Artificial Intelligence (AI) is a branch of computer science that focuses on the development of intelligent machines capable of performing tasks that typically require human intelligence. These tasks include learning, reasoning, problem-solving, perception, understanding natural language, and interacting with the environment. AI aims to create systems that can mimic human cognitive functions and adapt to new situations and environments.

One of the key objectives of AI is to develop algorithms and models that enable machines to learn from data, recognize patterns, and make decisions autonomously. Machine learning, a subset of AI, plays a crucial role in achieving this objective by providing algorithms that allow computers to improve their performance on a task through experience.

There are various approaches to AI, including symbolic AI, which focuses on representing knowledge and reasoning about symbolic information using logic and rules, and connectionist AI, which is inspired by the structure and function of the human brain and utilizes artificial neural networks to learn from data.

Artificial Intelligence

AI has numerous applications across various industries and domains, including healthcare, finance, education, transportation, manufacturing, and entertainment. In healthcare, AI is used for medical imaging analysis, drug discovery, personalized treatment planning, and patient monitoring. In finance, AI algorithms are employed for fraud detection, algorithmic trading, credit scoring, and risk assessment. In education, AI systems assist in personalized learning, adaptive tutoring, and educational content creation. In transportation, AI powers autonomous vehicles, traffic management systems, and predictive maintenance for transportation infrastructure. In manufacturing, AI enables predictive maintenance, quality control, supply chain optimization, and robotic automation.

However, the development and deployment of AI also raise ethical, societal, and economic concerns, including job displacement due to automation, biases in AI algorithms, privacy issues related to data collection and surveillance, and the potential for AI to be used for malicious purposes. Addressing these challenges requires careful consideration of ethical principles, regulatory frameworks, and responsible AI practices to ensure that AI technologies benefit society while minimizing risks and unintended consequences.

Edge Computing

Edge computing refers to a distributed computing paradigm that brings computation and data storage closer to the location where it is needed, rather than relying solely on centralized data centers or cloud infrastructure. In edge computing, computation and data processing tasks are performed at or near the edge of the network, closer to the source of data generation, rather than relying on remote servers or data centers.

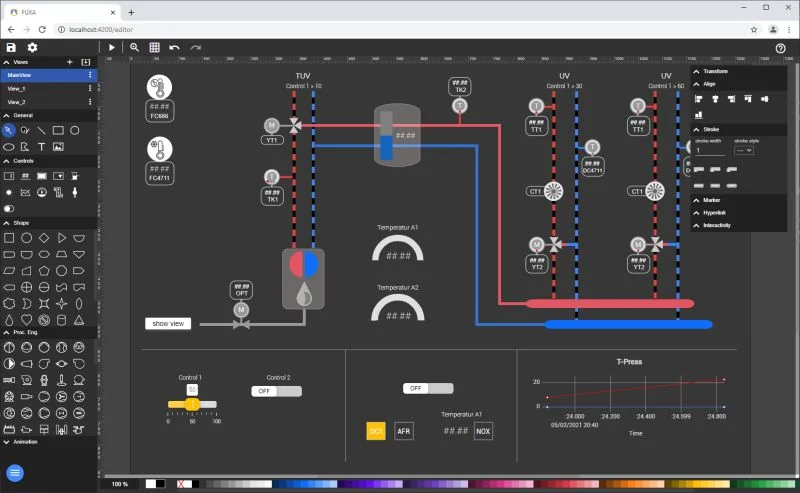

One of the key motivations behind edge computing is to reduce latency and improve response times for applications and services that require real-time or low-latency interactions. By processing data closer to where it is generated, edge computing can minimize the time it takes for data to travel over the network and back, enabling faster and more responsive applications. This is particularly important for applications such as IoT, autonomous vehicles, augmented reality, and industrial automation, which require real-time processing of sensor data and rapid decision-making.

Edge computing infrastructure typically consists of edge devices, edge servers, and edge gateways deployed at the network edge, such as IoT devices, routers, switches, and base stations. These edge devices are equipped with computing resources, storage capacity, and networking capabilities to perform computation and data processing tasks locally, without relying on centralized data centers or cloud servers.

Edge computing enables a wide range of applications and use cases across various industries and domains, including:

- IoT and Smart Devices: Edge computing is widely used in IoT deployments to process sensor data, monitor devices, and perform analytics at the edge of the network. By processing data locally on IoT devices or gateways, edge computing can reduce bandwidth usage, improve reliability, and enhance privacy and security for IoT applications.

- Autonomous Vehicles: Edge computing is essential for autonomous vehicles to process sensor data, make real-time decisions, and communicate with other vehicles and infrastructure. By deploying edge computing infrastructure at the network edge, autonomous vehicles can minimize latency and ensure rapid response times for critical tasks such as object detection, path planning, and collision avoidance.

- Augmented Reality and Virtual Reality: Edge computing is used in augmented reality (AR) and virtual reality (VR) applications to offload computation-intensive tasks such as rendering, image processing, and object recognition to edge servers or devices. By processing data locally at the edge, AR and VR applications can reduce latency and deliver more immersive and responsive user experiences.

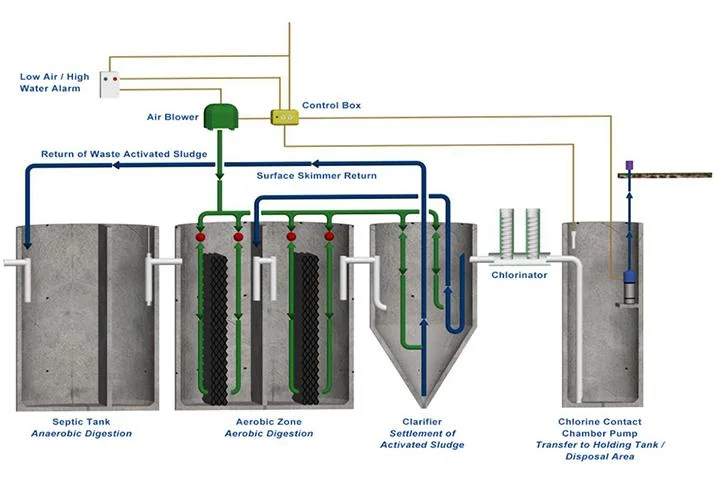

- Industrial Automation: Edge computing is widely used in industrial automation and manufacturing to monitor equipment, collect sensor data, and optimize production processes in real-time. By deploying edge computing infrastructure on factory floors or at remote sites, industrial organizations can improve operational efficiency, reduce downtime, and enable predictive maintenance.

- Telecommunications: Edge computing is increasingly being adopted by telecommunications providers to deploy services such as content delivery, video streaming, and network optimization at the network edge. By caching content and processing data closer to end-users, edge computing can reduce congestion, improve quality of service, and enhance user experience for mobile and broadband networks.

Overall, edge computing offers numerous benefits, including reduced latency, improved reliability, enhanced privacy and security, and greater scalability for distributed applications and services. As the adoption of IoT, autonomous systems, and real-time applications continues to grow, edge computing is expected to play an increasingly important role in enabling the next generation of connected devices and services. However, challenges such as resource constraints, network connectivity, data management, and security remain areas of active research and development in edge computing, requiring innovative solutions and standards to address.

Robotics

Robotics is a multidisciplinary field that involves the design, construction, operation, and use of robots to perform tasks autonomously or with human supervision. Robots are programmable machines that can sense, process, and act upon information from their environment to accomplish specific goals or objectives. Robotics draws upon concepts and techniques from various disciplines, including mechanical engineering, electrical engineering, computer science, artificial intelligence, and control theory, to develop robots that can perceive, interact with, and manipulate the physical world.

