Industrial assembly automation is a key part of modern manufacturing, and it is playing an increasingly important role in helping businesses to improve their efficiency, productivity, quality, and safety.

Here are some examples of how industrial assembly automation is being used today:

- Electronics: In the electronics industry, industrial assembly automation is used to assemble circuit boards, smartphones, computers, and other electronic devices.

- Automotive: In the automotive industry, industrial assembly automation is used to assemble cars, trucks, and other vehicles.

- Aerospace: In the aerospace industry, industrial assembly automation is used to assemble airplanes, spacecraft, and other aerospace components.

- Medical devices: In the medical device industry, industrial assembly automation is used to assemble pacemakers, stents, and other medical devices.

- Consumer goods: In the consumer goods industry, industrial assembly automation is used to assemble appliances, toys, and other consumer goods.

Industrial assembly automation is a rapidly growing field, and there are many new and innovative applications for it. As automation continues to develop, we can expect to see even more businesses using industrial assembly automation to improve their operations.

Industrial Automated Assembly Line Applications

Within the realm of automated assembly, the precision offered by robotic arms is complemented by the integration of conveyor systems, forming an intricate dance that defines the efficiency of assembly lines. Automated guided vehicles (AGVs) contribute to this orchestrated performance, seamlessly transporting components across the assembly line with autonomy and precision.

Collaborative robots (Cobots) join this choreography, working in tandem with human operators to enhance adaptability and flexibility in assembly tasks. The concept of flexible automation takes center stage, allowing assembly systems to seamlessly adapt to varying tasks and configurations, ensuring a dynamic response to changing production needs.

High-speed assembly emerges as a hallmark of modern automated processes, where robotics and automation systems work in concert to achieve rapid and precise assembly of components. Vision systems play a crucial role in this process, providing real-time insights for quality control and accuracy, ensuring that each assembly meets the desired standards.

As the industry advances into the era of Industry 4.0, the principles of smart manufacturing come to the forefront. Automation cells equipped with robotic grippers, automated inspection systems, and adaptive assembly capabilities exemplify the cutting edge of assembly automation. This transformative era is characterized by the integration of advanced technologies, reshaping the landscape of automated assembly into a realm of unprecedented precision and efficiency.

Industrial automated assembly lines are used in a wide variety of industries to assemble products of all shapes and sizes. Here are some specific examples:

- Automotive: Automated assembly lines are widely used in the automotive industry to assemble cars, trucks, and other vehicles. Robots perform a variety of tasks on automotive assembly lines, such as welding body panels, painting car bodies, and installing engines and other components.

- Electronics: Automated assembly lines are also widely used in the electronics industry to assemble electronic devices such as smartphones, computers, and televisions. Robots perform a variety of tasks on electronics assembly lines, such as placing components on circuit boards, soldering components together, and testing finished products.

- Food and beverage: Automated assembly lines are also used in the food and beverage industry to package food and beverages. Robots perform a variety of tasks on food and beverage assembly lines, such as picking and placing food items in containers, filling containers with liquids, and sealing containers.

- Pharmaceuticals: Automated assembly lines are also used in the pharmaceutical industry to package pharmaceuticals. Robots perform a variety of tasks on pharmaceutical assembly lines, such as picking and placing pharmaceutical products in containers, filling containers with pharmaceutical products, and sealing containers.

- Consumer goods: Automated assembly lines are also used in the consumer goods industry to assemble a wide variety of products, such as personal care products, household goods, and toys. Robots perform a variety of tasks on consumer goods assembly lines, such as picking and placing parts, assembling products, and testing finished products.

Automated assembly lines offer a number of benefits over manual assembly lines, including:

- Increased productivity: Automated assembly lines can run faster and more efficiently than manual assembly lines, resulting in increased productivity.

- Improved quality: Automated assembly lines can help to improve product quality by reducing the risk of human error.

- Reduced costs: Automated assembly lines can help to reduce costs by reducing the need for manual labor and improving efficiency.

