Automated assembly for consumer products is the use of robots and other machines to assemble products without human intervention. This is a rapidly growing field, as businesses look for ways to improve efficiency and reduce costs.

Automated assembly lines can be used to assemble a wide range of consumer products, including:

- Electronics: smartphones, tablets, TVs, laptops, etc.

- Appliances: refrigerators, washing machines, dryers, etc.

- Automotive parts: engines, transmissions, dashboards, etc.

- Food and beverage products: bottled water, soda, canned goods, etc.

- Pharmaceuticals: drugs, medical devices, etc.

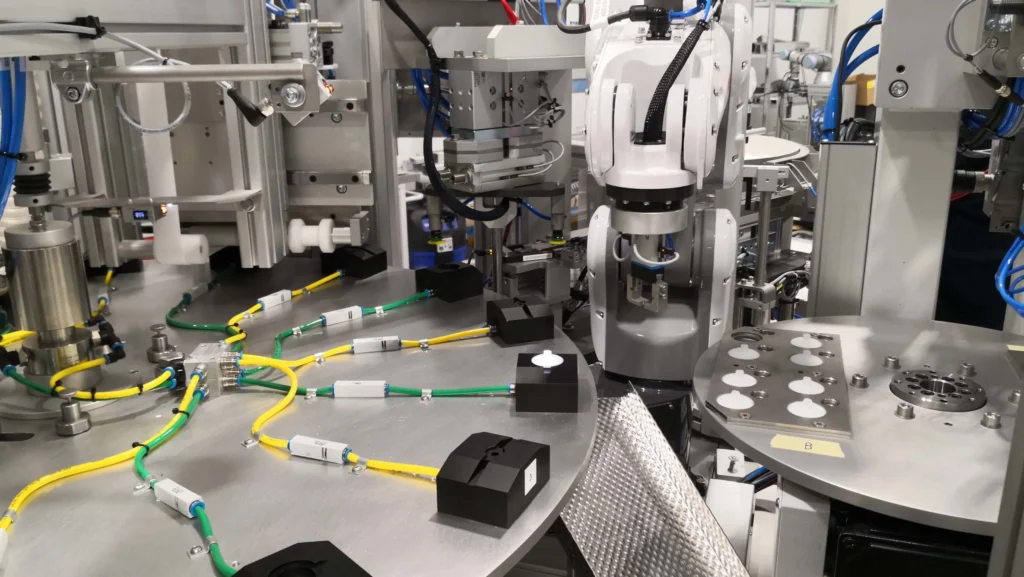

Automated assembly lines typically consist of a series of workstations, each of which performs a specific task in the assembly process. For example, one workstation might pick and place components onto a circuit board, while another workstation might solder the components together. The workstations are linked together by a conveyor belt, which moves the products from one workstation to the next.

Automated assembly lines are controlled by a computer system, which monitors the progress of the products through the assembly line and ensures that each task is completed correctly. The computer system can also be used to collect data about the assembly process, which can be used to improve efficiency and quality.

Automated assembly offers a number of benefits for businesses, including:

- Increased productivity: Automated assembly lines can help to increase productivity by automating repetitive and time-consuming tasks.

- Improved quality: Automated assembly lines can help to improve quality by reducing the risk of human error.

- Reduced costs: Automated assembly lines can help to reduce costs by reducing labor costs and by improving efficiency.

- Improved safety: Automated assembly lines can help to improve safety by reducing the risk of workplace accidents.

Automated assembly is a key part of modern manufacturing, and it is playing an increasingly important role in helping businesses to improve their efficiency, productivity, quality, and safety.

Here are some examples of how automated assembly is being used to manufacture consumer products:

- Electronics: Apple uses automated assembly lines to assemble its iPhones and other electronic devices. The assembly lines are able to assemble millions of devices each year with great precision and accuracy.

- Appliances: Samsung uses automated assembly lines to assemble its refrigerators, washing machines, and other appliances. The assembly lines are able to assemble thousands of appliances each day with high quality.

- Automotive parts: Tesla uses automated assembly lines to assemble its electric vehicles. The assembly lines are able to assemble hundreds of vehicles each day with great precision and accuracy.

- Food and beverage products: Coca-Cola uses automated assembly lines to fill and package its bottles and cans of soda. The assembly lines are able to fill and package millions of bottles and cans each hour.

- Pharmaceuticals: Pfizer uses automated assembly lines to manufacture and package its drugs. The assembly lines are able to manufacture and package millions of doses of drugs each day with high quality.

Automated assembly is a rapidly growing field, and we can expect to see even more innovative and sophisticated automated assembly lines in the future.

Automated Assembly Applications

- Apple: Apple uses automated assembly lines to assemble its iPhones and other electronic devices. The assembly lines are able to assemble millions of devices each year with great precision and accuracy.

