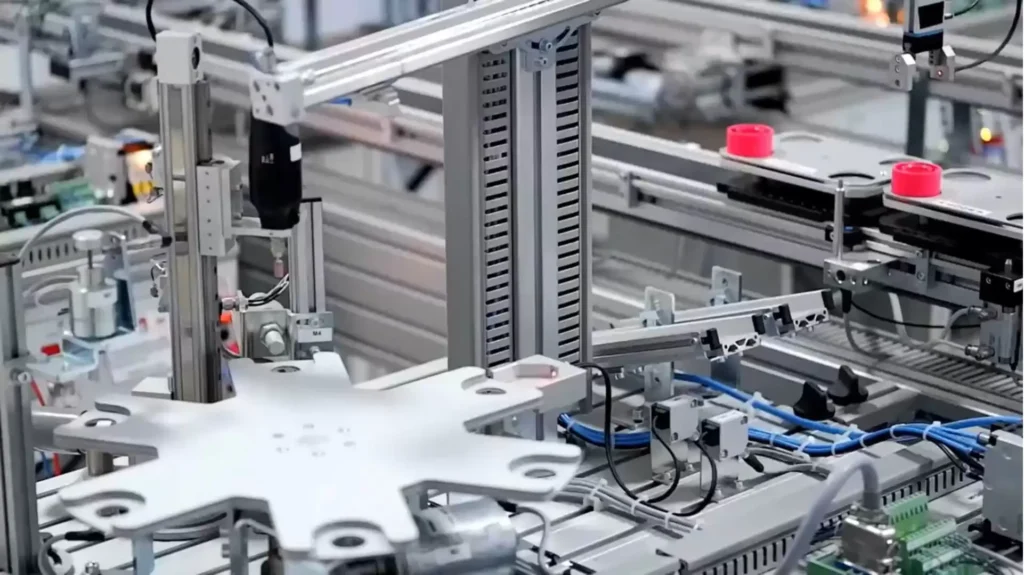

A dial-type assembly machine is a type of assembly machine that uses a rotating table, or dial, to transport workpieces from one station to the next. The dial is typically divided into multiple stations, each of which performs a specific task in the assembly process. The workpieces are loaded onto the dial at one station and then rotated to the next station, where the next task is performed. This process continues until the workpiece is complete, at which point it is unloaded from the dial.

Dial-type assembly machines are used in a wide variety of industries, including automotive, electronics, food and beverage, and consumer goods. They are particularly well-suited for assembling products that have a high number of components or that require a high degree of precision.

Dial-type assembly machines offer a number of advantages, including:

- Increased productivity: Dial-type assembly machines can help to increase productivity by reducing the time required to assemble products. This is because the machines can perform multiple tasks simultaneously and can also be used to assemble products in parallel.

- Improved quality: Dial-type assembly machines can help to improve the quality of assembled products by reducing the risk of errors. This is because the machines can be programmed to perform tasks consistently and accurately.

- Reduced costs: Dial-type assembly machines can help to reduce the costs associated with assembly by eliminating the need for manual labor. This can free up workers to perform other tasks or to focus on quality control.

- Increased safety: Dial-type assembly machines can help to improve safety by reducing the risk of accidents and injuries. This is because the machines can be programmed to perform tasks that would otherwise be hazardous for humans to perform.

Dial-type assembly machines can be automated to a high degree, using programmable logic controllers (PLCs), robots, and other automated equipment. This can help to further increase productivity, improve quality, and reduce costs.

Here are some examples of how dial-type assembly machines are used in industry:

- In the automotive industry, dial-type assembly machines are used to assemble car doors, dashboards, and other components.

- In the electronics industry, dial-type assembly machines are used to assemble circuit boards and other electronic devices.

- In the food and beverage industry, dial-type assembly machines are used to fill and seal containers, such as bottles, cans, and bags.

- In the consumer goods industry, dial-type assembly machines are used to assemble toys, appliances, and other products.

Dial-type assembly machines can be a valuable asset for businesses that need to assemble products quickly, accurately, and cost-effectively.

Additional applications of dial-type assembly machines:

- Medical device assembly

- Pharmaceutical packaging

- Cosmetic packaging

- Personal care product assembly

- Toy assembly

- Consumer electronics assembly

- Industrial product assembly

Benefits of using dial-type assembly machines:

- Increased productivity

- Improved quality

- Reduced costs

- Increased safety

- Flexibility

- Scalability

- Ergonomics

Dial-type assembly machines are a versatile and efficient way to assemble products. They can be used in a wide variety of industries and can be scaled to meet the needs of businesses of all sizes.

Medical Device Assembly

Medical device assembly is a critical process in the manufacturing of medical devices, ensuring that these devices are correctly and safely put together. This process involves several key components, including precision engineering, quality control, regulatory compliance, and the use of specialized materials. Here are some essential aspects of medical device assembly:

- Cleanroom Environments: Medical device assembly typically takes place in cleanroom environments to prevent contamination. Cleanrooms maintain strict environmental controls, including air quality, temperature, humidity, and particulate levels, to ensure the sterility of the devices.