- Increased safety: Automated assembly lines can help to improve safety by reducing the need for workers to interact with dangerous machinery.

- Reduced environmental impact: Automated assembly lines can help to reduce environmental impact by reducing waste and energy consumption.

Overall, automated assembly lines play an important role in many industries. They help manufacturers to improve their productivity, quality, costs, safety, and environmental impact.

Automotive

Automotive automated assembly lines are used to assemble cars, trucks, and other vehicles in a fast and efficient manner. They typically consist of a series of workstations connected by a conveyor belt. At each workstation, robots or other automated machines perform specific tasks, such as welding body panels, painting car bodies, and installing engines and other components.

Some of the specific applications of automated assembly lines in the automotive industry include:

- Body welding: Robots weld the stamped metal body panels together to form the chassis of the vehicle.

- Painting: Robots apply a primer, base coat, and clear coat to the vehicle body to protect it from corrosion and give it a finished appearance.

- Powertrain assembly: Robots and other automated machines assemble the engine, transmission, and drivetrain components.

- Chassis assembly: Robots and other automated machines assemble the suspension, steering, and braking systems.

- Trim and final assembly: Robots and other automated machines install the interior and exterior trim, seats, and other components.

Automotive automated assembly lines offer a number of benefits over manual assembly lines, including:

- Increased productivity: Automated assembly lines can run faster and more efficiently than manual assembly lines, resulting in increased productivity.

- Improved quality: Automated assembly lines can help to improve product quality by reducing the risk of human error.

- Reduced costs: Automated assembly lines can help to reduce costs by reducing the need for manual labor and improving efficiency.

- Increased safety: Automated assembly lines can help to improve safety by reducing the need for workers to interact with dangerous machinery.

Overall, automated assembly lines play a vital role in the automotive industry. They help manufacturers to produce high-quality vehicles in a fast and efficient manner.

Here are some trends in automotive automated assembly lines:

- Increased use of robotics: Robotics is being used more and more in automotive assembly lines. Robots can perform a wider range of tasks than ever before, and they are becoming more precise and reliable.

- Greater integration: Automotive assembly lines are becoming increasingly integrated with other manufacturing systems, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This integration helps to improve the efficiency and accuracy of automotive assembly lines.

- More customization: Automotive assembly lines are being customized more and more to meet the specific needs of each manufacturer. This is especially important for manufacturers of high-end or niche vehicles.

Overall, the trend is towards more robotic, integrated, and customized automotive assembly lines. This is helping manufacturers to improve their productivity, quality, costs, safety, and customization capabilities.

Robotic Assembly Systems

Robotic assembly systems are automated systems that use robots to perform assembly tasks. They are used in a wide variety of industries, including automotive, electronics, food and beverage, and pharmaceuticals.

Robotic assembly systems offer a number of benefits over manual assembly, including:

- Increased productivity: Robotic assembly systems can run faster and more efficiently than manual assembly lines, resulting in increased productivity.

- Improved quality: Robotic assembly systems can help to improve product quality by reducing the risk of human error.

- Reduced costs: Robotic assembly systems can help to reduce costs by reducing the need for manual labor and improving efficiency.

- Increased safety: Robotic assembly systems can help to improve safety by reducing the need for workers to interact with dangerous machinery.

- More flexibility: Robotic assembly systems can be more flexible than manual assembly lines, making it easier to produce different products on the same line.

Robotic assembly systems can be customized to meet the specific needs of each manufacturer. For example, a robotic assembly system for assembling cars may be different from a robotic assembly system for assembling smartphones. Robotic assembly systems can also be designed to accommodate a variety of different assembly tasks.

Here are some specific examples of robotic assembly system applications:

- Automotive: Robotic assembly systems are widely used in the automotive industry to assemble cars, trucks, and other vehicles. Robots perform a variety of tasks on automotive assembly lines, such as welding body panels, painting car bodies, and installing engines and other components.

- Electronics: Robotic assembly systems are also widely used in the electronics industry to assemble electronic devices such as smartphones, computers, and televisions. Robots perform a variety of tasks on electronics assembly lines, such as placing components on circuit boards, soldering components together, and testing finished products.

