A waterjet cutting machine is a machine that uses a high-velocity jet of water to cut through a variety of materials. The water is pressurized to very high levels, up to 60,000 psi, and then focused through a small nozzle. This creates a jet of water that is powerful enough to cut through steel, titanium, and even glass.

Waterjet cutting machines are used in a wide variety of industries, including aerospace, automotive, construction, and manufacturing. They are also used by hobbyists and artists to create unique pieces of art and jewelry.

Components of a Waterjet Cutting Machine

A waterjet cutting machine typically consists of the following components:

- Waterjet pump: The waterjet pump is responsible for pressurizing the water to very high levels.

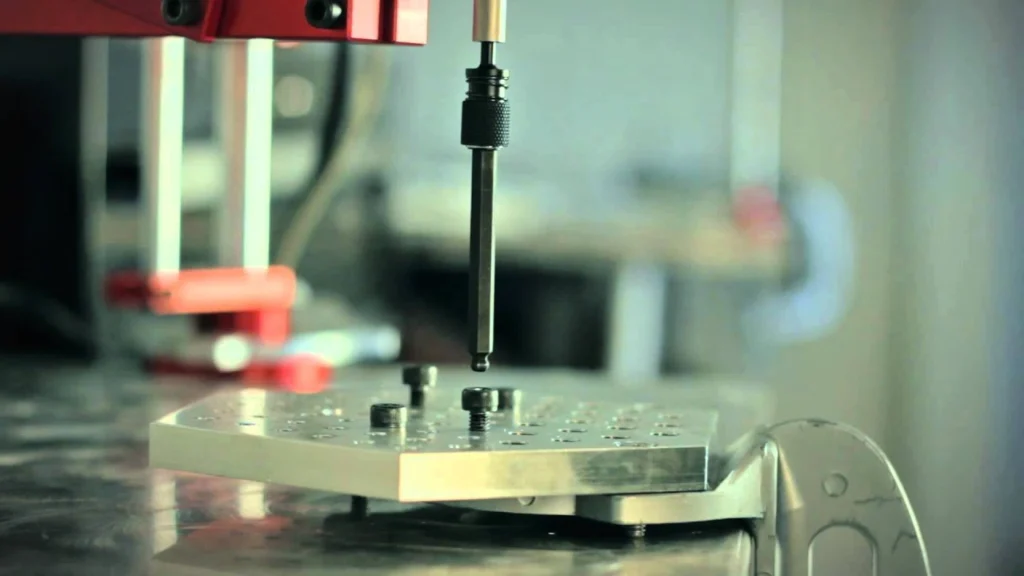

- Cutting head: The cutting head contains the nozzle that focuses the water jet.

- CNC controller: The CNC controller is used to control the movement of the cutting head.

- Worktable: The worktable is where the material to be cut is placed.

How a Waterjet Cutting Machine Works

A waterjet cutting machine works by first pressurizing the water to very high levels. The water is then focused through a small nozzle, creating a high-velocity jet of water. The jet of water is then directed at the material to be cut. The water jet cuts through the material by a process called erosion.

Advantages of Waterjet Cutting Machines

Waterjet cutting machines offer a number of advantages over other cutting methods, such as laser cutting and plasma cutting. Some of the advantages of waterjet cutting machines include:

- Precision: Waterjet cutting machines can produce very precise cuts with a tolerance of +/- 0.001 inches.

- Versatility: Waterjet cutting machines can cut through a wide variety of materials, including metals, plastics, glass, and stone.

- No heat-affected zone: Waterjet cutting does not produce any heat, so there is no heat-affected zone. This makes it ideal for cutting sensitive materials that could be damaged by heat.

- Environmentally friendly: Waterjet cutting is a very environmentally friendly process. It does not produce any fumes or dust, and it uses very little water.

Applications of Waterjet Cutting Machines

Waterjet cutting machines are used in a wide variety of industries, including:

- Aerospace: Waterjet cutting machines are used to cut aircraft components, such as engine parts and landing gear.

- Automotive: Waterjet cutting machines are used to cut automotive parts, such as car bodies, bumpers, and wheels.

- Construction: Waterjet cutting machines are used to cut construction materials, such as metal beams, concrete slabs, and glass.

- Manufacturing: Waterjet cutting machines are used to cut a wide variety of manufactured products, such as medical implants, electronic components, and food packaging.

- Art and jewelry: Waterjet cutting machines are used by artists and jewelers to create unique pieces of art and jewelry.

Conclusion

Waterjet cutting machines are versatile and powerful cutting tools that can be used to cut through a wide variety of materials. Waterjet cutting machines are used in a wide range of industries, from aerospace to manufacturing to art and jewelry.

Waterjet Cutting Machine

Waterjet cutting systems use a powerful stream of water to cut through a variety of materials. The water is pressurized to very high levels, up to 60,000 psi, and then focused through a small nozzle. This creates a jet of water that is powerful enough to cut through steel, titanium, and even glass.

Waterjet cutting systems are used in a wide variety of industries, including aerospace, automotive, construction, and manufacturing. They are also used by hobbyists and artists to create unique pieces of art and jewelry.

Benefits of Waterjet Cutting

Waterjet cutting offers a number of benefits over other cutting methods, such as laser cutting and plasma cutting. Some of the benefits of waterjet cutting include:

- Precision: Waterjet cutting systems can produce very precise cuts with a tolerance of +/- 0.001 inches.

- Versatility: Waterjet cutting systems can cut through a wide variety of materials, including metals, plastics, glass, and stone.

- No heat-affected zone: Waterjet cutting does not produce any heat, so there is no heat-affected zone. This makes it ideal for cutting sensitive materials that could be damaged by heat.

- Environmentally friendly: Waterjet cutting is a very environmentally friendly process. It does not produce any fumes or dust, and it uses very little water.

Types of Waterjet Cutting Systems

There are two main types of waterjet cutting systems: abrasive and non-abrasive.

- Abrasive waterjet cutting systems use a mixture of water and abrasive material, such as garnet or aluminum oxide, to cut through materials. Abrasive waterjet cutting systems are capable of cutting through the thickest and hardest materials.

- Non-abrasive waterjet cutting systems use only water to cut through materials. Non-abrasive waterjet cutting systems are typically used to cut thinner materials, such as plastics and sheet metal.

Applications of Waterjet Cutting

Waterjet cutting is used in a wide variety of industries, including:

- Aerospace: Waterjet cutting is used to cut aircraft components, such as engine parts and landing gear.

- Automotive: Waterjet cutting is used to cut automotive parts, such as car bodies, bumpers, and wheels.

- Construction: Waterjet cutting is used to cut construction materials, such as metal beams, concrete slabs, and glass.

- Manufacturing: Waterjet cutting is used to cut a wide variety of manufactured products, such as medical implants, electronic components, and food packaging.

- Art and jewelry: Waterjet cutting is used by artists and jewelers to create unique pieces of art and jewelry.

Conclusion

Waterjet cutting systems are versatile and powerful cutting tools that can be used to cut through a wide variety of materials. Waterjet cutting systems are used in a wide range of industries, from aerospace to manufacturing to art and jewelry.