Industrial communication protocols serve as the backbone of connectivity in the complex landscape of automation and control systems. Among these, Modbus stands out as a widely used and versatile protocol, facilitating the exchange of information between devices in a myriad of industrial applications. Profibus follows suit, offering a standardized communication protocol that ensures interoperability among diverse devices in process automation.

Industrial Communication Protocols

DeviceNet, another key player, provides a robust and deterministic communication protocol for industrial networks, particularly in scenarios where plug-and-play capabilities are paramount. HART (Highway Addressable Remote Transducer) protocol, often used in process industries, enables communication with smart field devices, enhancing the efficiency of measurement and control systems.

As we navigate the realm of industrial communication, OPC (OLE for Process Control) emerges as a standard for interoperability, facilitating seamless data exchange between different systems. EtherNet/IP, built on standard Ethernet technology, combines the benefits of industrial communication with the ubiquity of Ethernet, providing a versatile solution for various applications.

Profinet, on the other hand, establishes itself as a communication protocol designed for industrial automation, ensuring real-time data exchange in a flexible and high-performance environment. CAN (Controller Area Network), recognized for its robustness in automotive applications, extends its influence into industrial settings, offering reliable communication among devices.

BACnet (Building Automation and Control Networks) caters specifically to building automation, providing a standardized protocol for communication among various devices in a building automation system. MQTT (Message Queuing Telemetry Transport) shines in scenarios where lightweight and efficient communication is essential, especially in the context of IoT (Internet of Things) and industrial applications.

These diverse industrial communication protocols collectively form the intricate web that enables devices, systems, and processes to communicate and collaborate seamlessly in the dynamic landscape of industrial automation.

Within the realm of industrial communication protocols, DeviceNet takes a prominent position as a robust and deterministic network, designed for real-time communication among industrial devices. HART (Highway Addressable Remote Transducer), renowned for its compatibility with traditional analog signals, provides a standardized protocol that enables two-way communication with intelligent field devices, enhancing the capabilities of measurement and control systems.

OPC (OLE for Process Control) continues to be a linchpin in the landscape, fostering interoperability by facilitating the exchange of data between disparate systems. EtherNet/IP, built on the foundation of standard Ethernet, seamlessly merges industrial communication with the ubiquity of Ethernet, offering flexibility and high-performance data exchange across diverse applications.

Profinet, a powerful communication protocol in industrial automation, stands out for its real-time capabilities, supporting high-speed and synchronized communication among devices. CAN (Controller Area Network), known for its resilience in automotive applications, extends its influence into industrial contexts, providing reliable communication and network management.

BACnet (Building Automation and Control Networks) remains a stalwart in the realm of building automation, ensuring standardized communication and interoperability among devices within a building automation system. MQTT (Message Queuing Telemetry Transport), with its lightweight and efficient nature, finds its niche in industrial applications, particularly in the era of IoT (Internet of Things).

WirelessHART introduces wireless capabilities into industrial communication, offering a flexible solution for scenarios where wired connections are impractical. Foundation Fieldbus, designed for process automation, facilitates communication among field devices, contributing to the efficiency and flexibility of industrial processes.

RS-232 and RS-485, though considered traditional, continue to play vital roles in industrial communication, providing serial communication standards for connecting various devices in industrial settings. AS-Interface (Actuator Sensor Interface) simplifies the wiring and connection of sensors and actuators, streamlining communication in scenarios where simplicity and efficiency are paramount.

In this dynamic landscape of industrial communication protocols, the intricate interplay of these standards ensures the seamless exchange of data and commands, fostering efficient and synchronized operation in industrial automation and control systems.

IEC 61850 emerges as a key standard in industrial communication protocols, specifically tailored for the power utility sector. This standardized protocol facilitates seamless communication between intelligent electronic devices (IEDs) within substations, ensuring efficient and interoperable data exchange. DNP3 (Distributed Network Protocol), with its focus on remote telemetry and control, finds applications in utility and industrial sectors, offering robust communication for critical infrastructure.

LON (Local Operating Network) protocol establishes itself as a versatile solution for building automation, connecting various devices in a local network to enhance control and monitoring capabilities. ISA100.11a, designed for wireless communication in industrial automation, provides a reliable framework for secure and scalable communication, particularly in scenarios where wired connections are impractical.

Ethernet Powerlink, built upon standard Ethernet, offers real-time communication capabilities suitable for applications requiring deterministic and synchronized data exchange. ControlNet, a protocol developed by Rockwell Automation, focuses on real-time industrial control applications, providing high-speed communication for interconnected devices within a network.

EtherCAT, known for its real-time capabilities, stands as a protocol designed for high-performance industrial communication, ensuring precise synchronization and low latency in automation systems. Zigbee, a wireless communication protocol, finds applications in industrial settings for low-power and short-range communication, particularly in sensor networks.