- Quality Control: Stringent quality control procedures are essential to ensure that each device meets regulatory standards and is safe for use. This may involve various inspection and testing processes, such as visual inspection, leak testing, and functional testing.

- Material Selection: The materials used in medical device assembly must be biocompatible, non-toxic, and suitable for the device’s intended use. This includes selecting appropriate polymers, metals, adhesives, and coatings.

- Precision Assembly Techniques: Assembly processes must be highly precise, often involving microassembly techniques for intricate and small components. These methods include laser welding, ultrasonic welding, and adhesive bonding.

- Sterilization: Many medical devices must be sterilized after assembly to ensure they are free from harmful microorganisms. Common sterilization methods include gamma irradiation, ethylene oxide (EtO) gas sterilization, and steam autoclaving.

- Regulatory Compliance: The medical device industry is heavily regulated, and assembly processes must adhere to quality standards and regulations, such as those set by the FDA in the United States or the European Medicines Agency (EMA) in Europe.

- Documentation and Traceability: Comprehensive documentation and traceability are crucial for tracking the materials and processes used in each device’s assembly. This is necessary for quality control and compliance with regulatory requirements.

- Customization: Some medical devices are customized for specific patients or applications, which requires the ability to adapt the assembly process to individual requirements.

- Miniaturization: Many medical devices are becoming increasingly compact and miniaturized, requiring advanced assembly techniques and tools to handle small components.

- Electronics Integration: Some medical devices incorporate electronics and sensors. The assembly process may involve the integration of circuit boards and wiring, along with mechanical components.

- Adhesive Bonding: Adhesives play a crucial role in medical device assembly, used for joining components, sealing, and providing structural integrity. Choosing the right adhesive and employing proper bonding techniques is critical.

- Automation: In some cases, automated assembly processes are employed to increase efficiency, consistency, and precision. Robotics and specialized automation equipment can be used in these applications.

- Packaging: After assembly, medical devices are often packaged in sterile packaging that maintains their integrity and sterility until they are used.

Medical device assembly is a complex and highly regulated process that demands the utmost precision and quality. The successful assembly of medical devices ensures that they are safe, effective, and reliable for their intended medical applications. Manufacturers in this field must be well-versed in regulatory requirements and quality standards to ensure the safety and efficacy of their products.

Pharmaceutical Packaging

Pharmaceutical packaging is a critical component of the pharmaceutical industry, ensuring the safe storage, distribution, and dispensing of drugs and medical products. It serves several essential functions, including protection, information, and regulatory compliance. Here are some key aspects of pharmaceutical packaging:

- Product Protection: The primary role of pharmaceutical packaging is to protect drugs and medical products from external factors that can affect their quality and efficacy. This includes protection from moisture, light, oxygen, and contaminants.

- Safety and Tamper Resistance: Pharmaceutical packaging is designed to deter tampering and counterfeiting. Features such as tamper-evident seals, holograms, and unique identifiers help ensure product safety and authenticity.

- Compliance with Regulatory Standards: The pharmaceutical industry is highly regulated, and packaging must comply with local and international regulations. This includes labeling, safety warnings, and child-resistant packaging for certain products.

- Information and Labeling: Accurate and comprehensive labeling is essential to inform healthcare professionals and patients about the product’s proper use, dosage, side effects, and storage requirements.

- Child-Resistant Packaging: Some medications and medical products are required to be in child-resistant packaging to prevent accidental ingestion by children.

- Barrier Properties: Pharmaceutical packaging materials are selected for their barrier properties. For example, blister packs, vials, and ampoules provide effective barriers to moisture and oxygen.

- Unit Dose Packaging: Unit dose packaging, such as pre-filled syringes and blister packs, ensures that the correct dosage is easily administered. This is particularly important for patient safety and compliance.

- Serialization and Track-and-Trace: To combat counterfeiting and ensure product traceability, pharmaceutical packaging often includes unique serial numbers and barcodes for tracking products throughout the supply chain.

- Aseptic Packaging: For sterile products, aseptic packaging techniques and materials are used to maintain sterility during the product’s shelf life.

- Light-Sensitive Medications: Packaging for light-sensitive medications often includes opaque or amber-colored materials to protect the product from light exposure.

- Smart Packaging: Emerging technologies like RFID tags and smart packaging can provide real-time monitoring and tracking of pharmaceuticals in the supply chain, helping to prevent theft, counterfeiting, and ensure proper storage conditions.

- Sustainability: There is a growing emphasis on sustainable packaging in the pharmaceutical industry. Biodegradable materials, reduced packaging waste, and eco-friendly designs are becoming more prevalent.

- Pharmaceutical Storage: Some pharmaceutical packaging is designed for long-term storage, such as glass vials for vaccines and freeze-drying technology for biologics.

- User-Friendly Packaging: Ease of use is important for patients. Packaging may include features like easy-to-open containers, clear dosing instructions, and packaging that aids in administration.