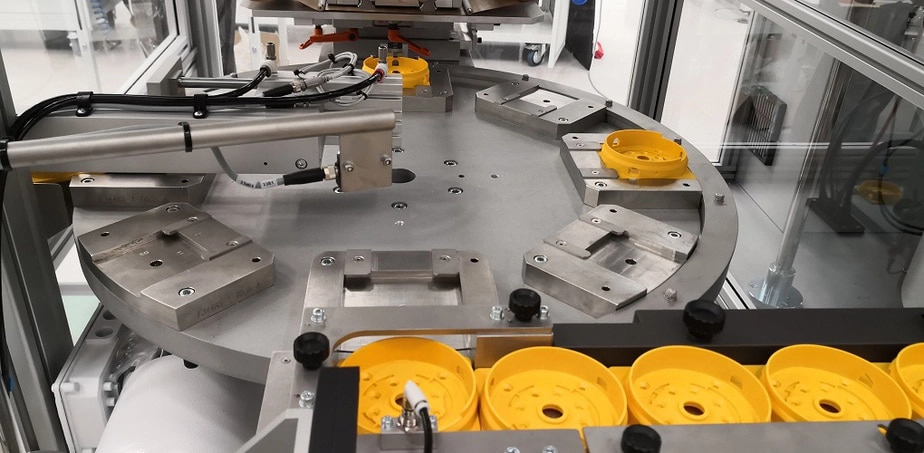

One of the key goals of robotics is to create machines that can perform tasks more efficiently, accurately, and safely than humans in a wide range of environments and applications. Robots can be designed to perform repetitive, dangerous, or tedious tasks in manufacturing, construction, healthcare, exploration, defense, agriculture, and other domains, thereby improving productivity, quality, and safety for human workers.

Robots can be classified into several types based on their design, capabilities, and applications:

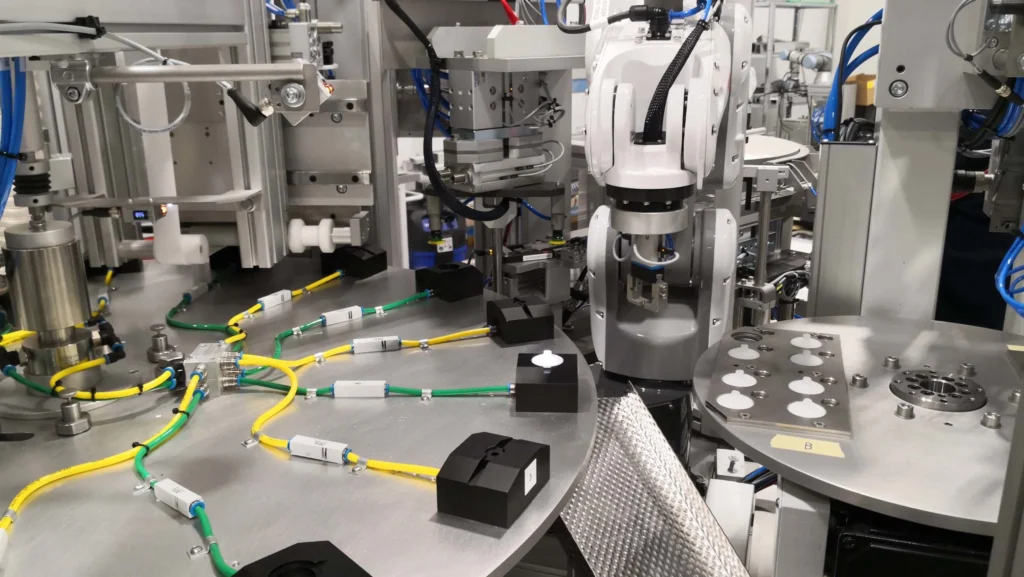

- Industrial Robots: Industrial robots are designed for manufacturing and assembly applications, such as welding, painting, pick-and-place, and packaging. These robots are typically used in factory settings to automate repetitive tasks and improve production efficiency, accuracy, and speed. Industrial robots are characterized by their precision, speed, and payload capacity, and are often equipped with sensors, actuators, and controllers for precise control and operation.

- Service Robots: Service robots are designed to interact with humans and perform tasks in non-industrial environments, such as homes, hospitals, offices, and public spaces. These robots are used for a wide range of applications, including cleaning, surveillance, delivery, entertainment, and assistance. Service robots are characterized by their mobility, flexibility, and adaptability to dynamic and unstructured environments, and are often equipped with sensors, cameras, and communication interfaces for interaction with humans.

- Mobile Robots: Mobile robots are designed to move autonomously or semi-autonomously in indoor or outdoor environments to perform navigation, exploration, and transportation tasks. These robots can be wheeled, legged, or aerial, depending on the terrain and application requirements. Mobile robots are used for applications such as warehouse automation, logistics, search and rescue, agriculture, and surveillance. Mobile robots are characterized by their mobility, agility, and robustness to navigate and operate in complex and dynamic environments.

- Humanoid Robots: Humanoid robots are designed to resemble and mimic human anatomy and behavior to perform tasks in human-like environments. These robots are used for applications such as social interaction, entertainment, education, and research. Humanoid robots are characterized by their anthropomorphic design, dexterity, and ability to interact with humans using natural language, gestures, and facial expressions.

- Medical Robots: Medical robots are designed for healthcare applications, such as surgery, diagnosis, rehabilitation, and assistance. These robots can perform precise and minimally invasive procedures, such as robotic surgery, teleoperation, and rehabilitation therapy, to improve patient outcomes and quality of care. Medical robots are characterized by their precision, dexterity, and ability to work in confined spaces within the human body.

Overall, robotics offers numerous benefits, including increased productivity, efficiency, safety, and quality of life for humans. As robotics technology continues to advance, robots are expected to play an increasingly important role in various aspects of society, including manufacturing, healthcare, transportation, entertainment, and exploration. However, challenges such as cost, complexity, ethics, and societal acceptance remain areas of active research and development in robotics, requiring interdisciplinary collaboration and responsible innovation to address.

Reinforcement Learning

Reinforcement learning (RL) is a type of machine learning paradigm that involves training agents to make sequential decisions by interacting with an environment to maximize cumulative rewards. Unlike supervised learning, where the agent learns from labeled examples, or unsupervised learning, where the agent learns patterns in unlabeled data, reinforcement learning is based on trial-and-error learning, where the agent learns from feedback received from the environment.

In reinforcement learning, an agent interacts with an environment by taking actions, receiving feedback in the form of rewards or penalties, and updating its policy or strategy to maximize the expected cumulative reward over time. The goal of reinforcement learning is to learn a policy that maps states of the environment to actions, such that the agent can make optimal decisions to achieve its objectives.

One of the key components of reinforcement learning is the reward signal, which provides feedback to the agent about the desirability of its actions. Rewards can be positive, negative, or zero, depending on whether the action taken by the agent leads to a desirable outcome, an undesirable outcome, or has no impact on the overall objective. The agent’s goal is to learn a policy that maximizes the expected cumulative reward over time, often by using techniques such as value iteration, policy iteration, or deep reinforcement learning.

Reinforcement learning algorithms can be broadly categorized into several types, including:

- Value-Based Methods: Value-based methods involve estimating the value or utility of different states or state-action pairs in the environment and selecting actions that maximize the expected cumulative reward. Examples of value-based methods include Q-learning, SARSA, and deep Q-networks (DQN), which learn value functions to approximate the optimal policy.

- Policy-Based Methods: Policy-based methods involve directly parameterizing the agent’s policy or strategy and optimizing it to maximize the expected cumulative reward. Examples of policy-based methods include policy gradients, actor-critic methods, and reinforcement learning with learned policies (REINFORCE), which learn to improve the policy through gradient ascent on the expected cumulative reward.

- Model-Based Methods: Model-based methods involve learning a model of the environment dynamics, such as transition probabilities and rewards, and using it to plan or simulate future trajectories to make decisions. Examples of model-based methods include Monte Carlo tree search (MCTS), dynamic programming, and model-based reinforcement learning algorithms, which learn to simulate the environment and search for optimal policies or value functions.

Reinforcement learning has numerous applications across various domains, including robotics, autonomous systems, game playing, recommendation systems, and control systems. In robotics and autonomous systems, reinforcement learning is used to train agents to perform tasks such as navigation, manipulation, and control in dynamic and uncertain environments. In game playing, reinforcement learning is used to train agents to play games such as chess, Go, and video games at human or superhuman levels. In recommendation systems, reinforcement learning is used to optimize personalized recommendations and maximize user engagement and satisfaction. In control systems, reinforcement learning is used to optimize control policies for complex and nonlinear systems, such as autonomous vehicles, industrial processes, and energy management systems.