BLE (Bluetooth Low Energy) extends its influence into industrial communication protocols, offering energy-efficient and reliable communication for low-data-rate applications. Modbus TCP/IP, an extension of the Modbus protocol, utilizes standard TCP/IP networks for communication, providing versatility and compatibility with Ethernet-based systems.

CANopen, an open communication protocol based on CAN (Controller Area Network), facilitates communication and networking among devices in embedded systems, offering a standardized approach in various industrial applications. KNX (Konnex), tailored for building automation, provides a standardized platform for communication among diverse devices, promoting interoperability in smart buildings.

As industrial communication protocols continue to evolve, these standards play pivotal roles in shaping the efficiency, reliability, and interoperability of communication networks within the diverse landscape of industrial automation.

TSN (Time-Sensitive Networking) emerges as a transformative force in industrial communication protocols, addressing the need for precise timing and synchronization in time-critical applications. This standard enhances Ethernet communication, providing a reliable framework for real-time data exchange in industrial automation settings. Wireless Sensor Networks, leveraging wireless communication technologies, offer a flexible solution for connecting sensors and devices without the constraints of physical cables, contributing to the scalability and adaptability of industrial systems.

Fieldbus Foundation, a communication protocol in process automation, enables the seamless exchange of data among field devices, enhancing the efficiency and control capabilities of industrial processes. BACnet/IP extends the capabilities of BACnet to operate over IP networks, promoting interoperability and communication among diverse devices in building automation systems.

POWERLINK, built on Ethernet communication, provides real-time capabilities suitable for demanding industrial applications, ensuring precise and deterministic communication. Wiegand Interface, although commonly associated with access control systems, finds applications in industrial settings for secure and efficient communication between sensors and controllers.

M-Bus (Meter-Bus) protocol specializes in communication for remote reading of utility meters, making it a valuable standard in industrial applications where metering and monitoring are crucial. Sercos, a real-time communication protocol for motion control applications, ensures synchronized and precise communication among devices in automation systems.

EnOcean stands out as a wireless communication standard specifically designed for energy harvesting devices, offering a battery-less and wire-free solution for communication in industrial environments. ISA-100 Wireless, a robust and secure protocol, caters to wireless communication in industrial automation, providing flexibility and reliability in challenging environments.

M2M (Machine-to-Machine) Communication, encompassing a range of communication technologies, plays a pivotal role in industrial applications where devices exchange information without human intervention. CAN FD (Flexible Data-rate), an extension of the CAN protocol, enhances data transfer rates and payload sizes, catering to the evolving needs of industrial communication.

Modbus RTU, a variant of the Modbus protocol, operates over serial communication, providing a straightforward and widely used standard for connecting industrial devices. BACnet MS/TP (Master-Slave/Token-Passing), designed for building automation, ensures efficient communication between devices over twisted-pair networks.

In this ever-evolving landscape of industrial communication protocols, these standards collectively shape the connectivity, efficiency, and adaptability of communication networks, fostering innovation and advancements in industrial automation.

CIP (Common Industrial Protocol) stands as a unifying force in industrial communication protocols, providing a comprehensive suite of protocols for communication among diverse devices in industrial automation. IO-Link, a point-to-point communication protocol, enhances the connectivity and intelligence of sensors and actuators, fostering efficient communication in smart factories.

OPC UA (Unified Architecture) plays a pivotal role in industrial communication by providing a platform-independent, service-oriented architecture for secure and reliable data exchange. J1939, originally developed for the automotive industry, extends its influence into industrial applications, providing a standardized communication protocol for heavy-duty vehicles and equipment.

ISA-95, a standard for the integration of enterprise and control systems, promotes interoperability and efficiency by defining models and terminology for communication between different levels of industrial systems. TSN (Time-Sensitive Networking), with its focus on deterministic and synchronized communication, becomes increasingly crucial in industrial applications where precise timing is essential.

Wireless communication technologies such as WirelessHART and Zigbee continue to shape the landscape of industrial communication, offering flexible and efficient solutions for scenarios where wired connections are impractical. BLE (Bluetooth Low Energy) finds applications in industrial settings for low-power and short-range communication, particularly in the context of IoT (Internet of Things) devices.

Modbus RTU, a widely used protocol in industrial automation, operates over serial communication, providing a straightforward and versatile solution for connecting devices. BACnet MS/TP (Master-Slave/Token-Passing) extends BACnet capabilities to twisted-pair networks, facilitating efficient communication between devices in building automation.

CAN FD (Flexible Data-rate) extends the capabilities of the traditional CAN protocol, offering higher data transfer rates and larger payload sizes to meet the evolving requirements of industrial communication. MQTT-SN (MQTT for Sensor Networks) optimizes MQTT for wireless sensor networks, providing a lightweight and efficient communication protocol for IoT devices.

