Industrial automation systems are computer-based systems that monitor and control industrial processes. They are used in a wide range of industries, including automotive, chemical, food and beverage, and pharmaceuticals.

Industrial automation systems typically consist of the following components:

- Sensors: Sensors are used to measure process variables, such as temperature, pressure, and flow.

- Controllers: Controllers are used to receive data from the sensors and to send control signals to the actuators.

- Actuators: Actuators are used to control the process variables by adjusting valves, motors, and other devices.

- Software: Software is used to monitor and control the overall process, and to provide feedback to the controllers.

Industrial automation systems can be used to control a wide range of processes, including:

- Temperature control: Industrial automation systems can be used to control the temperature of industrial processes, such as the temperature of a chemical reactor or the temperature of a furnace.

- Pressure control: Industrial automation systems can be used to control the pressure of industrial processes, such as the pressure of a hydraulic system or the pressure of a pneumatic system.

- Flow control: Industrial automation systems can be used to control the flow of fluids and gases in industrial processes, such as the flow of oil in a pipeline or the flow of air in a ventilation system.

Industrial automation systems can be used to improve the efficiency, productivity, and quality of industrial processes. They can also be used to improve safety by reducing the risk of accidents.

Here are some of the benefits of using industrial automation systems:

- Improved efficiency: Industrial automation systems can help to improve the efficiency of industrial processes by automating repetitive and time-consuming tasks.

- Increased productivity: Industrial automation systems can help to increase productivity by automating tasks and by reducing waste.

- Improved quality: Industrial automation systems can help to improve the quality of products by ensuring that the process variables are maintained within the desired range.

- Reduced costs: Industrial automation systems can help to reduce costs by reducing labor costs and by improving efficiency.

- Improved safety: Industrial automation systems can help to improve safety by reducing the risk of accidents.

Industrial automation systems are a key part of modern manufacturing, and they are playing an increasingly important role in helping businesses to improve their efficiency, productivity, quality, and safety.

Here are some examples of how industrial automation systems are being used today:

- In the automotive industry, industrial automation systems are used to control the temperature, pressure, and flow of fluids and gases in the manufacturing process.

- In the chemical industry, industrial automation systems are used to control the temperature, pressure, and flow of chemicals in the production process.

- In the food and beverage industry, industrial automation systems are used to control the temperature, pressure, and flow of food and beverages in the production process.

- In the pharmaceutical industry, industrial automation systems are used to control the temperature, pressure, and flow of drugs and other pharmaceutical products in the production process.

Industrial automation systems are a rapidly growing field, and there are many new and innovative applications for it. As automation continues to develop, we can expect to see even more businesses using industrial automation systems to improve their operations.

Industrial Automation Systems

In the realm of industrial automation, the foundation lies in the Programmable Logic Controller (PLC), serving as the core for automated processes. These systems are complemented by Supervisory Control and Data Acquisition (SCADA), facilitating real-time monitoring and control. Human-Machine Interface (HMI) enhances interaction, while Manufacturing Execution Systems (MES) optimize overall production efficiency.

Distributed Control Systems (DCS) orchestrate complex industrial processes, and the precision of PID control (Proportional-Integral-Derivative) ensures accurate parameter adjustments. Computer Numerical Control (CNC) enables precise machining in manufacturing, and Motion Control governs the movement of machinery, enhancing precision.

The advent of the Industrial Internet of Things (IIoT) and Industry 4.0 has ushered in an era of smart manufacturing, intertwining automated processes seamlessly. As we delve into this world, the fusion of technologies like SCARA robots and industrial sensors exemplifies the convergence of efficiency and innovation in the industrial landscape.

Within industrial automation, the landscape is further enriched by the integration of various technologies. Human-Machine Interface (HMI) plays a pivotal role in bridging the gap between operators and automated systems, offering a user-friendly interface for seamless interaction. The Manufacturing Execution System (MES) takes charge of coordinating and optimizing manufacturing processes, ensuring streamlined operations.

Distributed Control Systems (DCS) provide a distributed approach to control, enhancing efficiency and flexibility in large-scale industrial settings. The precision offered by PID control (Proportional-Integral-Derivative) mechanisms is crucial for maintaining desired parameters in industrial processes. Computer Numerical Control (CNC) systems, on the other hand, bring precision to machining processes, contributing to the intricacies of manufacturing.