As reinforcement learning continues to advance, it holds great promise for enabling agents to learn complex tasks and make intelligent decisions in real-world environments. With advancements in algorithms, models, and computational resources, reinforcement learning systems are becoming increasingly capable, scalable, and applicable to a wide range of domains and applications. However, challenges such as sample efficiency, exploration-exploitation trade-offs, and safety and reliability remain areas of active research and development in reinforcement learning, requiring interdisciplinary collaboration and responsible innovation to address.

Computer vision

Computer vision is a field of artificial intelligence and computer science that focuses on enabling computers to interpret and understand visual information from the real world, such as images and videos. The goal of computer vision is to develop algorithms and systems that can replicate human visual perception, enabling computers to analyze, recognize, and interpret visual data to extract meaningful information and make decisions.

One of the key challenges in computer vision is the interpretation of visual data, which is inherently complex and variable due to factors such as lighting conditions, viewpoint variations, occlusions, and object deformations. Computer vision algorithms use techniques from image processing, pattern recognition, machine learning, and deep learning to process and analyze visual data, extract relevant features, and make inferences about the content and context of the images.

Computer vision tasks can be broadly categorized into several areas, including:

- Image Classification: Image classification involves categorizing images into predefined classes or categories based on their visual content. This task is typically performed using supervised learning algorithms, such as convolutional neural networks (CNNs), which learn to map images to their corresponding labels or classes based on training data.

- Object Detection: Object detection involves identifying and localizing objects of interest within images or videos and drawing bounding boxes around them. This task is typically performed using algorithms such as region-based convolutional neural networks (R-CNNs), You Only Look Once (YOLO), and Single Shot Multibox Detector (SSD), which learn to detect objects and their spatial locations within images.

- Semantic Segmentation: Semantic segmentation involves partitioning images into semantically meaningful regions and assigning each pixel to a specific class or category. This task is typically performed using algorithms such as fully convolutional networks (FCNs), U-Net, and Mask R-CNN, which learn to classify each pixel in an image based on its visual appearance and context.

- Object Tracking: Object tracking involves following the movement and trajectory of objects across consecutive frames in a video sequence. This task is typically performed using algorithms such as Kalman filters, optical flow, and deep learning-based trackers, which learn to predict the motion and location of objects over time.

- Scene Understanding: Scene understanding involves analyzing the spatial relationships and semantic context of objects within images or videos to infer higher-level concepts such as scene categories, object interactions, and human activities. This task is typically performed using algorithms such as scene graph generation, action recognition, and visual question answering (VQA), which learn to understand the content and context of visual scenes.

Computer vision has numerous applications across various industries and domains, including healthcare, automotive, retail, surveillance, entertainment, and augmented reality. In healthcare, computer vision is used for medical imaging analysis, disease diagnosis, surgical navigation, and telemedicine by analyzing medical images and videos to assist healthcare professionals in diagnosis and treatment planning. In automotive, computer vision is used for autonomous driving, driver assistance systems, and traffic surveillance by analyzing sensor data from cameras, LiDAR, and radar to detect objects, pedestrians, and road signs. In retail, computer vision is used for product recognition, inventory management, and cashierless checkout systems by analyzing images and videos of products and customers to streamline operations and enhance the shopping experience. In surveillance, computer vision is used for security monitoring, crowd analysis, and anomaly detection by analyzing video streams to detect suspicious activities and events in real-time. In entertainment, computer vision is used for virtual reality, motion capture, and facial recognition by analyzing images and videos to create immersive experiences and interact with virtual environments.

As computer vision continues to advance, it holds great promise for enabling machines to perceive and understand visual information in a manner similar to humans. With advancements in algorithms, models, and computational resources, computer vision systems are becoming increasingly accurate, efficient, and applicable to a wide range of domains and applications. However, challenges such as occlusions, viewpoint variations, lighting conditions, and privacy concerns remain areas of active research and development in computer vision, requiring interdisciplinary collaboration and responsible innovation to address.

Natural Language Processing (NLP)

Natural Language Processing (NLP) is a branch of artificial intelligence and computational linguistics that focuses on enabling computers to understand, interpret, and generate human language in a manner that is both natural and meaningful. NLP encompasses a wide range of tasks and techniques for processing and analyzing text data, such as written documents, emails, social media posts, and spoken conversations.

One of the key challenges in NLP is the ambiguity and complexity of natural language, which can include variations in grammar, syntax, semantics, and pragmatics. NLP algorithms and models use techniques from linguistics, machine learning, and deep learning to extract linguistic features, model language structure, and infer meaning from textual data.

NLP tasks can be broadly categorized into several areas, including:

- Text Classification: Text classification involves categorizing text documents into predefined classes or categories based on their content. This task is typically performed using supervised learning algorithms, such as support vector machines (SVM), Naive Bayes, and deep neural networks, which learn to classify documents based on features extracted from the text.

- Named Entity Recognition (NER): Named Entity Recognition involves identifying and extracting named entities such as persons, organizations, locations, dates, and numerical expressions from text documents. This task is typically performed using sequence labeling algorithms, such as conditional random fields (CRF) and recurrent neural networks (RNNs), which learn to tag words or phrases with their corresponding entity types.

- Sentiment Analysis: Sentiment Analysis involves analyzing the sentiment or emotion expressed in text documents, such as positive, negative, or neutral sentiments. This task is typically performed using machine learning algorithms, such as logistic regression, support vector machines (SVM), and recurrent neural networks (RNNs), which learn to classify text documents based on the sentiment expressed in the text.

- Text Generation: Text Generation involves generating coherent and contextually relevant text based on a given prompt or input. This task is typically performed using generative models, such as recurrent neural networks (RNNs), long short-term memory (LSTM) networks, and transformers, which learn to generate text by modeling the probability distribution of words or tokens in a corpus of text.

- Machine Translation: Machine Translation involves automatically translating text from one language to another. This task is typically performed using statistical machine translation (SMT) or neural machine translation (NMT) models, which learn to map sequences of words or tokens from one language to another based on parallel corpora of translated text.

- Question Answering: Question Answering involves automatically answering questions posed in natural language based on a given context or knowledge base. This task is typically performed using machine reading comprehension (MRC) models, such as transformers and BERT (Bidirectional Encoder Representations from Transformers), which learn to extract relevant information from text documents to generate accurate answers to questions.

NLP has numerous applications and use cases across various domains and industries, including:

- Information Retrieval and Search: NLP is used in search engines to understand user queries and retrieve relevant documents or web pages based on the query content and context. NLP techniques such as keyword extraction, document summarization, and relevance ranking are used to improve search results and user experience.

- Virtual Assistants and Chatbots: NLP is used in virtual assistants and chatbots to understand user queries and respond with relevant information or actions. NLP techniques such as intent recognition, entity extraction, and dialogue management are used to enable natural and conversational interactions between users and virtual assistants.

- Text Analytics and Business Intelligence: NLP is used in text analytics and business intelligence to analyze large volumes of text data, such as customer reviews, social media posts, and news articles, to extract insights and trends. NLP techniques such as sentiment analysis, topic modeling, and named entity recognition are used to identify patterns and sentiment in textual data.

- Document Summarization and Information Extraction: NLP is used in document summarization and information extraction to automatically summarize and extract key information from text documents, such as news articles, research papers, and legal documents. NLP techniques such as text summarization, entity extraction, and event detection are used to distill and condense large volumes of textual data into concise summaries or structured information.

- Language Translation and Localization: NLP is used in language translation and localization to automatically translate text from one language to another and adapt it to the cultural and linguistic norms of the target audience. NLP techniques such as machine translation, language modeling, and cross-lingual embeddings are used to bridge language barriers and enable communication across different linguistic communities.

