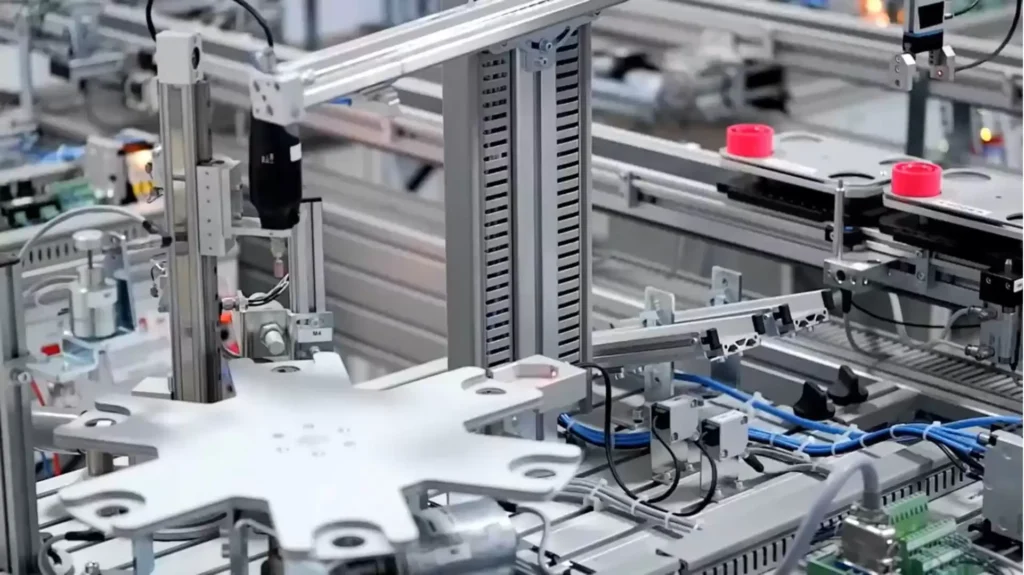

We, as EMS Automation Solutions, offer a wide range of solutions to help businesses improve their efficiency and productivity. Some of the most common solutions include:

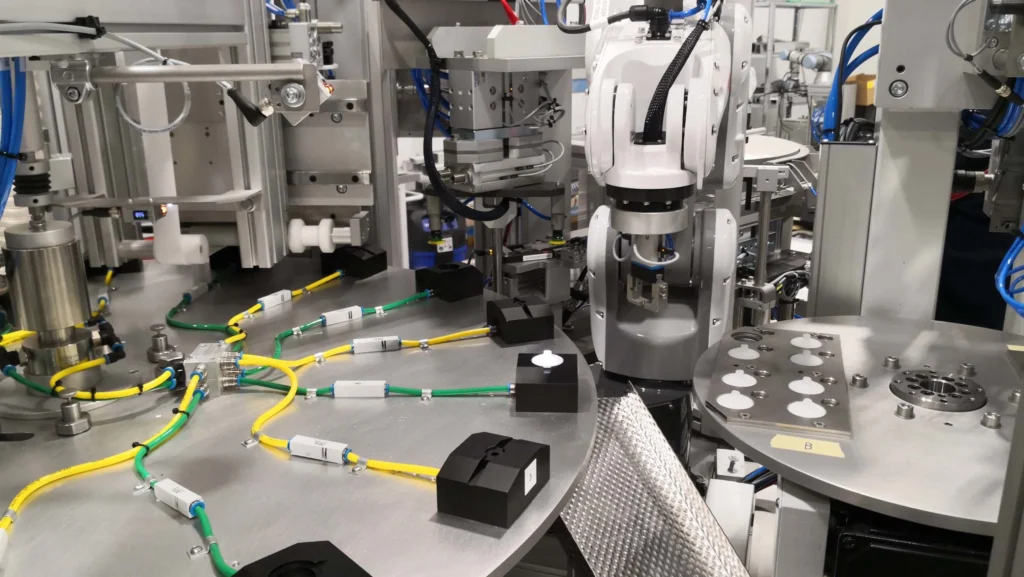

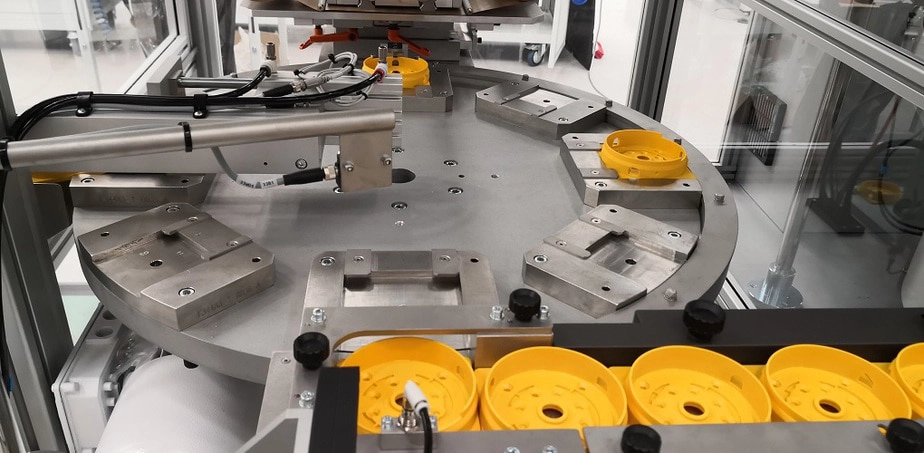

- Industrial robotics: Industrial robots can be used to automate a variety of tasks, such as welding, painting, assembly, and packaging. This can help to improve the quality and consistency of products, while also reducing labor costs.

- Machine vision systems: Machine vision systems can be used to inspect products for defects, track objects on assembly lines, and guide robots to perform tasks. This can help to improve product quality and reduce waste.

- Process control systems: Process control systems can be used to monitor and control industrial processes, such as temperature, pressure, and flow. This can help to improve the efficiency and safety of these processes.

- Data analytics: Data analytics can be used to collect and analyze data from industrial processes. This information can then be used to improve the efficiency and productivity of these processes.

In addition to these standard solutions, machinery and process automation companies may also offer custom solutions to meet the specific needs of their customers. For example, a company may develop a custom robotic system to automate a unique manufacturing process.

Here are some specific examples of solutions that a machinery and process automation company may offer:

- Robotic welding system: A robotic welding system can be used to automate the welding process, which can help to improve the quality and consistency of welds, while also reducing labor costs.

- Machine vision system for inspecting products: A machine vision system can be used to inspect products for defects, such as cracks, dents, and scratches. This can help to improve product quality and reduce waste.

- Process control system for a food processing plant: A process control system can be used to monitor and control the temperature, pressure, and flow of ingredients in a food processing plant. This can help to improve the efficiency and safety of the food processing process.

- Data analytics solution for a manufacturing plant: A data analytics solution can be used to collect and analyze data from a manufacturing plant, such as machine downtime, product defects, and production rates. This information can then be used to improve the efficiency and productivity of the manufacturing plant.

Machinery and process automation companies can help businesses of all sizes to improve their efficiency and productivity. By automating tasks, improving product quality, and reducing waste, these companies can help businesses to save money and become more competitive.

Here below, you may find more information about each of the solutions

Industrial Robotics

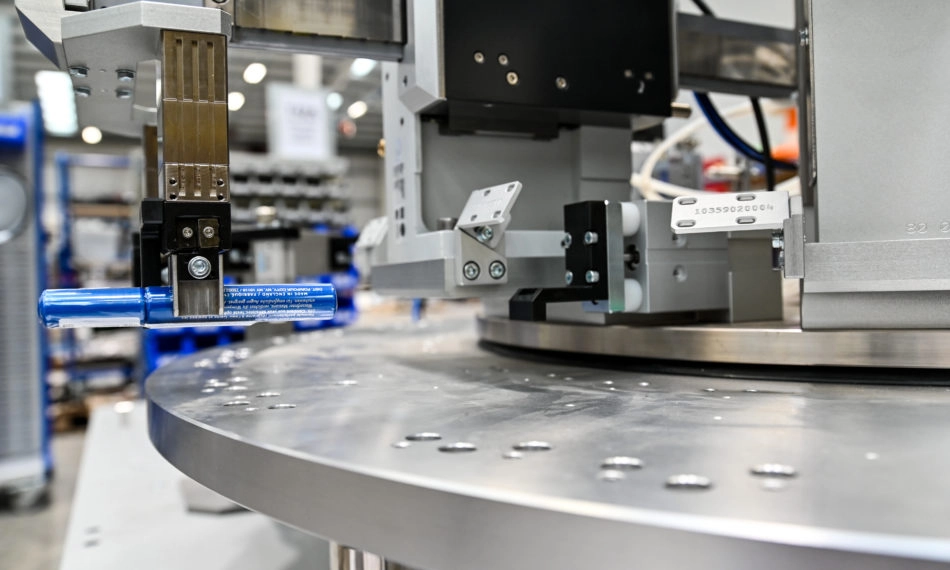

Industrial robotics is the use of robots in manufacturing and other industrial settings. Industrial robots are typically programmed to perform repetitive tasks with high precision and accuracy. They can be used to automate a wide range of tasks, including:

- Welding

- Painting

- Assembly

- Packaging

- Material handling

- Inspection

- Machine tending

Industrial robots are becoming increasingly common in manufacturing, as they can help to improve efficiency, productivity, and quality. They can also be used to perform tasks that are dangerous or difficult for humans to do.