For example, Apple’s iPhone assembly line uses robotic arms to pick and place components onto the circuit board, as well as to solder the components together. The assembly line also uses vision systems to inspect the devices for defects.

- Samsung: Samsung uses automated assembly lines to assemble its refrigerators, washing machines, and other appliances. The assembly lines are able to assemble thousands of appliances each day with high quality.

For example, Samsung’s refrigerator assembly line uses robotic arms to pick and place components onto the refrigerator frame, as well as to attach the doors and shelves. The assembly line also uses testing stations to ensure that the refrigerators are working properly.

- Tesla: Tesla uses automated assembly lines to assemble its electric vehicles. The assembly lines are able to assemble hundreds of vehicles each day with great precision and accuracy.

For example, Tesla’s Model 3 assembly line uses robotic arms to weld the body panels together, as well as to install the battery pack and electric motor. The assembly line also uses testing stations to ensure that the vehicles are working properly.

- Coca-Cola: Coca-Cola uses automated assembly lines to fill and package its bottles and cans of soda. The assembly lines are able to fill and package millions of bottles and cans each hour.

For example, Coca-Cola’s soda bottling line uses robotic arms to pick and place empty bottles onto the conveyor belt, as well as to fill the bottles with soda and cap them. The assembly line also uses testing stations to ensure that the bottles are filled properly and that the caps are sealed tightly.

- Pfizer: Pfizer uses automated assembly lines to manufacture and package its drugs. The assembly lines are able to manufacture and package millions of doses of drugs each day with high quality.

For example, Pfizer’s vaccine manufacturing line uses robotic arms to pick and place components into the vaccine vials, as well as to fill the vials with vaccine and cap them. The assembly line also uses testing stations to ensure that the vaccines are manufactured properly and that the vials are sealed tightly.

Automated assembly is a rapidly growing field, and we can expect to see even more innovative and sophisticated automated assembly lines in the future. As automation technology continues to develop, we can expect to see automated assembly lines that are able to assemble a wider range of products with greater precision and accuracy.

PLC in automated assemblies for consumer products

A programmable logic controller (PLC) is a digital computer used for industrial automation of electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many industries and machines. Unlike general-purpose computers, the PLC is designed for multiple inputs and output arrangements, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed or non-volatile memory. A PLC is an example of a real-time system since output results must be produced in response to input conditions within a limited time, otherwise unintended operation will result.

In automated assemblies for consumer products, PLCs are used to control the various machines and processes that make up the assembly line. For example, a PLC might be used to control the movement of the conveyor belt, the operation of the robotic arms, and the timing of the various assembly steps.

PLCs are well-suited for use in automated assemblies because they are:

- Reliable: PLCs are designed to operate in harsh industrial environments. They are resistant to vibration, shock, and electrical noise.

- Flexible: PLCs can be programmed to perform a wide variety of tasks. This makes them ideal for use in automated assemblies, which can be very complex.

- Scalable: PLCs can be scaled to meet the needs of any size automated assembly. From small assemblies with a few machines to large assemblies with hundreds of machines, PLCs can be used to control the entire process.

Here are some specific examples of how PLCs are used in automated assemblies for consumer products:

- Food and beverage: PLCs are used to control the filling, packaging, and palletizing of food and beverage products.

- Pharmaceuticals: PLCs are used to control the manufacturing and packaging of pharmaceuticals.

- Electronics: PLCs are used to control the assembly and testing of electronic devices.

- Automotive: PLCs are used to control the welding, painting, and assembly of automotive parts.

PLCs are an essential part of automated assemblies for consumer products. They help to ensure that the products are assembled efficiently and accurately, and that the assembly process is safe.

Here are some of the benefits of using PLCs in automated assemblies for consumer products:

- Increased productivity: PLCs can help to increase productivity by automating repetitive and time-consuming tasks.

- Improved quality: PLCs can help to improve quality by reducing the risk of human error.

- Reduced costs: PLCs can help to reduce costs by reducing labor costs and by improving efficiency.

- Improved safety: PLCs can help to improve safety by reducing the risk of workplace accidents.

Overall, PLCs are a valuable tool for businesses that use automated assemblies for consumer products. By using PLCs, businesses can improve their efficiency, productivity, quality, and safety.

Sensor technology refers to the science and engineering of developing, designing, and utilizing sensors to detect, measure, and respond to various physical stimuli or environmental conditions. Sensors are devices that convert physical quantities, such as temperature, pressure, light, sound, or motion, into electrical signals that can be processed, analyzed, or used to control other systems. Sensor technology plays a crucial role in a wide range of applications across industries, including manufacturing, healthcare, automotive, aerospace, environmental monitoring, and consumer electronics. Here’s an overview of sensor technology:

- Basic Components:

- Sensing Element: The sensing element is the core component of a sensor that interacts with the physical quantity being measured. It undergoes a change in response to the stimulus, producing an output signal proportional to the input.