- Food and beverage: Robotic assembly systems are also used in the food and beverage industry to package food and beverages. Robots perform a variety of tasks on food and beverage assembly lines, such as picking and placing food items in containers, filling containers with liquids, and sealing containers.

- Pharmaceuticals: Robotic assembly systems are also used in the pharmaceutical industry to package pharmaceuticals. Robots perform a variety of tasks on pharmaceutical assembly lines, such as picking and placing pharmaceutical products in containers, filling containers with pharmaceutical products, and sealing containers.

Robotic assembly systems play an important role in many industries. They help manufacturers to improve their productivity, quality, costs, safety, and flexibility.

Here are some trends in robotic assembly systems:

- Increased use of collaborative robots: Collaborative robots, also known as cobots, are robots that can work safely alongside human workers. Cobots are becoming increasingly popular in robotic assembly systems because they can be used to perform tasks that are difficult or dangerous for human workers.

- Greater integration: Robotic assembly systems are becoming increasingly integrated with other manufacturing systems, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This integration helps to improve the efficiency and accuracy of robotic assembly systems.

- More customization: Robotic assembly systems are being customized more and more to meet the specific needs of each manufacturer. This is especially important for manufacturers of high-end or niche products.

Overall, the trend is towards more collaborative, integrated, and customized robotic assembly systems. This is helping manufacturers to improve their productivity, quality, costs, safety, and flexibility.

Conveyor Belt Assembly Systems

Conveyor belt assembly systems are automated systems that use conveyor belts to transport products through a series of assembly stations. At each station, workers or robots perform assembly tasks on the products. Conveyor belt assembly systems are used in a wide variety of industries, including automotive, electronics, food and beverage, and pharmaceuticals.

Conveyor belt assembly systems offer a number of benefits over manual assembly, including:

- Increased productivity: Conveyor belt assembly systems can help to increase productivity by keeping products moving and preventing workers from having to walk back and forth to get parts and tools.

- Improved quality: Conveyor belt assembly systems can help to improve product quality by reducing the risk of human error.

- Reduced costs: Conveyor belt assembly systems can help to reduce costs by improving efficiency and reducing the need for manual labor.

- Increased safety: Conveyor belt assembly systems can help to improve safety by reducing the need for workers to reach or lift heavy objects.

Conveyor belt assembly systems can be customized to meet the specific needs of each manufacturer. For example, a conveyor belt assembly system for assembling cars may be different from a conveyor belt assembly system for assembling smartphones. Conveyor belt assembly systems can also be designed to accommodate a variety of different assembly tasks.

Here are some specific examples of conveyor belt assembly system applications:

- Automotive: Conveyor belt assembly systems are widely used in the automotive industry to assemble cars, trucks, and other vehicles. Products are transported down the conveyor belt and workers or robots perform assembly tasks such as welding body panels, painting car bodies, and installing engines and other components.

- Electronics: Conveyor belt assembly systems are also widely used in the electronics industry to assemble electronic devices such as smartphones, computers, and televisions. Products are transported down the conveyor belt and workers or robots perform assembly tasks such as placing components on circuit boards, soldering components together, and testing finished products.

- Food and beverage: Conveyor belt assembly systems are also used in the food and beverage industry to package food and beverages. Products are transported down the conveyor belt and workers or robots perform assembly tasks such as picking and placing food items in containers, filling containers with liquids, and sealing containers.

- Pharmaceuticals: Conveyor belt assembly systems are also used in the pharmaceutical industry to package pharmaceuticals. Products are transported down the conveyor belt and workers or robots perform assembly tasks such as picking and placing pharmaceutical products in containers, filling containers with pharmaceutical products, and sealing containers.

Conveyor belt assembly systems play an important role in many industries. They help manufacturers to improve their productivity, quality, costs, safety, and efficiency.

Here are some trends in conveyor belt assembly systems:

- Increased use of automation: More and more conveyor belt assembly systems are being automated with robots and other automated machines. This is helping manufacturers to improve their productivity and quality.

