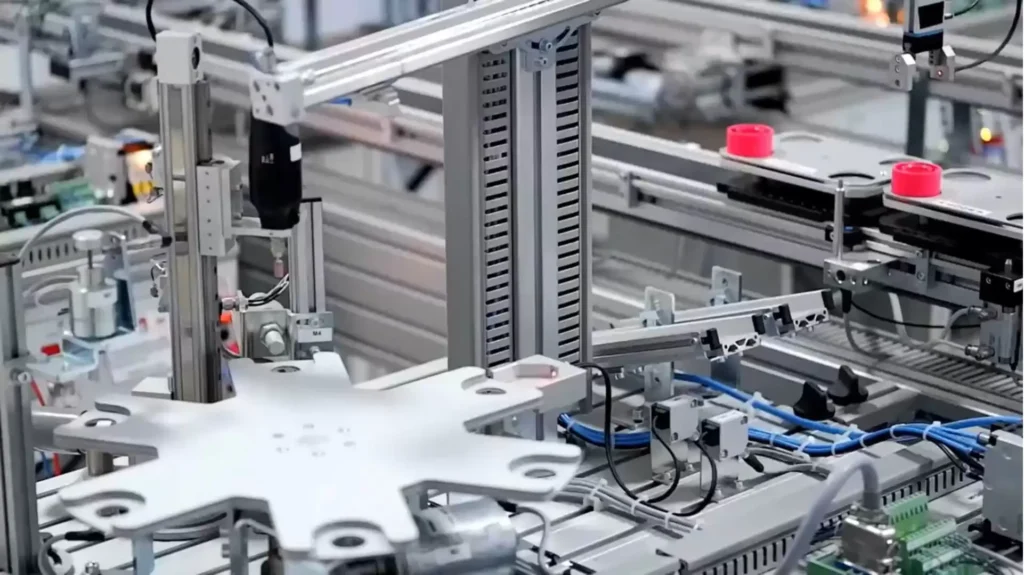

A dial indexing machine is a type of machine that uses a rotating table, or dial, to index workpieces from one station to the next. The dial is typically divided into multiple stations, each of which performs a specific task in the assembly or manufacturing process. The workpieces are loaded onto the dial at one station and then rotated to the next station, where the next task is performed. This process continues until the workpiece is complete, at which point it is unloaded from the dial.

Dial indexing machines are used in a wide variety of industries, including automotive, electronics, food and beverage, and consumer goods. They are particularly well-suited for assembling or manufacturing products that have a high number of components or that require a high degree of precision.

Dial indexing machines offer a number of advantages, including:

- Increased productivity: Dial indexing machines can help to increase productivity by reducing the time required to assemble or manufacture products. This is because the machines can perform multiple tasks simultaneously and can also be used to assemble or manufacture products in parallel.

- Improved quality: Dial indexing machines can help to improve the quality of assembled or manufactured products by reducing the risk of errors. This is because the machines can be programmed to perform tasks consistently and accurately.

- Reduced costs: Dial indexing machines can help to reduce the costs associated with assembly or manufacturing by eliminating the need for manual labor. This can free up workers to perform other tasks or to focus on quality control.

- Increased safety: Dial indexing machines can help to improve safety by reducing the risk of accidents and injuries. This is because the machines can be programmed to perform tasks that would otherwise be hazardous for humans to perform.

Dial indexing machines can be automated to a high degree, using programmable logic controllers (PLCs), robots, and other automated equipment. This can help to further increase productivity, improve quality, and reduce costs.

Here are some examples of how dial indexing machines are used in industry:

- In the automotive industry, dial indexing machines are used to assemble car doors, dashboards, and other components.

- In the electronics industry, dial indexing machines are used to assemble circuit boards and other electronic devices.

- In the food and beverage industry, dial indexing machines are used to fill and seal containers, such as bottles, cans, and bags.

- In the consumer goods industry, dial indexing machines are used to assemble toys, appliances, and other products.

Dial indexing machines can be a valuable asset for businesses that need to assemble or manufacture products quickly, accurately, and cost-effectively.

Dial Indexing Machines in the Automotive Industry

In the automotive industry, dial indexing machines, also known as rotary indexing machines, are specialized manufacturing systems used for the high-speed and high-precision assembly of automotive components and subassemblies. These machines are designed to efficiently and consistently perform multiple assembly tasks on rotating indexing tables. Here are some key aspects of dial indexing machines in the automotive industry:

- Indexing Table: Dial indexing machines feature a rotary indexing table with multiple workstations or stations positioned around the circumference. The indexing table rotates in a controlled manner, moving the workpieces or components from one station to the next.