- Transducer: The transducer converts the physical change detected by the sensing element into an electrical signal. It may use various principles such as resistive, capacitive, inductive, piezoelectric, or optical mechanisms to generate the output signal.

- Signal Conditioning Circuitry: Signal conditioning circuitry processes and amplifies the electrical signal generated by the transducer to improve accuracy, resolution, and compatibility with measurement or control systems.

- Output Interface: The output interface provides a means to transmit the processed electrical signal to external devices or systems for further processing, display, or analysis. Common output interfaces include analog voltage or current signals, digital signals, or wireless communication protocols.

- Types of Sensors:

- Temperature Sensors: Temperature sensors measure temperature variations and are used in applications such as HVAC systems, industrial processes, automotive engines, and medical devices.

- Pressure Sensors: Pressure sensors detect changes in pressure levels and find applications in pressure monitoring, altitude sensing, leak detection, and pneumatic systems.

- Force Sensors: Force sensors measure force or load exerted on an object and are used in applications such as robotics, material testing, and medical devices.

- Motion Sensors: Motion sensors detect movement or changes in position and are employed in security systems, gaming consoles, automotive safety systems, and industrial automation.

- Proximity Sensors: Proximity sensors detect the presence or absence of nearby objects without physical contact and are used in object detection, automation, and robotics.

- Light Sensors: Light sensors measure ambient light levels or detect changes in light intensity and find applications in automatic lighting systems, photography, and optical devices.

- Gas Sensors: Gas sensors detect the presence or concentration of gases in the environment and are used in gas detection, air quality monitoring, and industrial safety systems.

- Biometric Sensors: Biometric sensors measure unique biological characteristics such as fingerprints, iris patterns, or facial features and are used in security systems, access control, and personal electronic devices.

- Chemical Sensors: Chemical sensors detect specific chemical compounds or analytes and find applications in environmental monitoring, industrial processes, and medical diagnostics.

- Advanced Sensor Technologies:

- MEMS (Micro-Electro-Mechanical Systems) Sensors: MEMS sensors are miniaturized devices that integrate mechanical and electrical components on a single chip, enabling compact and low-cost sensor solutions.

- Wireless Sensors: Wireless sensors use wireless communication protocols such as Bluetooth, Wi-Fi, Zigbee, or LoRa to transmit data without physical connections, enabling remote monitoring and IoT applications.

- Smart Sensors: Smart sensors incorporate built-in signal processing, data analysis, or self-diagnostic capabilities, providing real-time insights and facilitating autonomous operation.

- IoT Sensors: IoT (Internet of Things) sensors are interconnected sensors that collect data and communicate with each other or with cloud-based platforms for data analytics, predictive maintenance, and smart city applications.

- Optical Sensors: Optical sensors utilize light-based principles such as absorption, reflection, or refraction to detect and measure physical quantities, offering high sensitivity, accuracy, and reliability in diverse applications.

- Nanotechnology-Based Sensors: Nanotechnology enables the development of sensors with nanoscale features or structures, offering enhanced sensitivity, selectivity, and miniaturization for advanced sensing applications.

- Applications:

- Industrial Automation: Sensors are extensively used in industrial automation for process monitoring, control, and optimization in manufacturing, energy, and transportation systems.

- Healthcare and Medical Devices: Sensors play a vital role in medical diagnostics, patient monitoring, wearable health devices, and imaging systems for detecting physiological parameters.

- Automotive Systems: Sensors are integral to automotive systems for engine management, emissions control, safety features, navigation, and driver assistance systems.

- Environmental Monitoring: Sensors are deployed in environmental monitoring networks to measure air quality, water quality, pollution levels, weather parameters, and seismic activity.

- Consumer Electronics: Sensors are incorporated into smartphones, tablets, wearables, and smart home devices for touch sensing, gesture recognition, motion tracking, and ambient light sensing.

- Agriculture and Food Industry: Sensors are used in precision agriculture for soil monitoring, irrigation control, crop health assessment, and food quality inspection throughout the supply chain.

Sensor technology continues to evolve rapidly, driven by advancements in materials science, electronics, nanotechnology, and data analytics. Emerging trends such as wearable sensors, IoT connectivity, and AI-powered analytics are reshaping industries and unlocking new opportunities for sensor applications in diverse fields.

Automation

Automation refers to the process of utilizing technology to perform tasks with minimal human intervention. In the context of robotics, automation involves the design and implementation of systems that can operate autonomously or semi-autonomously to carry out various tasks. These tasks can range from simple repetitive actions to complex operations requiring decision-making capabilities.

In industrial settings, automation plays a crucial role in enhancing efficiency, productivity, and safety. Automated systems often include a combination of hardware components such as sensors, actuators, controllers, and software algorithms. These components work together to monitor the environment, process data, and execute predefined actions.