Here are some of the benefits of using industrial robots:

- Increased productivity: Industrial robots can work faster and more consistently than humans, which can lead to significant increases in productivity.

- Improved quality: Industrial robots can perform tasks with a high degree of precision and accuracy, which can lead to improvements in product quality.

- Reduced costs: Industrial robots can help to reduce labor costs, as they can automate tasks that would otherwise be performed by humans.

- Improved safety: Industrial robots can be used to perform tasks that are dangerous or difficult for humans to do, which can improve safety in the workplace.

Industrial robots are available in a variety of sizes and configurations, and can be customized to meet the specific needs of a particular application. They are used in a wide range of industries, including automotive, electronics, food and beverage, and pharmaceuticals.

Here are some examples of how industrial robots are being used today:

- In the automotive industry, industrial robots are used to weld car bodies, paint cars, and assemble cars.

- In the electronics industry, industrial robots are used to assemble circuit boards and other electronic components.

- In the food and beverage industry, industrial robots are used to package food and beverages, and to palletize products for shipping.

- In the pharmaceutical industry, industrial robots are used to package drugs and other pharmaceutical products.

Industrial robots are a key part of modern manufacturing, and they are playing an increasingly important role in helping businesses to improve their efficiency, productivity, and quality.

Machine Vision Systems

Machine vision systems are computer-based systems that use cameras to capture images and videos, and then process these images and videos to extract information. Machine vision systems are used in a wide range of applications, including:

- Industrial inspection: Machine vision systems are used to inspect products for defects, such as cracks, dents, and scratches. This can help to improve product quality and reduce waste.

- Process control: Machine vision systems are used to monitor and control industrial processes, such as the assembly of products and the packaging of products. This can help to improve the efficiency and safety of these processes.

- Robotics: Machine vision systems are used to guide robots to perform tasks, such as welding, painting, and assembly. This can help to improve the quality and consistency of products, while also reducing labor costs.

- Security: Machine vision systems are used to monitor security cameras and to detect intruders. This can help to improve security and reduce crime.

Machine vision systems are becoming increasingly common in a wide range of industries, as they can help to improve efficiency, productivity, and quality. They can also be used to perform tasks that are dangerous or difficult for humans to do.

Here are some of the benefits of using machine vision systems:

- Improved quality: Machine vision systems can be used to inspect products for defects with a high degree of precision and accuracy, which can lead to improvements in product quality.

- Reduced costs: Machine vision systems can help to reduce labor costs, as they can automate tasks that would otherwise be performed by humans.

- Improved safety: Machine vision systems can be used to monitor industrial processes and to detect hazards, which can improve safety in the workplace.

- Increased productivity: Machine vision systems can help to improve productivity by automating tasks and by providing real-time feedback on production processes.

Machine vision systems are available in a variety of sizes and configurations, and can be customized to meet the specific needs of a particular application. They are used in a wide range of industries, including automotive, electronics, food and beverage, and pharmaceuticals.

Here are some examples of how machine vision systems are being used today:

- In the automotive industry, machine vision systems are used to inspect car bodies for defects, such as dents and scratches.

- In the electronics industry, machine vision systems are used to inspect circuit boards for defects, such as missing components and incorrect solder joints.

- In the food and beverage industry, machine vision systems are used to inspect food and beverages for defects, such as foreign objects and contamination.

- In the pharmaceutical industry, machine vision systems are used to inspect drugs and other pharmaceutical products for defects, such as missing pills and incorrect packaging.

Machine vision systems are a key part of modern manufacturing, and they are playing an increasingly important role in helping businesses to improve their efficiency, productivity, and quality.

Process Control Systems and Solutions

Process control systems (PCS) are computer-based systems that monitor and control industrial processes. PCSs are used in a wide range of industries, including automotive, chemical, food and beverage, and pharmaceuticals.

PCSs typically consist of the following components:

- Sensors: Sensors are used to measure process variables, such as temperature, pressure, and flow.

- Controllers: Controllers are used to receive data from the sensors and to send control signals to the actuators.

- Actuators: Actuators are used to control the process variables by adjusting valves, motors, and other devices.