- High-Speed Assembly: These machines are capable of high-speed assembly, making them suitable for automotive manufacturing where rapid production is essential.

- Multi-Tasking: Each station on the indexing table is equipped with specific tools, equipment, or processes for various assembly tasks. This can include tasks like component insertion, fastening, welding, sealing, and quality inspections.

- Efficiency and Precision: Dial indexing machines offer high levels of efficiency and precision. The synchronized rotation of the table ensures that components are precisely positioned and aligned for assembly.

- Customizable Tooling: The tooling at each station can be customized to accommodate different assembly requirements, making the machines versatile for various automotive components and subassemblies.

- Quality Control: Quality checks and inspections can be integrated into the machine to ensure that each assembled component meets the required quality and safety standards.

- Modular Design: Dial indexing machines are often designed in a modular fashion, making it easier to adapt or expand the assembly process as automotive production needs change.

- Flexibility: These machines can be configured to handle different components and subassemblies, making them flexible for automotive manufacturers producing a variety of vehicles and components.

- Ergonomics: Dial indexing machines are designed with operator ergonomics in mind, as they are typically equipped with easy access to workstations, reducing operator fatigue and enhancing safety.

- Integration with Automation: Automation elements, such as robotic arms and vision systems, can be integrated into dial indexing machines to further enhance the efficiency and precision of the assembly process.

- Scalability: Automotive manufacturers can scale production by using multiple dial indexing machines or by integrating them into larger assembly lines.

- Reduced Floor Space: These machines are known for their compact footprint, which can be especially valuable in facilities where space is limited.

Dial indexing machines are commonly used in the automotive industry for tasks such as engine component assembly, transmission assembly, brake system assembly, and more. They play a significant role in optimizing the assembly process, increasing production throughput, and maintaining quality standards in the automotive manufacturing sector.

Dial Indexing Machines in the Electronics Industry

In the electronics industry, dial indexing machines, also known as rotary indexing machines, are specialized manufacturing systems used for the assembly and production of electronic components and devices. These machines utilize a rotating indexing table with multiple workstations positioned around the circumference. Dial indexing machines are designed to efficiently and accurately perform various assembly tasks on electronic components. Here are some key aspects of dial indexing machines in the electronics industry:

- Indexing Table: The core feature of a dial indexing machine is its rotary indexing table. This table rotates in a controlled manner, moving the electronic components from one station to the next.

- High Precision: Dial indexing machines are capable of high-precision assembly, making them suitable for the electronics industry, where minute details and exact positioning are crucial.

- Multiple Assembly Stations: Each station on the indexing table is equipped with specific tools, equipment, or processes for various assembly tasks. This can include tasks like component placement, soldering, adhesive application, testing, and quality control.

- Customized Tooling: The tooling at each station can be customized to accommodate different assembly requirements, making the machines versatile for various electronic components and devices.

- High Speed: These machines are capable of high-speed assembly, allowing for efficient production of electronic components and devices.

- Efficiency: The synchronized rotation of the indexing table ensures that components are precisely positioned and aligned for assembly, reducing assembly time and enhancing efficiency.

- Quality Control: Dial indexing machines often incorporate quality checks and inspections to ensure that each assembled component or device meets the required quality and reliability standards.

- Modular Design: These machines are often designed with modularity in mind, allowing for easy adaptation and expansion of the assembly process as electronic manufacturing needs evolve.

- Flexibility: Dial indexing machines can be configured to handle various electronic components, making them flexible for electronics manufacturers producing a range of devices.

- Ergonomics: Operator ergonomics are considered in the design of these machines, with easy access to workstations to reduce operator fatigue and enhance safety.

- Automation Integration: Automation elements, such as robotic arms, vision systems, and pick-and-place devices, can be integrated into dial indexing machines to further enhance precision and speed in the assembly process.

- Scalability: Electronics manufacturers can scale production by using multiple dial indexing machines or by integrating them into larger assembly lines.

Dial indexing machines are commonly used in the electronics industry for tasks such as printed circuit board (PCB) assembly, semiconductor device assembly, display panel assembly, and the assembly of various electronic devices, such as smartphones, tablets, and consumer electronics. They play a significant role in optimizing the assembly process, increasing production throughput, and maintaining quality standards in electronic manufacturing.

Dial Indexing Machines in the Food and Beverage Industry

In the food and beverage industry, dial indexing machines are specialized manufacturing systems used for the assembly, filling, and packaging of food and beverage products. These machines employ a rotating indexing table with multiple workstations, allowing for efficient and precise processing of food and beverage items. Here are some key aspects of dial indexing machines in the food and beverage industry:

- Indexing Table: Dial indexing machines feature a circular indexing table with multiple workstations positioned around the perimeter. The table rotates in a controlled manner, moving food and beverage products from one station to the next.