Motion Control emerges as a key player, governing the movement of machinery with precision and accuracy. Industrial Robots, including SCARA robots, represent the forefront of automation, handling tasks with dexterity. The Industrial Internet of Things (IIoT) serves as a transformative force, connecting devices and systems for data-driven decision-making, and Industry 4.0 marks the era of intelligent, interconnected manufacturing.

In this landscape, smart manufacturing thrives, integrating technologies like industrial sensors to capture and relay critical data for informed decision-making. The synergy of these technologies illustrates the intricate dance between human expertise and automated precision in the industrial automation domain.

Temperature control

Temperature control is an important part of many industrial processes. It is used to ensure that products are manufactured correctly and to protect equipment from damage. Industrial temperature control systems are used in a wide variety of industries, including:

- Food and beverage: Industrial temperature control systems are used in the food and beverage industry to control the temperature of food and beverages during processing, packaging, and storage. This helps to ensure food safety and quality.

- Pharmaceuticals: Industrial temperature control systems are used in the pharmaceutical industry to control the temperature of pharmaceutical products during manufacturing, packaging, and storage. This helps to ensure product quality and efficacy.

- Chemicals: Industrial temperature control systems are used in the chemical industry to control the temperature of chemical reactions. This helps to ensure the safety and quality of the chemical products being produced.

- Electronics: Industrial temperature control systems are used in the electronics industry to control the temperature of electronic components during manufacturing and testing. This helps to prevent damage to the components and ensure product quality.

- Manufacturing: Industrial temperature control systems are used in a wide variety of manufacturing industries to control the temperature of products during processing. This helps to ensure product quality and consistency.

Industrial temperature control systems typically consist of three main components:

- Sensors: Sensors are used to measure the temperature of the product or process being controlled.

- Controllers: Controllers receive the temperature readings from the sensors and compare them to a set point. The controller then sends a signal to the actuators to adjust the temperature accordingly.

- Actuators: Actuators are used to adjust the temperature of the product or process being controlled. This can be done by using heaters, coolers, fans, or other devices.

Industrial temperature control systems can be very simple or very complex, depending on the needs of the application. Some systems are designed to control a single temperature point, while others can control multiple temperature points simultaneously. Some systems are also able to record and report temperature data, which can be used for quality control purposes.

Industrial temperature control systems are an important part of many industrial processes. They help to ensure product quality, safety, and consistency.

Pressure control

Pressure control is the process of maintaining a desired pressure in a system. It is used in a wide variety of industries, including:

- Food and beverage: Pressure control is used in the food and beverage industry to control the pressure of gases used in processing and packaging, such as carbon dioxide in soda and nitrogen in food packaging.

- Pharmaceuticals: Pressure control is used in the pharmaceutical industry to control the pressure of reactors and other equipment used in the manufacturing of drugs and other medications.

- Chemicals: Pressure control is used in the chemical industry to control the pressure of chemical reactions and other processes.

- Electronics: Pressure control is used in the electronics industry to control the pressure of chambers used in the manufacturing and testing of electronic components.

- Manufacturing: Pressure control is used in a wide variety of manufacturing industries to control the pressure of air and other gases used in production processes.

Industrial pressure control systems typically consist of three main components:

- Sensors: Sensors are used to measure the pressure of the system being controlled.

- Controllers: Controllers receive the pressure readings from the sensors and compare them to a set point. The controller then sends a signal to the actuators to adjust the pressure accordingly.

- Actuators: Actuators are used to adjust the pressure of the system being controlled. This can be done by using valves, pumps, or other devices.

Industrial pressure control systems can be very simple or very complex, depending on the needs of the application. Some systems are designed to control a single pressure point, while others can control multiple pressure points simultaneously. Some systems are also able to record and report pressure data, which can be used for quality control purposes.

Industrial pressure control systems are an important part of many industrial processes. They help to ensure product quality, safety, and consistency.

Here are some specific examples of industrial pressure control systems applications:

- Pressure relief valves: Pressure relief valves are used to protect equipment from damage caused by overpressure. They open automatically when the pressure in the system exceeds a certain point.

- Backpressure regulators: Backpressure regulators are used to maintain a constant pressure on the downstream side of a valve or other device. They are often used in applications where a precise pressure is required, such as in the manufacturing of pharmaceuticals.