- Software: Software is used to monitor and control the overall process, and to provide feedback to the controllers.

PCSs can be used to control a wide range of processes, including:

- Temperature control: PCSs can be used to control the temperature of industrial processes, such as the temperature of a chemical reactor or the temperature of a furnace.

- Pressure control: PCSs can be used to control the pressure of industrial processes, such as the pressure of a hydraulic system or the pressure of a pneumatic system.

- Flow control: PCSs can be used to control the flow of fluids and gases in industrial processes, such as the flow of oil in a pipeline or the flow of air in a ventilation system.

PCSs can be used to improve the efficiency, productivity, and quality of industrial processes. They can also be used to improve safety by reducing the risk of accidents.

Here are some of the benefits of using PCSs:

- Improved efficiency: PCSs can help to improve the efficiency of industrial processes by automating tasks and by providing real-time feedback on production processes.

- Increased productivity: PCSs can help to increase productivity by automating tasks and by reducing waste.

- Improved quality: PCSs can help to improve the quality of products by ensuring that the process variables are maintained within the desired range.

- Reduced costs: PCSs can help to reduce costs by reducing waste and by improving efficiency.

- Improved safety: PCSs can help to improve safety by reducing the risk of accidents.

PCSs are available in a variety of sizes and configurations, and can be customized to meet the specific needs of a particular application. They are used in a wide range of industries, including automotive, chemical, food and beverage, and pharmaceuticals.

Here are some examples of how PCSs are being used today:

- In the automotive industry, PCSs are used to control the temperature, pressure, and flow of fluids and gases in the manufacturing process.

- In the chemical industry, PCSs are used to control the temperature, pressure, and flow of chemicals in the production process.

- In the food and beverage industry, PCSs are used to control the temperature, pressure, and flow of food and beverages in the production process.

- In the pharmaceutical industry, PCSs are used to control the temperature, pressure, and flow of drugs and other pharmaceutical products in the production process.

PCSs are a key part of modern manufacturing, and they are playing an increasingly important role in helping businesses to improve their efficiency, productivity, quality, and safety.

Data Analytics Solutions

Data analytics is the process of collecting, cleaning, and analyzing data to extract meaningful insights. It is a powerful tool that can be used to improve decision-making in a wide range of industries, including machinery and process automation.

There are many different types of data analytics, but some of the most common include:

- Descriptive analytics: Descriptive analytics is used to summarize and describe data. It can be used to answer questions such as “What happened?” and “Why did it happen?”

- Diagnostic analytics: Diagnostic analytics is used to identify the root cause of problems or deviations from expected results. It can be used to answer questions such as “Why is this happening?” and “What can we do to fix it?”

- Predictive analytics: Predictive analytics is used to predict future outcomes based on historical data. It can be used to answer questions such as “What is likely to happen?” and “What actions should we take to achieve our desired outcome?”

- Prescriptive analytics: Prescriptive analytics is used to recommend the best course of action based on historical data and predicted outcomes. It can be used to answer questions such as “What should we do now?” and “How can we improve our results?”

Data analytics can be used to improve machinery and process automation in a number of ways. For example, data analytics can be used to:

- Optimize machine settings: Data analytics can be used to identify the optimal settings for machines to improve performance and efficiency.

- Predict machine failures: Data analytics can be used to predict when machines are likely to fail, so that preventive maintenance can be performed.

- Identify bottlenecks in production processes: Data analytics can be used to identify bottlenecks in production processes, so that they can be eliminated or improved.

- Improve product quality: Data analytics can be used to identify and eliminate the root causes of product defects.

- Reduce costs: Data analytics can be used to identify and eliminate waste and inefficiency in production processes.

Data analytics is a powerful tool that can be used to improve machinery and process automation in a number of ways. By collecting and analyzing data, businesses can gain valuable insights that can help them to improve their performance, efficiency, and profitability.

Here are some examples of how data analytics is being used in machinery and process automation today:

- A manufacturing company uses data analytics to identify the optimal settings for its machines to improve production speed and efficiency.

- A food and beverage company uses data analytics to predict when its machines are likely to fail, so that preventive maintenance can be performed.

- A chemical company uses data analytics to identify bottlenecks in its production processes, so that they can be eliminated or improved.

- A pharmaceutical company uses data analytics to identify and eliminate the root causes of product defects.

- A transportation company uses data analytics to optimize its delivery routes and reduce costs.

Data analytics is a rapidly growing field, and there are many new and innovative applications for it in machinery and process automation. As data becomes more and more accessible, businesses of all sizes will be able to use data analytics to improve their performance.