Overall, NLP offers numerous benefits, including improved communication, productivity, and decision-making across various domains and industries. As NLP continues to advance, it holds great promise for enabling machines to understand and interact with human language in more natural and meaningful ways. However, challenges such as ambiguity, context dependence, and cultural nuances remain areas of active research and development in NLP, requiring interdisciplinary collaboration and responsible innovation to address.

Autonomous Vehicles

Autonomous vehicles, also known as self-driving cars or driverless vehicles, are vehicles capable of sensing, perceiving, and navigating the environment without human intervention. The development of autonomous vehicles is a significant technological advancement that integrates various disciplines such as robotics, computer vision, artificial intelligence, and automotive engineering to create vehicles capable of operating safely and efficiently on public roads.

Autonomous vehicles rely on a combination of sensors, actuators, and onboard computing systems to perceive the environment, plan safe trajectories, and control vehicle motion. Some of the key components and technologies used in autonomous vehicles include:

- Sensors: Autonomous vehicles are equipped with a variety of sensors to perceive the surrounding environment, including LiDAR (Light Detection and Ranging), radar, cameras, ultrasonic sensors, and GPS (Global Positioning System). These sensors provide information about the vehicle’s surroundings, including other vehicles, pedestrians, road signs, lane markings, and obstacles.

- Perception Algorithms: Perception algorithms process data from sensors to detect and recognize objects in the environment, such as vehicles, pedestrians, cyclists, and obstacles. Computer vision techniques, such as object detection, tracking, and segmentation, are used to interpret sensor data and identify relevant objects and their spatial relationships.

- Localization and Mapping: Autonomous vehicles use localization and mapping algorithms to determine their position and orientation relative to the surrounding environment. Techniques such as SLAM (Simultaneous Localization and Mapping) combine sensor data with prior knowledge of the environment to create and update a map of the vehicle’s surroundings and estimate its pose in real-time.

- Path Planning and Decision-Making: Autonomous vehicles use path planning and decision-making algorithms to generate safe and efficient trajectories through the environment. These algorithms consider factors such as traffic laws, road conditions, vehicle dynamics, and other agents’ behaviors to plan trajectories that minimize risk and achieve the vehicle’s objectives, such as reaching a destination or avoiding collisions.

- Control Systems: Control systems in autonomous vehicles are responsible for executing planned trajectories by adjusting vehicle dynamics, such as steering, acceleration, and braking, to follow desired paths and respond to changing conditions. These systems use feedback control techniques to regulate vehicle motion and maintain stability and safety during operation.

Autonomous vehicles can be classified into several levels of autonomy based on the extent of human intervention required:

- Level 0: The vehicle has no automation, and all driving tasks are performed by the human driver.

- Level 1: The vehicle has driver assistance features, such as adaptive cruise control or lane-keeping assistance, but the human driver is responsible for monitoring the environment and controlling the vehicle.

- Level 2: The vehicle has partial automation and can perform some driving tasks, such as steering, acceleration, and braking, under certain conditions. However, the human driver must remain engaged and ready to take over control when necessary.

- Level 3: The vehicle has conditional automation and can perform most driving tasks autonomously under specific conditions or environments, such as highway driving. The human driver is still required to be available to intervene if needed but can disengage from driving tasks.

- Level 4: The vehicle has high automation and can perform all driving tasks autonomously within certain operational domains or environments, such as urban or suburban areas. The human driver may not need to be actively involved in driving but must be prepared to take over control if requested by the vehicle.

- Level 5: The vehicle has full automation and can perform all driving tasks autonomously under any conditions or environments without human intervention. The vehicle is capable of operating as a driverless vehicle in all scenarios and does not require human supervision.

Autonomous vehicles have numerous potential benefits, including:

- Safety: Autonomous vehicles have the potential to reduce the number of traffic accidents and fatalities by eliminating human errors, such as distracted driving, speeding, and impaired driving.

- Efficiency: Autonomous vehicles can improve traffic flow and reduce congestion by optimizing vehicle spacing, speed, and routing. They can also reduce fuel consumption and emissions by driving more efficiently and smoothly.

- Accessibility: Autonomous vehicles have the potential to increase mobility and accessibility for people who are unable to drive, such as the elderly, disabled, or visually impaired, by providing a safe and convenient transportation option.

- Productivity: Autonomous vehicles can enable passengers to use travel time more productively for work, leisure, or relaxation, without the need for active supervision of the driving task.

- Urban Planning: Autonomous vehicles can influence urban planning and design by reducing the need for parking spaces, improving land use efficiency, and promoting alternative modes of transportation, such as ride-sharing and public transit.

Despite these potential benefits, the widespread adoption of autonomous vehicles faces several challenges and considerations, including:

- Technical Challenges: Autonomous vehicles must overcome technical challenges related to perception, decision-making, control, and reliability to ensure safe and efficient operation in diverse and dynamic environments.

- Regulatory and Legal Frameworks: The deployment of autonomous vehicles requires the development of regulatory and legal frameworks to address liability, insurance, licensing, and safety standards.

- Ethical Considerations: Autonomous vehicles raise ethical considerations related to decision-making in critical situations, such as moral dilemmas and trade-offs between different stakeholders’ interests.

- Security and Privacy: Autonomous vehicles must address security and privacy concerns related to cybersecurity threats, data breaches, and unauthorized access to vehicle systems and personal information.

- Social Acceptance: The acceptance and adoption of autonomous vehicles depend on public perception, trust, and confidence in the technology’s safety, reliability, and benefits.

Overall, autonomous vehicles represent a transformative technology with the potential to revolutionize transportation and mobility, leading to safer, more efficient, and more sustainable transportation systems. However, realizing this vision requires collaboration and coordination among stakeholders, including policymakers, regulators, industry stakeholders, researchers, and the general public, to address technical, regulatory, ethical, and social challenges and ensure the responsible development and deployment of autonomous vehicles.

Internet of Things (IoT)

The Internet of Things (IoT) refers to the network of interconnected devices, sensors, and objects embedded with technology that enables them to collect, exchange, and act on data without human intervention. IoT devices can range from consumer electronics, such as smart thermostats and wearable fitness trackers, to industrial equipment, such as connected machinery and smart sensors in manufacturing plants. The proliferation of IoT devices has led to the creation of vast networks of interconnected devices that generate and exchange massive amounts of data, enabling new applications and services across various industries and domains.

IoT devices typically consist of sensors or actuators that collect data from the physical environment, such as temperature, humidity, motion, and location, and transmit this data over the internet to centralized or distributed computing systems for processing and analysis. These systems can then generate insights, trigger actions, or provide feedback based on the data received from IoT devices, enabling real-time monitoring, control, and automation of physical processes and systems.

The Internet of Things has numerous applications and use cases across various industries and domains, including:

- Smart Home: In the smart home market, IoT devices such as smart thermostats, lighting systems, security cameras, and voice-activated assistants enable homeowners to monitor and control their home environment remotely, improve energy efficiency, and enhance security and convenience.

- Smart Cities: In smart city initiatives, IoT technologies are used to deploy connected infrastructure and services, such as smart streetlights, traffic management systems, waste management solutions, and public transportation systems, to improve urban mobility, sustainability, and quality of life for residents.

- Industrial IoT (IIoT): In industrial settings, IoT devices and sensors are used to monitor and optimize manufacturing processes, track inventory and assets, perform predictive maintenance, and improve operational efficiency and productivity in sectors such as manufacturing, logistics, and utilities.

- Healthcare: In healthcare, IoT devices such as wearable health monitors, remote patient monitoring systems, and medical sensors enable healthcare providers to monitor patient health remotely, deliver personalized care, and improve patient outcomes through early detection and intervention.

- Agriculture: In agriculture, IoT technologies are used to deploy precision agriculture solutions, such as soil moisture sensors, weather monitoring systems, and automated irrigation systems, to optimize crop yields, conserve water resources, and enhance sustainability in farming practices.

- Transportation and Logistics: In transportation and logistics, IoT devices such as GPS trackers, telematics systems, and connected vehicles enable real-time tracking and monitoring of shipments, optimize route planning and delivery scheduling, and improve supply chain visibility and efficiency.