- Pressure transducers: Pressure transducers are used to convert pressure readings into an electrical signal. This signal can be used to monitor the pressure in a system or to control a pressure control system.

Industrial pressure control systems play an important role in many industries. They help to ensure the safety, quality, and efficiency of industrial processes.

Flow control

Flow control is the process of regulating the rate of flow of a fluid or gas through a system. It is used in a wide variety of industries, including:

- Food and beverage: Flow control is used in the food and beverage industry to control the flow of liquids and gases during processing, packaging, and storage. This helps to ensure food safety and quality.

- Pharmaceuticals: Flow control is used in the pharmaceutical industry to control the flow of liquids and gases during manufacturing, packaging, and storage. This helps to ensure product quality and efficacy.

- Chemicals: Flow control is used in the chemical industry to control the flow of liquids and gases during chemical reactions and other processes. This helps to ensure the safety and quality of the chemical products being produced.

- Electronics: Flow control is used in the electronics industry to control the flow of liquids and gases during the manufacturing and testing of electronic components. This helps to prevent damage to the components and ensure product quality.

- Manufacturing: Flow control is used in a wide variety of manufacturing industries to control the flow of liquids and gases during processing. This helps to ensure product quality and consistency.

Industrial flow control systems typically consist of three main components:

- Sensors: Sensors are used to measure the flow rate of the fluid or gas being controlled.

- Controllers: Controllers receive the flow rate readings from the sensors and compare them to a set point. The controller then sends a signal to the actuators to adjust the flow rate accordingly.

- Actuators: Actuators are used to adjust the flow rate of the fluid or gas being controlled. This can be done by using valves, pumps, or other devices.

Industrial flow control systems can be very simple or very complex, depending on the needs of the application. Some systems are designed to control a single flow rate point, while others can control multiple flow rate points simultaneously. Some systems are also able to record and report flow rate data, which can be used for quality control purposes.

Industrial flow control systems are an important part of many industrial processes. They help to ensure product quality, safety, and consistency.

Here are some specific examples of industrial flow control systems applications:

- Control valves: Control valves are used to regulate the flow rate of fluids and gases in industrial systems. They come in a variety of types, such as butterfly valves, gate valves, and globe valves.

- Flow meters: Flow meters are used to measure the flow rate of fluids and gases in industrial systems. They come in a variety of types, such as orifice plates, turbine meters, and mass flow meters.

- Pumps: Pumps are used to increase the pressure of fluids and gases in industrial systems. They come in a variety of types, such as centrifugal pumps, positive displacement pumps, and jet pumps.

Industrial flow control systems play an important role in many industries. They help to ensure the safety, quality, and efficiency of industrial processes.

Industrial Automation Systems Applications

Industrial automation systems are used in a wide variety of industries to automate a variety of tasks. Some common applications include:

- Manufacturing: Industrial automation systems are used in manufacturing to automate tasks such as assembly, welding, painting, and inspection.

- Food and beverage: Industrial automation systems are used in the food and beverage industry to automate tasks such as packaging, bottling, and filling.

- Pharmaceuticals: Industrial automation systems are used in the pharmaceutical industry to automate tasks such as packaging, filling, and labeling.

- Automotive: Industrial automation systems are used in the automotive industry to automate tasks such as welding, painting, and assembly.

- Logistics: Industrial automation systems are used in the logistics industry to automate tasks such as picking, packing, and shipping.

Here are some specific examples of industrial automation systems applications:

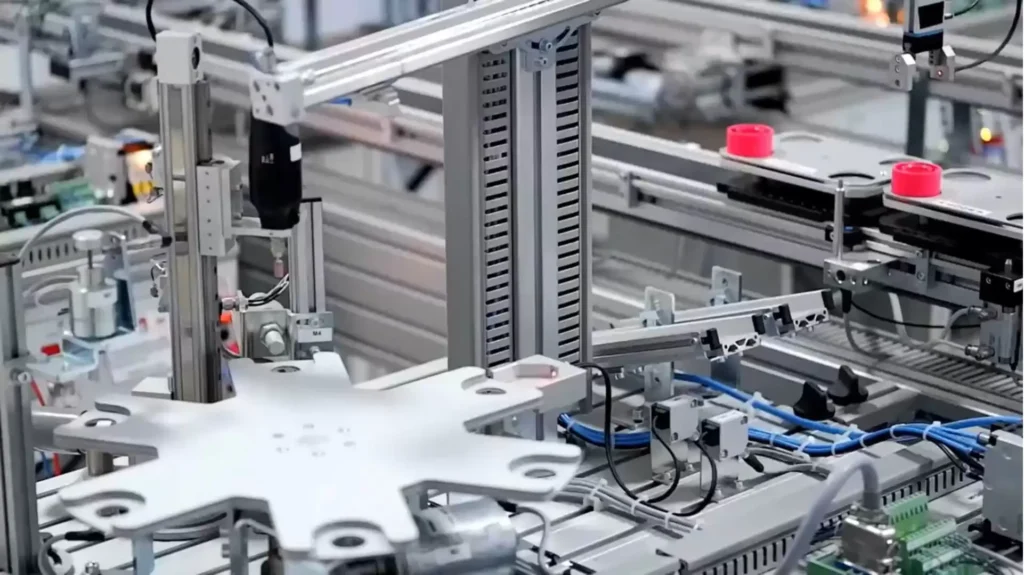

- Robotic assembly lines: Robotic assembly lines are used to assemble products such as cars, electronics, and appliances. Robots can perform a variety of tasks on the assembly line, such as welding, picking and placing parts, and inspecting products.

- Automated packaging lines: Automated packaging lines are used to package products such as food and beverages, pharmaceuticals, and consumer goods. These lines typically include a variety of machines, such as fillers, cappers, and labelers.

- Automated warehouses: Automated warehouses use robots and other automated systems to pick, pack, and ship products. This can help to improve efficiency and accuracy.

- Automated inspection systems: Automated inspection systems are used to inspect products for defects. This can help to improve product quality and reduce waste.

Industrial automation systems can offer a number of benefits, including:

- Increased productivity: Industrial automation systems can help to increase productivity by automating tasks that are repetitive, time-consuming, or dangerous.

- Improved quality: Industrial automation systems can help to improve product quality by reducing the risk of human error.

- Reduced costs: Industrial automation systems can help to reduce costs by reducing the need for manual labor and by improving efficiency.

- Increased safety: Industrial automation systems can help to improve safety by reducing the need for workers to interact with dangerous machinery.

Overall, industrial automation systems can help businesses to improve their productivity, quality, costs, and safety.

Robotic Assembly Lines

Robotic assembly lines are automated production lines that use robots to perform tasks such as picking and placing parts, assembling products, and inspecting finished products. Robotic assembly lines are used in a wide variety of industries, including automotive, electronics, food and beverage, and pharmaceuticals.

Robotic assembly lines offer a number of benefits over traditional manual assembly lines, including:

- Increased productivity: Robotic assembly lines can operate faster and more efficiently than manual assembly lines, resulting in increased productivity.

- Improved quality: Robotic assembly lines can help to improve product quality by reducing the risk of human error.

- Reduced costs: Robotic assembly lines can help to reduce costs by reducing the need for manual labor and improving efficiency.

- Increased safety: Robotic assembly lines can help to improve safety by reducing the need for workers to interact with dangerous machinery.

Robotic assembly lines can be customized to meet the specific needs of each manufacturer. For example, a robotic assembly line for assembling cars may be different from a robotic assembly line for assembling smartphones.

Here are some specific examples of robotic assembly line applications:

- Automotive assembly lines: Robotic assembly lines are widely used in the automotive industry to assemble cars, trucks, and other vehicles. Robots perform a variety of tasks on automotive assembly lines, such as welding body panels, painting car bodies, and installing engines and other components.

- Electronics assembly lines: Robotic assembly lines are also widely used in the electronics industry to assemble electronic devices such as smartphones, computers, and televisions. Robots perform a variety of tasks on electronics assembly lines, such as placing components on circuit boards, soldering components together, and testing finished products.

- Food and beverage assembly lines: Robotic assembly lines are also used in the food and beverage industry to package food and beverages. Robots perform a variety of tasks on food and beverage assembly lines, such as picking and placing food items in containers, filling containers with liquids, and sealing containers.

- Pharmaceutical assembly lines: Robotic assembly lines are also used in the pharmaceutical industry to package pharmaceuticals. Robots perform a variety of tasks on pharmaceutical assembly lines, such as picking and placing pharmaceutical products in containers, filling containers with pharmaceutical products, and sealing containers.