- High Precision: These machines are capable of high-precision assembly, filling, and packaging, ensuring the accurate and consistent processing of food and beverage items.

- Multiple Assembly Stations: Each station on the indexing table is equipped with specific tools, equipment, or processes for various assembly tasks, such as filling, sealing, capping, labeling, and quality control.

- Customized Tooling: The tooling at each station can be customized to accommodate different food and beverage products, containers, and packaging requirements, making the machines adaptable for various products.

- Efficiency and Speed: Dial indexing machines are designed for high-speed processing, allowing for efficient production and packaging of food and beverage items.

- Quality Control: Quality checks and inspections are often integrated into the machines to ensure that each processed product meets the required quality and safety standards.

- Flexibility: These machines can be configured to handle various food and beverage products, making them suitable for a range of items, from bottled beverages to packaged snacks.

- Ergonomics: Operator ergonomics are considered in the design of dial indexing machines to provide easy access to workstations, reduce operator fatigue, and enhance safety.

- Automation Integration: Automation elements, such as robotic arms, vision systems, and conveyor systems, can be integrated into dial indexing machines to further enhance precision and speed in the processing and packaging processes.

- Hygiene and Food Safety: In the food and beverage industry, hygiene and food safety are paramount. Dial indexing machines are designed with features that facilitate easy cleaning and sanitization, reducing the risk of product contamination.

- Packaging and Labeling: These machines can be configured to handle various packaging and labeling tasks, such as filling containers, applying caps, seals, and labels, and arranging packaged products for distribution.

- Scalability: Food and beverage manufacturers can scale production by using multiple dial indexing machines or by integrating them into larger production lines.

Dial indexing machines are commonly used in the food and beverage industry for tasks such as filling and capping beverage bottles, packaging snack foods, assembling food trays, and preparing ready-to-eat meals. They play a significant role in optimizing the processing and packaging of food and beverage products, increasing production throughput, and maintaining quality and safety standards in the food and beverage manufacturing sector.

Dial Indexing Machines in the Consumer Goods Industry

In the consumer goods industry, dial indexing machines, also known as rotary indexing machines, are specialized manufacturing systems used for the assembly, filling, packaging, and processing of a wide range of consumer products. These machines employ a rotating indexing table with multiple workstations, allowing for efficient and precise processing of consumer goods. Here are key aspects of dial indexing machines in the consumer goods industry:

- Indexing Table: Dial indexing machines feature a circular indexing table with multiple workstations positioned around the perimeter. The table rotates in a controlled manner, moving consumer products from one station to the next.

- High Precision: These machines are capable of high-precision assembly, filling, and packaging, ensuring the accurate and consistent processing of consumer goods.

- Multiple Assembly Stations: Each station on the indexing table is equipped with specific tools, equipment, or processes for various assembly tasks, such as filling, sealing, capping, labeling, quality control, and other manufacturing processes.

- Customized Tooling: The tooling at each station can be customized to accommodate different consumer goods, containers, and packaging requirements, making the machines adaptable for various products.

- Efficiency and Speed: Dial indexing machines are designed for high-speed processing, allowing for efficient production and packaging of consumer goods, particularly in high-volume manufacturing.

- Quality Control: Quality checks and inspections are often integrated into the machines to ensure that each processed product meets the required quality and safety standards.

- Flexibility: These machines can be configured to handle various consumer products, making them suitable for a wide range of items, including appliances, electronics, furniture, and more.

- Ergonomics: Operator ergonomics are considered in the design of dial indexing machines to provide easy access to workstations, reduce operator fatigue, and enhance safety.

- Automation Integration: Automation elements, such as robotic arms, vision systems, conveyor systems, and pick-and-place devices, can be integrated into dial indexing machines to further enhance precision and speed in the manufacturing and assembly processes.

- Packaging and Labeling: These machines can be configured to handle various packaging and labeling tasks, such as filling containers, applying caps, seals, labels, and arranging packaged products for distribution.

- Scalability: Consumer goods manufacturers can scale production by using multiple dial indexing machines or by integrating them into larger production lines.

Dial indexing machines are used in the consumer goods industry for a wide range of applications, including the assembly of electronics, the packaging of household appliances, and the processing of furniture components. They play a significant role in optimizing the manufacturing and assembly of consumer products, increasing production throughput, and maintaining quality and safety standards in the consumer goods manufacturing sector.