- Retail: In retail, IoT technologies are used to deploy smart shelves, inventory management systems, and beacon technology to track product inventory, analyze customer behavior, and deliver personalized shopping experiences in brick-and-mortar stores and online channels.

Despite its numerous benefits and applications, the Internet of Things also poses several challenges and risks, including:

- Security and Privacy: IoT devices are often vulnerable to security breaches, hacking, and data breaches due to their interconnected nature and the proliferation of unsecured devices. Security vulnerabilities in IoT devices can expose sensitive data, compromise user privacy, and create entry points for cyber attacks and malware infections.

- Interoperability and Standards: The lack of interoperability and standardized protocols among IoT devices and platforms can hinder integration, interoperability, and scalability, limiting the ability to deploy and manage heterogeneous IoT ecosystems effectively.

- Data Management and Analytics: The massive volumes of data generated by IoT devices pose challenges for data management, storage, processing, and analysis. Effective data analytics and insights require robust data governance, data integration, and analytics capabilities to extract actionable insights and value from IoT data.

- Reliability and Resilience: IoT devices and networks must be reliable and resilient to disruptions, failures, and cyber attacks to ensure continuous operation and availability of critical services. Redundancy, failover mechanisms, and disaster recovery plans are essential to mitigate the impact of outages and disruptions in IoT deployments.

- Regulatory Compliance: IoT deployments must comply with regulatory requirements and standards for data protection, privacy, security, and safety in various jurisdictions and industries. Compliance with regulations such as the General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA) is essential to protect user privacy and mitigate legal and regulatory risks associated with IoT deployments.

To address these challenges and realize the full potential of the Internet of Things, stakeholders must collaborate to develop and adopt best practices, standards, and technologies for securing IoT deployments, managing IoT data, and ensuring interoperability, reliability, and privacy in IoT ecosystems. Additionally, ongoing research and innovation in areas such as edge computing, artificial intelligence, and blockchain can further enhance the capabilities and applications of the Internet of Things, driving continued growth and innovation in the IoT market.

Machine Learning

Machine learning is a branch of artificial intelligence (AI) that focuses on developing algorithms and statistical models that enable computers to learn from and make predictions or decisions based on data without being explicitly programmed. Machine learning algorithms learn patterns and relationships from labeled or unlabeled data through a process of iterative training, where they adjust their parameters or weights to minimize errors and improve performance on a given task.

Machine learning algorithms can be categorized into several types, including:

- Supervised Learning: In supervised learning, algorithms are trained on labeled data, where each input is associated with a corresponding output or target variable. Supervised learning algorithms learn to map input data to output labels by minimizing the difference between predicted and actual outputs, such as regression for continuous variables or classification for discrete labels.

- Unsupervised Learning: In unsupervised learning, algorithms are trained on unlabeled data, where the objective is to discover patterns, structures, or relationships in the data without explicit guidance or supervision. Unsupervised learning algorithms include clustering algorithms, such as k-means clustering and hierarchical clustering, which group similar data points together based on their attributes.

- Semi-supervised Learning: Semi-supervised learning combines elements of supervised and unsupervised learning by using a small amount of labeled data and a larger amount of unlabeled data for training. Semi-supervised learning algorithms leverage the labeled data to guide the learning process and improve performance on tasks such as classification or regression.

- Reinforcement Learning: Reinforcement learning involves training agents to interact with an environment and learn optimal behavior through trial and error. Reinforcement learning algorithms learn to maximize cumulative rewards by taking actions that lead to favorable outcomes and receiving feedback from the environment in the form of rewards or penalties.

Machine learning algorithms are used in a wide range of applications and domains, including:

- Natural Language Processing (NLP): In natural language processing, machine learning algorithms are used to analyze and understand human language, including tasks such as text classification, sentiment analysis, machine translation, and speech recognition.

- Computer Vision: In computer vision, machine learning algorithms are used to interpret and analyze visual data, including tasks such as object detection, image classification, image segmentation, and facial recognition.

- Predictive Analytics: In predictive analytics, machine learning algorithms are used to analyze historical data and make predictions or forecasts about future events or trends, such as sales forecasting, demand prediction, risk assessment, and fraud detection.

- Recommendation Systems: In recommendation systems, machine learning algorithms are used to analyze user preferences and behavior and make personalized recommendations for products, services, or content, such as movie recommendations, music playlists, and e-commerce product suggestions.

- Healthcare: In healthcare, machine learning algorithms are used for tasks such as disease diagnosis, medical image analysis, patient monitoring, and drug discovery, where they can analyze large volumes of medical data and assist healthcare professionals in decision-making.

- Finance: In finance, machine learning algorithms are used for tasks such as algorithmic trading, credit scoring, risk management, and fraud detection, where they can analyze financial data and market trends to make informed decisions and mitigate risks.

- Autonomous Vehicles: In autonomous vehicles, machine learning algorithms are used for tasks such as object detection, path planning, and decision-making, where they can analyze sensor data and navigate complex environments safely and efficiently.

Machine learning continues to advance rapidly, driven by developments in algorithms, computing infrastructure, and data availability. Recent trends in machine learning include deep learning, which uses neural networks with multiple layers to learn complex representations from data, and transfer learning, which leverages knowledge from pre-trained models to improve performance on related tasks. As machine learning continues to evolve, it holds great promise for revolutionizing various industries and domains, enabling new capabilities, insights, and applications that were previously unimaginable. However, machine learning also raises ethical, social, and privacy concerns, such as algorithmic bias, data privacy, and accountability, which must be addressed to ensure responsible and ethical use of machine learning technologies.

Artificial Neural Networks

Artificial Neural Networks (ANNs) are computational models inspired by the structure and function of biological neural networks in the human brain. ANNs consist of interconnected nodes, or artificial neurons, organized into layers and trained to perform specific tasks, such as classification, regression, or pattern recognition, by learning from labeled or unlabeled data. ANNs are a fundamental building block of machine learning and artificial intelligence, with applications in various domains, including computer vision, natural language processing, and speech recognition.

The basic building block of an artificial neural network is the artificial neuron, or perceptron, which takes multiple input signals, applies weights to each input, and computes a weighted sum of the inputs. The weighted sum is then passed through an activation function, which determines the output of the neuron based on a threshold or non-linear function. The output of the neuron is then passed to other neurons in the network, forming interconnected layers of neurons that process and transform information.

Artificial neural networks can be organized into several layers, including:

- Input Layer: The input layer receives input data and passes it to the neurons in the next layer for processing. Each neuron in the input layer corresponds to an input feature or dimension of the input data.

- Hidden Layers: Hidden layers are intermediate layers between the input and output layers and contain one or more layers of neurons. Hidden layers perform complex transformations and feature extraction from the input data, enabling the network to learn hierarchical representations of the data.

- Output Layer: The output layer computes the final output of the network based on the processed input data and the task being performed, such as classification, regression, or generation. The output layer typically consists of one or more neurons, depending on the number of output classes or dimensions in the task.

Artificial neural networks learn from data through a process called training, where the network’s parameters, including weights and biases, are adjusted iteratively to minimize the difference between predicted and actual outputs on a training dataset. Training is typically done using optimization algorithms, such as gradient descent, and loss functions, such as mean squared error or cross-entropy, to measure the difference between predicted and actual outputs.

There are several types of artificial neural networks, including:

- Feedforward Neural Networks: Feedforward neural networks are the simplest type of neural network, where information flows in one direction, from the input layer to the output layer, without any feedback loops. Feedforward neural networks are used for tasks such as classification, regression, and pattern recognition.

- Convolutional Neural Networks (CNNs): Convolutional neural networks are specialized neural networks designed for processing structured grid data, such as images and videos. CNNs use convolutional layers to extract spatial features from input data and pooling layers to reduce the dimensionality of the feature maps.

- Recurrent Neural Networks (RNNs): Recurrent neural networks are neural networks with recurrent connections that enable them to model sequential data and temporal dependencies. RNNs are used for tasks such as time series prediction, natural language processing, and speech recognition.