- Greater integration: Conveyor belt assembly systems are becoming increasingly integrated with other manufacturing systems, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This integration helps to improve the efficiency and accuracy of conveyor belt assembly systems.

- More customization: Conveyor belt assembly systems are being customized more and more to meet the specific needs of each manufacturer. This is especially important for manufacturers of high-end or niche products.

Overall, the trend is towards more automated, integrated, and customized conveyor belt assembly systems. This is helping manufacturers to improve their productivity, quality, costs, safety, and efficiency.

Automated Assembly Machines

The precision dance of automated assembly reaches new heights with the integration of Computer Numerical Control (CNC) systems. These systems contribute meticulous control over machining processes, influencing the production of intricate components across various industries. In the realm of automated assembly, CNC systems play a pivotal role in shaping the intricate details of manufacturing with unparalleled accuracy.

Motion Control, another key player in this orchestration, governs the nuanced movement of machinery. Whether it’s the articulate motion of robotic arms in assembly processes or the controlled movement of conveyor systems, the synchronization facilitated by Motion Control ensures tasks are executed with efficiency and accuracy.

Industrial Robots, including SCARA robots, showcase the epitome of automated precision. These versatile entities execute tasks across industries, contributing to the seamless integration of automated systems within the broader context of industrial processes. Their precision and agility make them indispensable in tasks ranging from assembly to intricate manufacturing processes.

Collaborative Robots (Cobots) mark a transformative frontier in human-robot collaboration. Operating seamlessly alongside human counterparts, Cobots exemplify a harmonious interaction, enhancing efficiency and safety in shared workspaces. The collaborative nature of these interactions fosters adaptability and flexibility in industrial settings, where human expertise and robotic precision converge seamlessly.

In this dynamic landscape, the interconnected principles of the Industrial Internet of Things (IIoT) and Industry 4.0 continue to shape the future. The integration of smart devices and data-driven decision-making ensures that manufacturing processes adapt to real-time insights, optimizing efficiency and paving the way for the next era of industrial automation.

Automated assembly machines are machines that use robotics, sensors, and other technologies to perform assembly tasks without human intervention. They are used in a wide variety of industries, including automotive, electronics, food and beverage, and pharmaceuticals.

Automated assembly machines offer a number of benefits over manual assembly, including:

- Increased productivity: Automated assembly machines can run faster and more efficiently than manual assembly lines, resulting in increased productivity.

- Improved quality: Automated assembly machines can help to improve product quality by reducing the risk of human error.

- Reduced costs: Automated assembly machines can help to reduce costs by reducing the need for manual labor and improving efficiency.

- Increased safety: Automated assembly machines can help to improve safety by reducing the need for workers to interact with dangerous machinery.

- More flexibility: Automated assembly machines can be more flexible than manual assembly lines, making it easier to produce different products on the same machine.

Automated assembly machines can be customized to meet the specific needs of each manufacturer. For example, an automated assembly machine for assembling cars may be different from an automated assembly machine for assembling smartphones. Automated assembly machines can also be designed to accommodate a variety of different assembly tasks.

Here are some specific examples of automated assembly machine applications:

- Automotive: Automated assembly machines are widely used in the automotive industry to assemble cars, trucks, and other vehicles. Robots perform a variety of tasks on automated assembly machines, such as welding body panels, painting car bodies, and installing engines and other components.

- Electronics: Automated assembly machines are also widely used in the electronics industry to assemble electronic devices such as smartphones, computers, and televisions. Robots perform a variety of tasks on automated assembly machines, such as placing components on circuit boards, soldering components together, and testing finished products.

- Food and beverage: Automated assembly machines are also used in the food and beverage industry to package food and beverages. Robots perform a variety of tasks on automated assembly machines, such as picking and placing food items in containers, filling containers with liquids, and sealing containers.