OPC DA (Data Access), a foundational component of OPC, focuses on real-time data exchange in industrial communication, enabling seamless access to data from diverse devices and systems. The intricate dance of these industrial communication protocols ensures the connectivity, reliability, and efficiency required for the intricate orchestration of industrial automation systems.

EMS Automation Solutions

Introducing EMS Automation Solutions: Pioneering Excellence in Industrial Automation

At EMS Automation Solutions, we stand at the forefront of innovation, offering cutting-edge industrial automation solutions that redefine the way industries operate. With a relentless commitment to precision, efficiency, and reliability, we empower businesses to navigate the complexities of the modern industrial landscape seamlessly.

Comprehensive Industrial Automation Portfolio

Our extensive portfolio encompasses a diverse range of industrial automation solutions tailored to meet the unique needs of our clients. From PLC (Programmable Logic Controller) programming to SCADA (Supervisory Control and Data Acquisition) systems, robotics, and state-of-the-art control valves, we deliver holistic automation solutions that drive productivity and operational excellence.

PLC Programming Excellence

Unlock the full potential of your industrial processes with our unparalleled PLC programming expertise. Our skilled team of engineers crafts custom solutions that optimize control, enhance reliability, and streamline processes. From designing intricate control logic to seamless integration with other automation components, our PLC solutions are tailored to elevate your production capabilities.

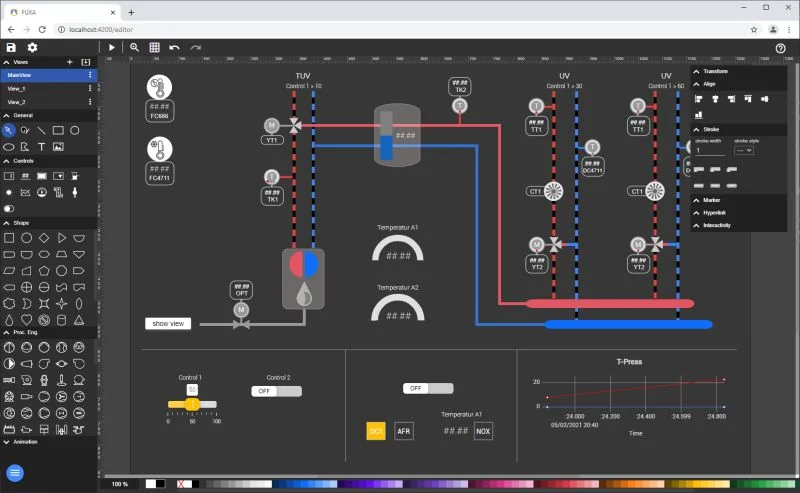

SCADA Systems for Real-Time Control

Experience real-time control and monitoring like never before with our SCADA systems. EMS Automation Solutions leverages advanced SCADA technologies to provide a centralized platform for overseeing and managing diverse industrial processes. Gain insights, analyze data, and make informed decisions to propel your business into a new era of efficiency.

Robotics Redefined

Embrace the future of manufacturing with our state-of-the-art robotics solutions. From automated assembly lines to intricate tasks requiring precision, our robotics systems are engineered to enhance speed, accuracy, and safety in your operations. Collaborative robots, robotic arms, and automated guided vehicles – we bring a spectrum of robotics solutions to elevate your manufacturing prowess.

Control Valves for Precision Flow Management

Ensure optimal fluid flow control with our premium control valves. Whether it’s mitigating cavitation, addressing flashing issues, or managing noise levels, EMS Automation Solutions provides a comprehensive range of control valves designed for durability, efficiency, and precise control. Our valves are crafted to seamlessly integrate into your processes, offering reliability in every operation.

Global Reach, Local Expertise

With a global presence, EMS Automation Solutions combines international reach with local expertise. Our teams collaborate closely with clients to understand their unique challenges and deliver bespoke solutions. From conceptualization to implementation and ongoing support, we are your trusted partner throughout the automation journey.

Sustainable Automation Practices

EMS Automation Solutions is committed to sustainable automation practices. We incorporate energy-efficient technologies, promote waste reduction, and design automation solutions that align with eco-friendly principles. Join us in building a future where automation and sustainability go hand in hand.

Partner with EMS Automation Solutions for Tomorrow’s Automation Today

As industries evolve, so do we. EMS Automation Solutions is not just a provider of automation services – we are architects of innovation, architects of efficiency, and architects of your success. Partner with us to transform your industrial processes and embark on a journey towards unparalleled automation excellence. Elevate your operations with EMS Automation Solutions – where the future of automation begins today!