- Long Short-Term Memory (LSTM) Networks: LSTM networks are a type of recurrent neural network with specialized memory cells that can retain information over long sequences and mitigate the vanishing gradient problem. LSTM networks are widely used for tasks such as sequence prediction, language modeling, and machine translation.

Artificial neural networks have demonstrated state-of-the-art performance in various domains, including image recognition, speech recognition, natural language processing, and autonomous driving. However, training deep neural networks can be computationally intensive and requires large amounts of labeled data, computational resources, and expertise in network architecture design and hyperparameter tuning. Despite these challenges, artificial neural networks continue to advance rapidly, driven by innovations in algorithms, hardware, and data availability, and hold great promise for revolutionizing artificial intelligence and machine learning in the future.

Natural Language Processing (NLP)

Natural Language Processing (NLP) is a subfield of artificial intelligence (AI) and linguistics that focuses on enabling computers to understand, interpret, and generate human language in a way that is both meaningful and contextually relevant. NLP techniques and algorithms enable computers to analyze, process, and generate text-based data, such as written text, speech, and dialogue, to perform tasks such as sentiment analysis, language translation, speech recognition, and text generation.

NLP encompasses a wide range of tasks and techniques, including:

- Text Preprocessing: Text preprocessing involves cleaning and preparing raw text data for analysis by removing noise, punctuation, and special characters, tokenizing text into words or phrases, and normalizing text by converting it to lowercase and removing stopwords and irrelevant information.

- Text Classification: Text classification involves categorizing text documents or messages into predefined categories or classes based on their content or topics. Common text classification tasks include spam detection, sentiment analysis, topic modeling, and language identification.

- Named Entity Recognition (NER): Named Entity Recognition (NER) involves identifying and extracting named entities, such as people, organizations, locations, dates, and numerical expressions, from text documents. NER algorithms use machine learning models and rule-based approaches to detect and classify named entities in text data.

- Part-of-Speech Tagging (POS): Part-of-Speech Tagging (POS) involves assigning grammatical tags, such as nouns, verbs, adjectives, and adverbs, to words in a sentence to analyze their syntactic structure and grammatical relationships. POS tagging is used in various NLP tasks, including parsing, information extraction, and machine translation.

- Sentiment Analysis: Sentiment analysis, also known as opinion mining, involves analyzing text data to determine the sentiment or emotion expressed in the text, such as positive, negative, or neutral sentiment. Sentiment analysis algorithms use machine learning models and lexicon-based approaches to classify text sentiment at the document, sentence, or aspect level.

- Machine Translation: Machine translation involves automatically translating text from one language to another using computational methods and algorithms. Machine translation systems use statistical models, neural networks, and rule-based approaches to generate accurate and fluent translations between languages.

- Text Generation: Text generation involves generating coherent and contextually relevant text based on a given prompt or input. Text generation models, such as language models and generative adversarial networks (GANs), learn to generate human-like text by learning from large corpora of text data and capturing the underlying patterns and structures of natural language.

NLP techniques and algorithms rely on various computational approaches, including rule-based systems, statistical models, and machine learning algorithms, such as:

- Rule-based Systems: Rule-based NLP systems use predefined rules, patterns, and grammatical rules to analyze and process text data. Rule-based systems are often used for simple NLP tasks, such as text preprocessing, tokenization, and rule-based entity recognition.

- Statistical Models: Statistical NLP models use probabilistic techniques and statistical methods to analyze and process text data. Statistical models, such as hidden Markov models (HMMs) and conditional random fields (CRFs), are used for tasks such as POS tagging, named entity recognition, and machine translation.

- Machine Learning Algorithms: Machine learning algorithms, such as support vector machines (SVMs), decision trees, and neural networks, are widely used in NLP for tasks such as text classification, sentiment analysis, and machine translation. Deep learning algorithms, such as recurrent neural networks (RNNs) and transformer models, have shown state-of-the-art performance in various NLP tasks, including language modeling, text generation, and sequence-to-sequence learning.

NLP has numerous applications and use cases across various industries and domains, including:

- Customer Support: In customer support and service, NLP is used to automate responses to customer inquiries, analyze customer feedback and sentiment, and provide personalized recommendations and assistance through chatbots and virtual assistants.

- Information Retrieval: In information retrieval and search engines, NLP techniques are used to index, search, and retrieve relevant documents and web pages based on user queries and preferences. NLP algorithms analyze and process text data to rank search results and improve the relevance and accuracy of search engines.

- Healthcare: In healthcare and medical informatics, NLP is used to analyze electronic health records (EHRs), medical literature, and clinical notes to extract patient information, identify medical conditions and treatments, and support clinical decision-making and research.

- Financial Services: In financial services and fintech, NLP is used to analyze financial news, market reports, and social media sentiment to predict market trends, assess investment risks, and automate trading strategies.

- Social Media Analysis: In social media analytics and marketing, NLP is used to analyze user-generated content, sentiment, and trends on social media platforms to understand customer behavior, identify influencers, and track brand reputation and engagement.

NLP continues to advance rapidly, driven by developments in machine learning, deep learning, and natural language understanding. Recent trends in NLP include the use of transformer models, such as BERT (Bidirectional Encoder Representations from Transformers) and GPT (Generative Pre-trained Transformer), which have achieved state-of-the-art performance in various NLP tasks, including language modeling, text classification, and question answering. As NLP technologies continue to evolve, they hold great promise for enabling computers to understand and interact with human language in more natural and intuitive ways, leading to advancements in human-computer interaction, artificial intelligence, and digital communication.

Deep Learning

Deep learning is a subset of machine learning that focuses on the development and training of artificial neural networks with multiple layers, also known as deep neural networks (DNNs), to learn complex representations of data. Deep learning algorithms learn hierarchical representations of data by composing multiple layers of non-linear transformations, enabling them to automatically discover and extract features from raw data without the need for manual feature engineering.

The key components of deep learning include:

- Neural Networks: Neural networks are computational models inspired by the structure and function of biological neural networks in the human brain. A neural network consists of interconnected nodes, or artificial neurons, organized into layers, including an input layer, one or more hidden layers, and an output layer. Each neuron in the network computes a weighted sum of its input signals, applies an activation function to the sum, and passes the result to neurons in the next layer.

- Deep Neural Networks (DNNs): Deep neural networks are neural networks with multiple layers, typically ranging from tens to hundreds of layers. Deep neural networks can learn hierarchical representations of data by composing multiple layers of non-linear transformations, enabling them to capture complex patterns and relationships in the input data.

- Activation Functions: Activation functions are non-linear functions applied to the output of neurons in a neural network to introduce non-linearity and enable the network to learn complex mappings from input to output. Common activation functions include sigmoid, tanh, ReLU (Rectified Linear Unit), and softmax, which are used in different layers of the network depending on the task and architecture.

- Training Algorithms: Training algorithms are optimization algorithms used to train deep neural networks by adjusting the network’s parameters, including weights and biases, to minimize a loss function that measures the difference between predicted and actual outputs on a training dataset. Training algorithms, such as gradient descent and its variants, use backpropagation to compute gradients and update the network’s parameters iteratively.

Deep learning has achieved remarkable success in various domains and applications, including:

- Computer Vision: In computer vision, deep learning algorithms, such as convolutional neural networks (CNNs), are used for tasks such as image classification, object detection, image segmentation, and facial recognition. CNNs learn hierarchical representations of visual features from raw pixel data, enabling them to achieve state-of-the-art performance on image-related tasks.

- Natural Language Processing (NLP): In natural language processing, deep learning algorithms, such as recurrent neural networks (RNNs) and transformer models, are used for tasks such as language modeling, text classification, sentiment analysis, machine translation, and question answering. RNNs and transformers learn contextual representations of words and sentences from text data, enabling them to understand and generate human-like language.

- Speech Recognition: In speech recognition, deep learning algorithms, such as recurrent neural networks (RNNs) and convolutional neural networks (CNNs), are used to transcribe spoken language into text. Deep learning models learn acoustic and linguistic features from audio data, enabling them to recognize and transcribe speech with high accuracy.