- Pharmaceuticals: Automated assembly machines are also used in the pharmaceutical industry to package pharmaceuticals. Robots perform a variety of tasks on automated assembly machines, such as picking and placing pharmaceutical products in containers, filling containers with pharmaceutical products, and sealing containers.

Automated assembly machines play an important role in many industries. They help manufacturers to improve their productivity, quality, costs, safety, and flexibility.

Here are some trends in automated assembly machines:

- Increased use of collaborative robots: Collaborative robots, also known as cobots, are robots that can work safely alongside human workers. Cobots are becoming increasingly popular in automated assembly machines because they can be used to perform tasks that are difficult or dangerous for human workers.

- Greater integration: Automated assembly machines are becoming increasingly integrated with other manufacturing systems, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This integration helps to improve the efficiency and accuracy of automated assembly machines.

- More customization: Automated assembly machines are being customized more and more to meet the specific needs of each manufacturer. This is especially important for manufacturers of high-end or niche products.

Overall, the trend is towards more collaborative, integrated, and customized automated assembly machines. This is helping manufacturers to improve their productivity, quality, costs, safety, and flexibility.

EMS Automation Solutions

Introducing EMS Automation Solutions: Pioneering Excellence in Industrial Automation

At EMS Automation Solutions, we stand at the forefront of innovation, offering cutting-edge industrial automation solutions that redefine the way industries operate. With a relentless commitment to precision, efficiency, and reliability, we empower businesses to navigate the complexities of the modern industrial landscape seamlessly.

Comprehensive Industrial Automation Portfolio

Our extensive portfolio encompasses a diverse range of industrial automation solutions tailored to meet the unique needs of our clients. From PLC (Programmable Logic Controller) programming to SCADA (Supervisory Control and Data Acquisition) systems, robotics, and state-of-the-art control valves, we deliver holistic automation solutions that drive productivity and operational excellence.

PLC Programming Excellence

Unlock the full potential of your industrial processes with our unparalleled PLC programming expertise. Our skilled team of engineers crafts custom solutions that optimize control, enhance reliability, and streamline processes. From designing intricate control logic to seamless integration with other automation components, our PLC solutions are tailored to elevate your production capabilities.

SCADA Systems for Real-Time Control

Experience real-time control and monitoring like never before with our SCADA systems. EMS Automation Solutions leverages advanced SCADA technologies to provide a centralized platform for overseeing and managing diverse industrial processes. Gain insights, analyze data, and make informed decisions to propel your business into a new era of efficiency.

Robotics Redefined

Embrace the future of manufacturing with our state-of-the-art robotics solutions. From automated assembly lines to intricate tasks requiring precision, our robotics systems are engineered to enhance speed, accuracy, and safety in your operations. Collaborative robots, robotic arms, and automated guided vehicles – we bring a spectrum of robotics solutions to elevate your manufacturing prowess.

Control Valves for Precision Flow Management

Ensure optimal fluid flow control with our premium control valves. Whether it’s mitigating cavitation, addressing flashing issues, or managing noise levels, EMS Automation Solutions provides a comprehensive range of control valves designed for durability, efficiency, and precise control. Our valves are crafted to seamlessly integrate into your processes, offering reliability in every operation.

Global Reach, Local Expertise

With a global presence, EMS Automation Solutions combines international reach with local expertise. Our teams collaborate closely with clients to understand their unique challenges and deliver bespoke solutions. From conceptualization to implementation and ongoing support, we are your trusted partner throughout the automation journey.

Sustainable Automation Practices

EMS Automation Solutions is committed to sustainable automation practices. We incorporate energy-efficient technologies, promote waste reduction, and design automation solutions that align with eco-friendly principles. Join us in building a future where automation and sustainability go hand in hand.

Partner with EMS Automation Solutions for Tomorrow’s Automation Today

As industries evolve, so do we. EMS Automation Solutions is not just a provider of automation services – we are architects of innovation, architects of efficiency, and architects of your success. Partner with us to transform your industrial processes and embark on a journey towards unparalleled automation excellence. Elevate your operations with EMS Automation Solutions – where the future of automation begins today!