Overall, robotic assembly lines play an important role in many industries. They help manufacturers to improve their productivity, quality, costs, and safety.

Here are some trends in robotic assembly lines:

- Increased use of collaborative robots: Collaborative robots, also known as cobots, are robots that can work safely alongside human workers. Cobots are becoming increasingly popular in robotic assembly lines because they can be used to perform tasks that are difficult or dangerous for human workers.

- Greater integration: Robotic assembly lines are becoming increasingly integrated with other manufacturing systems, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This integration helps to improve the efficiency and accuracy of robotic assembly lines.

- More customization: Robotic assembly lines are being customized more and more to meet the specific needs of each manufacturer. This is especially important for manufacturers of niche or complex products.

Overall, the trend is towards more collaborative, integrated, and customized robotic assembly lines. This is helping manufacturers to improve their productivity, quality, costs, and safety.

Automated Packaging Lines

Automated packaging lines are used in a wide variety of industries to package products of all shapes and sizes. They can be used to package food and beverages, pharmaceuticals, consumer goods, and more.

Automated packaging lines offer a number of benefits over manual packaging lines, including:

- Increased productivity: Automated packaging lines can run faster and more efficiently than manual packaging lines, resulting in increased productivity.

- Improved quality: Automated packaging lines can help to improve product quality by reducing the risk of human error.

- Reduced costs: Automated packaging lines can help to reduce costs by reducing the need for manual labor and improving efficiency.

- Increased safety: Automated packaging lines can help to improve safety by reducing the need for workers to interact with dangerous machinery.

- Reduced environmental impact: Automated packaging lines can help to reduce environmental impact by reducing waste and energy consumption.

Automated packaging lines can be customized to meet the specific needs of each manufacturer. For example, an automated packaging line for food and beverages may be different from an automated packaging line for pharmaceuticals. Automated packaging lines can also be designed to accommodate a variety of packaging materials, such as plastic, glass, and cardboard.

Here are some specific examples of automated packaging line applications:

- Food and beverage packaging lines: Automated packaging lines are widely used in the food and beverage industry to package a wide variety of products, including bottled water, canned goods, snacks, and frozen foods. These lines typically include a number of machines, such as bottle washers, fillers, cappers, and labelers.

- Pharmaceutical packaging lines: Automated packaging lines are also widely used in the pharmaceutical industry to package a wide variety of products, including prescription drugs, over-the-counter medications, and medical supplies. These lines typically include a number of machines, such as blister feeders, product loaders, heat sealers, and labelers.

- Consumer goods packaging lines: Automated packaging lines are also widely used in the consumer goods industry to package a wide variety of products, such as personal care products, household goods, and electronics. These lines typically include a number of machines, such as carton erectors, product loaders, carton closers, and labelers.

Automated packaging lines play an important role in many industries. They help manufacturers to improve their productivity, quality, costs, safety, and environmental impact.

Here are some trends in automated packaging lines:

- Increased use of robotics: Robotics is being used more and more in automated packaging lines. Robots can perform a variety of tasks, such as picking and placing products, filling containers, and packing cartons.

- Greater integration: Automated packaging lines are becoming increasingly integrated with other manufacturing systems, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This integration helps to improve the efficiency and accuracy of automated packaging lines.

- More customization: Automated packaging lines are being customized more and more to meet the specific needs of each manufacturer. This is especially important for manufacturers of niche or complex products.

- Increased focus on sustainability: Manufacturers are becoming increasingly focused on sustainability, and this trend is also reflected in automated packaging lines. Manufacturers are looking for ways to reduce waste, energy consumption, and environmental impact.

Overall, the trend is towards more robotic, integrated, customized, and sustainable automated packaging lines. This is helping manufacturers to improve their productivity, quality, costs, safety, and environmental impact.

Automated Warehouses

Automated warehouses are warehouses that use technology to automate tasks such as picking, packing, and shipping products. Automated warehouses are becoming increasingly popular as businesses look for ways to improve efficiency and reduce costs.

There are a number of different types of automated warehouse systems, including:

- Automated storage and retrieval systems (AS/RS): AS/RS systems use robots and cranes to store and retrieve products from high-density shelving systems. AS/RS systems can be used to store a wide variety of products, including pallets, cases, and individual items.