- Healthcare: In healthcare, deep learning algorithms are used for tasks such as medical image analysis, disease diagnosis, drug discovery, and personalized medicine. Deep learning models analyze medical imaging data, electronic health records (EHRs), and genomic data to assist healthcare professionals in diagnosis and treatment decisions.

- Autonomous Vehicles: In autonomous vehicles, deep learning algorithms are used for tasks such as object detection, lane detection, obstacle avoidance, and path planning. Deep learning models process sensor data from cameras, lidar, and radar to perceive the environment and make real-time decisions for safe navigation.

Deep learning continues to advance rapidly, driven by innovations in algorithms, hardware, and data availability. Recent trends in deep learning include the development of transformer models, such as BERT (Bidirectional Encoder Representations from Transformers) and GPT (Generative Pre-trained Transformer), which have achieved state-of-the-art performance in various NLP tasks. As deep learning technologies continue to evolve, they hold great promise for revolutionizing artificial intelligence, enabling new capabilities, insights, and applications that were previously unimaginable. However, deep learning also raises challenges and concerns, including the need for large amounts of labeled data, computational resources, and expertise in model architecture design and training, as well as ethical and societal implications related to bias, privacy, and accountability.

Convolutional Neural Networks (CNNs)

Convolutional Neural Networks (CNNs) are a class of deep neural networks specially designed for processing structured grid data, such as images and videos. CNNs have revolutionized the field of computer vision by enabling machines to automatically learn hierarchical representations of visual features directly from raw pixel data, without the need for handcrafted features. CNNs are composed of multiple layers, including convolutional layers, pooling layers, and fully connected layers, which learn to extract and transform visual features from input images through a series of learned filters and transformations.

The key components of Convolutional Neural Networks include:

- Convolutional Layers: Convolutional layers are the building blocks of CNNs responsible for extracting local features from input images through convolutions with learned filters, also known as kernels. Each convolutional layer consists of multiple filters that slide across the input image, computing dot products between the filter weights and local patches of the input image to produce feature maps. Convolutional layers learn to detect low-level features, such as edges and textures, in the early layers and progressively learn more abstract and complex features in deeper layers.

- Pooling Layers: Pooling layers are used to downsample the spatial dimensions of feature maps and reduce the computational complexity of the network while preserving important features. Common pooling operations include max pooling, average pooling, and sum pooling, which aggregate information from local regions of the feature maps to produce downsampled representations with reduced spatial resolution.

- Activation Functions: Activation functions introduce non-linearity into the output of neurons in convolutional layers, enabling CNNs to learn complex mappings between input and output. Common activation functions used in CNNs include ReLU (Rectified Linear Unit), sigmoid, and tanh, which introduce non-linearities and enable the network to model complex relationships between features.

- Fully Connected Layers: Fully connected layers, also known as dense layers, are used to perform classification or regression on the learned features extracted by convolutional layers. Fully connected layers connect every neuron in one layer to every neuron in the next layer, allowing the network to learn complex decision boundaries and make predictions based on the extracted features.

Convolutional Neural Networks have demonstrated state-of-the-art performance in various computer vision tasks, including:

- Image Classification: In image classification, CNNs are used to classify images into predefined categories or classes based on their visual content. CNNs learn to extract hierarchical representations of visual features from input images and make predictions about the presence of objects, scenes, or patterns in the images.

- Object Detection: In object detection, CNNs are used to detect and localize objects of interest within images by predicting bounding boxes around object instances and class labels for each detected object. CNN-based object detection models, such as Faster R-CNN, YOLO (You Only Look Once), and SSD (Single Shot MultiBox Detector), have achieved state-of-the-art performance on benchmark datasets.

- Semantic Segmentation: In semantic segmentation, CNNs are used to segment images into pixel-level masks, where each pixel is assigned a class label corresponding to the object or category it belongs to. Semantic segmentation models, such as U-Net, SegNet, and DeepLab, enable fine-grained understanding and analysis of image content for tasks such as autonomous driving, medical imaging, and satellite imagery analysis.

- Image Generation and Style Transfer: In image generation and style transfer, CNNs are used to generate new images or transfer the style of one image onto another image. CNN-based generative models, such as Generative Adversarial Networks (GANs) and Variational Autoencoders (VAEs), learn to generate realistic images by capturing the underlying distribution of training data and sampling from it to produce novel images.

Convolutional Neural Networks continue to advance rapidly, driven by innovations in network architectures, training algorithms, and computational resources. Recent trends in CNNs include the development of lightweight architectures for resource-constrained devices, such as mobile phones and embedded systems, and the integration of attention mechanisms and self-supervised learning techniques to improve performance on challenging computer vision tasks. As CNNs continue to evolve, they hold great promise for enabling machines to perceive, understand, and interpret visual information in more sophisticated and human-like ways, leading to advancements in fields such as autonomous robotics, augmented reality, and medical imaging.

Generative Adversarial Networks (GANs)

Generative Adversarial Networks (GANs) are a class of deep learning models introduced by Ian Goodfellow and his colleagues in 2014. GANs are composed of two neural networks, a generator and a discriminator, which are trained simultaneously through a competitive process to generate realistic data samples from a given distribution. GANs have revolutionized the field of generative modeling by enabling machines to generate high-quality, realistic data samples, such as images, audio, and text, that are indistinguishable from real data.

The key components of Generative Adversarial Networks include:

- Generator: The generator is a neural network that takes random noise or latent vectors as input and generates synthetic data samples that resemble real data samples from a target distribution. The generator learns to map latent vectors to realistic data samples through a series of learned transformations and feature mappings. The goal of the generator is to produce data samples that are indistinguishable from real data samples to fool the discriminator.

- Discriminator: The discriminator is a neural network that takes input data samples, both real and synthetic, and predicts whether each sample is real or fake. The discriminator learns to distinguish between real and synthetic data samples by classifying them as real or fake based on their features and characteristics. The goal of the discriminator is to correctly classify real data samples as real and synthetic data samples generated by the generator as fake.

- Adversarial Training: GANs are trained using an adversarial training process, where the generator and discriminator are trained simultaneously in a competitive manner. During training, the generator generates synthetic data samples, which are fed into the discriminator along with real data samples. The discriminator then tries to distinguish between real and synthetic samples, while the generator tries to produce samples that are realistic enough to fool the discriminator. The training process continues iteratively until the generator produces data samples that are indistinguishable from real data samples.

- Loss Functions: GANs use two loss functions to train the generator and discriminator: the generator loss and the discriminator loss. The generator loss measures the difference between the predictions of the discriminator on synthetic samples generated by the generator and real samples, encouraging the generator to produce samples that fool the discriminator. The discriminator loss measures the difference between the predictions of the discriminator on real and synthetic samples, encouraging the discriminator to distinguish between real and fake samples accurately.

Generative Adversarial Networks have numerous applications and use cases across various domains, including:

- Image Generation: In image generation, GANs are used to generate realistic images from random noise or latent vectors. GANs can generate high-resolution, photorealistic images of faces, animals, landscapes, and other objects, which are indistinguishable from real images. GAN-based image generation models, such as DCGAN (Deep Convolutional GAN), StyleGAN, and BigGAN, have achieved state-of-the-art performance on image synthesis tasks.

- Image-to-Image Translation: In image-to-image translation, GANs are used to translate images from one domain to another while preserving semantic content and style. GANs can transform images between different visual domains, such as day to night, grayscale to color, and segmentation maps to photographs, with high fidelity and realism. GAN-based image-to-image translation models, such as CycleGAN, Pix2Pix, and SPADE (Spatially Adaptive Denormalization), have demonstrated impressive results on various image translation tasks.

- Super-Resolution: In super-resolution, GANs are used to enhance the resolution and quality of low-resolution images by generating high-resolution counterparts with finer details and textures. GANs can generate sharp, realistic images with higher spatial resolution and improved visual quality, making them suitable for applications such as digital zoom, image enhancement, and medical imaging. GAN-based super-resolution models, such as SRGAN (Super-Resolution GAN) and ESRGAN (Enhanced Super-Resolution GAN), have shown significant improvements over traditional methods for image upscaling.

- Text-to-Image Synthesis: In text-to-image synthesis, GANs are used to generate realistic images from textual descriptions or captions. GANs can learn to translate textual descriptions into visual representations by mapping semantic concepts and attributes to pixel-level details and structures. Text-to-image synthesis models based on GANs, such as AttnGAN (Attentional Generative Adversarial Network) and StackGAN, can generate diverse and photorealistic images conditioned on textual input, enabling applications such as image captioning, visual storytelling, and content creation.

- Video Generation: In video generation, GANs are used to generate realistic video sequences from random noise or latent vectors. GANs can generate coherent, dynamic sequences of frames with smooth transitions and realistic motion, making them suitable for applications such as video synthesis, video prediction, and video editing. GAN-based video generation models, such as VGAN (Video Generative Adversarial Network) and TGAN (Temporal Generative Adversarial Network), have shown promising results in generating high-quality, diverse video content.

Generative Adversarial Networks continue to advance rapidly, driven by innovations in network architectures, training algorithms, and applications. Recent trends in GANs include the development of conditional GANs, which can generate samples conditioned on additional information or constraints, such as class labels, attributes, and textual descriptions, as well as the integration of GANs with other deep learning techniques, such as reinforcement learning and self-supervised learning, to improve performance and scalability. As GANs continue to evolve, they hold great promise for enabling machines to generate and manipulate realistic data samples in ways that were previously impossible, leading to advancements in computer graphics, virtual reality, content creation, and beyond.

Reinforcement Learning

Reinforcement Learning (RL) is a branch of machine learning concerned with how agents ought to take actions in an environment to maximize some notion of cumulative reward. Unlike supervised learning, where the algorithm is trained on labeled data, or unsupervised learning, where the algorithm discovers patterns in unlabeled data, reinforcement learning is about taking suitable actions to maximize reward in a particular situation.

The key components of reinforcement learning include:

- Agent: The entity responsible for making decisions and taking actions in an environment. The agent interacts with the environment by observing its current state and selecting actions to perform based on its policy.

- Environment: The external system with which the agent interacts. The environment provides feedback to the agent in the form of rewards or penalties based on the actions taken by the agent.

- State: The current situation or configuration of the environment at a particular time step. The state is a representation of relevant information that the agent uses to make decisions.

- Action: The set of possible moves or decisions that the agent can take in a given state. Actions can be discrete or continuous, depending on the nature of the problem.

- Reward: The feedback signal provided by the environment to the agent after taking an action in a particular state. The reward indicates the immediate benefit or cost associated with the action and serves as the basis for learning.

The main goal of reinforcement learning is to learn a policy that maps states to actions in a way that maximizes the cumulative reward over time. This is typically done through the use of value functions or policy gradients, which help the agent learn which actions are likely to lead to higher rewards.

Reinforcement learning algorithms can be categorized into several types, including:

- Value-Based Methods: Value-based methods aim to find the optimal value function, which represents the expected cumulative reward of taking an action in a given state and following a particular policy. Examples of value-based algorithms include Q-learning and Deep Q-Networks (DQN).

- Policy-Based Methods: Policy-based methods directly parameterize the policy, which maps states to actions, and aim to find the optimal policy that maximizes the expected cumulative reward. Examples of policy-based algorithms include REINFORCE and Proximal Policy Optimization (PPO).

- Actor-Critic Methods: Actor-Critic methods combine aspects of both value-based and policy-based approaches by maintaining separate actor and critic networks. The actor network learns the policy, while the critic network learns the value function. Examples of actor-critic algorithms include Advantage Actor-Critic (A2C) and Deep Deterministic Policy Gradient (DDPG).

Reinforcement learning has numerous applications and use cases across various domains, including:

- Game Playing: In game playing, reinforcement learning algorithms can learn to play complex games, such as chess, Go, and video games, by interacting with the environment and learning from feedback. Reinforcement learning has achieved superhuman performance in games such as AlphaGo and Dota 2.

- Robotics: In robotics, reinforcement learning algorithms can be used to train autonomous agents to perform tasks such as navigation, manipulation, and object grasping in real-world environments. Reinforcement learning enables robots to learn complex behaviors and adapt to changing conditions.

- Recommendation Systems: In recommendation systems, reinforcement learning algorithms can learn to personalize recommendations for users by optimizing long-term user engagement or satisfaction. Reinforcement learning can help improve the effectiveness of recommendation systems by incorporating user feedback and preferences.

- Finance: In finance, reinforcement learning algorithms can be used for algorithmic trading, portfolio management, and risk assessment. Reinforcement learning enables traders to learn optimal trading strategies and adapt to changing market conditions in real-time.

- Healthcare: In healthcare, reinforcement learning algorithms can be used for personalized treatment planning, drug discovery, and patient monitoring. Reinforcement learning enables healthcare providers to optimize treatment protocols and make decisions that maximize patient outcomes.

Reinforcement learning continues to advance rapidly, driven by developments in algorithms, hardware, and applications. Recent trends in reinforcement learning include the use of deep neural networks to represent value functions and policies, the integration of imitation learning and meta-learning techniques to bootstrap learning from human demonstrations or past experiences, and the exploration of multi-agent reinforcement learning for collaborative and competitive scenarios. As reinforcement learning techniques continue to evolve, they hold great promise for solving complex decision-making problems and enabling intelligent, autonomous systems to learn and adapt in dynamic environments.

Transfer Learning

Transfer learning is a machine learning technique where a model trained on one task is reused or adapted for a different but related task. Instead of training a model from scratch on a new dataset, transfer learning leverages the knowledge gained from solving one problem to solve a related problem more efficiently. Transfer learning is particularly useful when the target task has limited data or computational resources, as it allows the model to benefit from pre-trained representations learned from larger, more diverse datasets.

The main idea behind transfer learning is to transfer knowledge from a source domain or task to a target domain or task by fine-tuning the parameters of a pre-trained model on the target data. There are several approaches to transfer learning, including:

- Feature Extraction: In feature extraction, the pre-trained model is used as a fixed feature extractor, where the parameters of the model are frozen, and only the output features of one or more intermediate layers are used as input to a new classifier or regressor. By leveraging the learned representations from the pre-trained model, feature extraction allows the model to capture meaningful patterns and relationships in the target data without retraining the entire model.

- Fine-Tuning: In fine-tuning, the pre-trained model is adapted to the target task by fine-tuning its parameters on the target data while preserving the knowledge learned from the source task. The parameters of the pre-trained model are updated using gradient descent or other optimization techniques to minimize the loss on the target task. Fine-tuning allows the model to adapt to the specific characteristics of the target data and learn task-specific features while retaining the general knowledge captured by the pre-trained model.

Transfer learning has numerous applications and use cases across various domains, including:

- Computer Vision: In computer vision, transfer learning is commonly used for tasks such as image classification, object detection, and image segmentation. Pre-trained convolutional neural network (CNN) models, such as VGG, ResNet, and Inception, trained on large-scale image datasets, such as ImageNet, are often used as feature extractors or fine-tuned on domain-specific datasets for tasks such as medical imaging, satellite imagery analysis, and wildlife monitoring.

- Natural Language Processing (NLP): In natural language processing, transfer learning is widely used for tasks such as text classification, sentiment analysis, and named entity recognition. Pre-trained language models, such as BERT (Bidirectional Encoder Representations from Transformers), GPT (Generative Pre-trained Transformer), and RoBERTa, trained on large text corpora, are fine-tuned on domain-specific text data for tasks such as customer support, social media analysis, and financial sentiment analysis.

- Healthcare: In healthcare, transfer learning is used for medical image analysis, disease diagnosis, and personalized treatment planning. Pre-trained CNN models trained on large-scale medical imaging datasets, such as ChestX-ray14 and MURA, are fine-tuned on patient-specific imaging data for tasks such as tumor detection, pathology detection, and treatment response prediction.