- Goods-to-person (GTP) systems: GTP systems bring products to workers instead of requiring workers to walk to the products. This can be done using a variety of technologies, such as conveyors, carousels, and robots.

- Automated picking systems: Automated picking systems use robots and other technologies to pick products from shelves and place them in boxes or totes. Automated picking systems can be used to pick a wide variety of products, including individual items and cases.

- Automated packing systems: Automated packing systems use robots and other technologies to pack products into boxes or totes. Automated packing systems can be used to pack a wide variety of products, including individual items and cases.

- Automated shipping systems: Automated shipping systems use robots and other technologies to sort and ship products. Automated shipping systems can be used to ship a wide variety of products, including individual items and cases.

Automated warehouses offer a number of benefits over manual warehouses, including:

- Increased productivity: Automated warehouses can run faster and more efficiently than manual warehouses, resulting in increased productivity.

- Improved accuracy: Automated warehouses can help to improve accuracy by reducing the risk of human error.

- Reduced costs: Automated warehouses can help to reduce costs by reducing the need for manual labor and improving efficiency.

- Increased safety: Automated warehouses can help to improve safety by reducing the need for workers to interact with dangerous machinery.

- Improved inventory management: Automated warehouses can help to improve inventory management by providing real-time data on inventory levels and locations.

Automated warehouses are used in a wide variety of industries, including:

- Retail: Automated warehouses are widely used in the retail industry to store and ship products.

- E-commerce: Automated warehouses are also widely used in the e-commerce industry to store and ship products.

- Food and beverage: Automated warehouses are also used in the food and beverage industry to store and ship products.

- Pharmaceuticals: Automated warehouses are also used in the pharmaceutical industry to store and ship products.

- Manufacturing: Automated warehouses are also used in the manufacturing industry to store and ship products.

Overall, automated warehouses play an important role in many industries. They help businesses to improve their efficiency, accuracy, costs, safety, and inventory management.

Here are some trends in automated warehouses:

- Increased use of robotics: Robotics is being used more and more in automated warehouses. Robots can perform a variety of tasks, such as picking and placing products, packing boxes, and sorting products for shipping.

- Greater integration: Automated warehouses are becoming increasingly integrated with other business systems, such as enterprise resource planning (ERP) systems and customer relationship management (CRM) systems. This integration helps to improve the efficiency and accuracy of automated warehouses.

- More customization: Automated warehouses are being customized more and more to meet the specific needs of each business. This is especially important for businesses that sell a wide variety of products or that have complex shipping needs.

- Increased focus on sustainability: Businesses are becoming increasingly focused on sustainability, and this trend is also reflected in automated warehouses. Businesses are looking for ways to reduce waste, energy consumption, and environmental impact.

Overall, the trend is towards more robotic, integrated, customized, and sustainable automated warehouses. This is helping businesses to improve their efficiency, accuracy, costs, safety, inventory management, and sustainability.

Automated Inspection Systems

Automated inspection systems (AIS) are machines or software that use sensors, cameras, and other technologies to inspect products for defects. AIS are used in a wide variety of industries, including food and beverage, pharmaceuticals, manufacturing, and electronics.

AIS offer a number of benefits over manual inspection, including:

- Increased accuracy: AIS can detect defects that are too small or subtle for human eyes to see.

- Improved consistency: AIS can inspect products consistently and accurately, regardless of the inspector’s fatigue or experience level.

- Increased speed: AIS can inspect products much faster than humans can.

- Reduced costs: AIS can help to reduce costs by reducing the need for manual labor and by improving the quality of products.

There are a number of different types of AIS, including:

- Machine vision systems: Machine vision systems use cameras and software to inspect products for defects. Machine vision systems can be used to inspect a wide variety of products, including food and beverage products, pharmaceutical products, manufactured goods, and electronic components.

- X-ray inspection systems: X-ray inspection systems use X-rays to inspect products for internal defects. X-ray inspection systems are often used to inspect food and beverage products for foreign objects, such as metal or glass.

- Metal detection systems: Metal detection systems use magnets or other technologies to detect metal in products. Metal detection systems are often used to inspect food and beverage products for metal fragments.

AIS are an important part of many manufacturing and quality control processes. They help to ensure that products are free of defects and that they meet quality standards.

Here are some specific examples of AIS applications:

- Food and beverage inspection: AIS are used in the food and beverage industry to inspect products for defects such as foreign objects, contamination, and incorrect packaging.

- Pharmaceutical inspection: AIS are used in the pharmaceutical industry to inspect products for defects such as incorrect dosage, missing tablets, and broken packaging.

- Manufacturing inspection: AIS are used in the manufacturing industry to inspect products for defects such as cracks, dents, and incorrect dimensions.

- Electronics inspection: AIS are used in the electronics industry to inspect products for defects such as missing components, solder defects, and incorrect assembly.

Overall, AIS play an important role in many industries. They help manufacturers to ensure that their products are free of defects and that they meet quality standards.

Here are some trends in AIS:

- Increased use of artificial intelligence (AI): AI is being used more and more in AIS to improve their accuracy and reliability. AI can be used to train AIS to recognize and classify defects that would be difficult or impossible for humans to detect.

- Greater integration: AIS are becoming increasingly integrated with other manufacturing systems, such as production lines and quality control systems. This integration helps to improve the efficiency and accuracy of AIS.

- More customization: AIS are being customized more and more to meet the specific needs of each manufacturer. This is especially important for manufacturers of complex or niche products.

Overall, the trend is towards more AI-powered, integrated, and customized AIS. This is helping manufacturers to improve the quality of their products and to reduce costs.

EMS Automation Solutions

Introducing EMS Automation Solutions: Pioneering Excellence in Industrial Automation

At EMS Automation Solutions, we stand at the forefront of innovation, offering cutting-edge industrial automation solutions that redefine the way industries operate. With a relentless commitment to precision, efficiency, and reliability, we empower businesses to navigate the complexities of the modern industrial landscape seamlessly.

Comprehensive Industrial Automation Portfolio

Our extensive portfolio encompasses a diverse range of industrial automation solutions tailored to meet the unique needs of our clients. From PLC (Programmable Logic Controller) programming to SCADA (Supervisory Control and Data Acquisition) systems, robotics, and state-of-the-art control valves, we deliver holistic automation solutions that drive productivity and operational excellence.

PLC Programming Excellence

Unlock the full potential of your industrial processes with our unparalleled PLC programming expertise. Our skilled team of engineers crafts custom solutions that optimize control, enhance reliability, and streamline processes. From designing intricate control logic to seamless integration with other automation components, our PLC solutions are tailored to elevate your production capabilities.

SCADA Systems for Real-Time Control

Experience real-time control and monitoring like never before with our SCADA systems. EMS Automation Solutions leverages advanced SCADA technologies to provide a centralized platform for overseeing and managing diverse industrial processes. Gain insights, analyze data, and make informed decisions to propel your business into a new era of efficiency.

Robotics Redefined

Embrace the future of manufacturing with our state-of-the-art robotics solutions. From automated assembly lines to intricate tasks requiring precision, our robotics systems are engineered to enhance speed, accuracy, and safety in your operations. Collaborative robots, robotic arms, and automated guided vehicles – we bring a spectrum of robotics solutions to elevate your manufacturing prowess.

Control Valves for Precision Flow Management

Ensure optimal fluid flow control with our premium control valves. Whether it’s mitigating cavitation, addressing flashing issues, or managing noise levels, EMS Automation Solutions provides a comprehensive range of control valves designed for durability, efficiency, and precise control. Our valves are crafted to seamlessly integrate into your processes, offering reliability in every operation.

Global Reach, Local Expertise

With a global presence, EMS Automation Solutions combines international reach with local expertise. Our teams collaborate closely with clients to understand their unique challenges and deliver bespoke solutions. From conceptualization to implementation and ongoing support, we are your trusted partner throughout the automation journey.

Sustainable Automation Practices

EMS Automation Solutions is committed to sustainable automation practices. We incorporate energy-efficient technologies, promote waste reduction, and design automation solutions that align with eco-friendly principles. Join us in building a future where automation and sustainability go hand in hand.

Partner with EMS Automation Solutions for Tomorrow’s Automation Today

As industries evolve, so do we. EMS Automation Solutions is not just a provider of automation services – we are architects of innovation, architects of efficiency, and architects of your success. Partner with us to transform your industrial processes and embark on a journey towards unparalleled automation excellence. Elevate your operations with EMS Automation Solutions – where the future of automation begins today!