- Cost-Effective Packaging: Pharmaceutical companies often seek cost-effective packaging solutions that maintain product quality and safety while minimizing production costs.

Pharmaceutical packaging is a highly specialized field that requires a deep understanding of materials, regulations, and the specific requirements of each product. Ensuring the quality and integrity of pharmaceutical packaging is essential to patient safety and the success of the pharmaceutical industry.

Cosmetic Packaging

Cosmetic packaging is an essential component of the cosmetics and beauty industry. It serves multiple functions, including product protection, branding, marketing, and regulatory compliance. Here are some key aspects of cosmetic packaging:

- Product Protection: Cosmetic packaging must protect the product from external factors that can affect its quality and safety. This includes protection from air, light, moisture, and contaminants to ensure the product remains effective and safe for use.

- Branding and Aesthetics: Packaging plays a critical role in branding and product differentiation. The design, color, shape, and material of the packaging are used to convey the brand’s identity and create a visual appeal that attracts consumers.

- Marketing and Promotion: Cosmetic packaging often includes elements that market the product, such as attractive labels, images, and information about the product’s benefits. Packaging can also include features that demonstrate the product’s use, such as a clear window to view the color of the product.

- User Experience: Ease of use is essential for cosmetic packaging. Packaging should be designed to facilitate easy application, dispensing, and storage of the product. Applicators and pumps, for example, are designed for precise and hygienic use.

- Sustainability: There is a growing trend toward sustainable and eco-friendly cosmetic packaging. This includes the use of recyclable materials, biodegradable options, and minimizing packaging waste.

- Regulatory Compliance: Cosmetic packaging must meet regulatory requirements related to labeling, ingredient lists, safety warnings, and more. Compliance with regional regulations is crucial to ensure the safety and transparency of the product.

- Protection of Fragile Products: Some cosmetics are fragile or sensitive to environmental factors. Packaging for these products may include airless pumps or vacuum-sealed containers to prevent exposure to air and contamination.

- Customization: Cosmetic companies often use various sizes and shapes of packaging to cater to different product lines and customer preferences. Custom packaging can also be designed to coincide with limited edition or seasonal products.

- Dispensing Mechanisms: Packaging for cosmetics often includes specialized dispensing mechanisms, such as droppers, pumps, spray nozzles, and twist-up tubes, depending on the product form and application method.

- Travel-Friendly Packaging: Travel-sized or portable packaging is designed for on-the-go convenience, allowing consumers to carry cosmetics in their bags without spillage or leakage.

- Tamper-Evident Packaging: For consumer safety, tamper-evident features like shrink bands, induction seals, and tear-off caps are employed to indicate if a product has been opened or tampered with.

- Clear Labels and Ingredients: Transparent labels and packaging may be used to showcase the product’s color or texture, while ingredient lists and usage instructions are often prominently displayed.

- Packaging Materials: Various materials are used for cosmetic packaging, including glass, plastic, metal, and sustainable options like bamboo or paper.

Cosmetic packaging is a dynamic field that combines aesthetics, functionality, and compliance. Creating attractive, user-friendly, and sustainable packaging is essential to compete in the cosmetics industry and meet consumer expectations.

Personal Care Product Assembly

Personal care product assembly involves the manufacturing and packaging of various personal care items such as cosmetics, skincare products, toiletries, and hygiene products. This process is essential to ensure that these products are correctly and safely put together, meeting quality, safety, and regulatory standards. Here are some key aspects of personal care product assembly:

- Product Formulation: Personal care products often involve the formulation of specific ingredients, including emollients, active ingredients, fragrances, and preservatives. The formulation process must ensure that the final product meets the intended purpose and quality standards.

- Quality Control: Stringent quality control measures are essential to ensure that each product meets safety and quality standards. Inspection and testing processes are carried out to check for contaminants, defects, and irregularities.

- Packaging Selection: The choice of packaging material and design is crucial in the assembly of personal care products. Packaging materials must be compatible with the product, preserving its quality and safety. Packaging should also be user-friendly and convey brand identity.

- Labeling and Regulatory Compliance: Personal care product assembly must adhere to labeling regulations, including ingredient lists, safety warnings, and usage instructions. Compliance with local and international regulations is crucial to ensure product safety and transparency.

- Sanitization and Sterilization: Personal care products are often used on the skin and hair, so maintaining a sterile environment during manufacturing and packaging is essential to prevent contamination. Sterilization methods, such as UV irradiation and filtration, may be used.

- Batching and Mixing: Personal care products may require the mixing and blending of ingredients in specific quantities and under controlled conditions to achieve the desired texture, consistency, and quality.

- Filling and Dispensing: The assembly process includes filling the product into its chosen packaging, whether it’s bottles, jars, tubes, or spray containers. Automated filling machines are often used to ensure accuracy and consistency.

- Customization: Personal care products may offer customized options such as personalized fragrances, color choices, or packaging styles to cater to individual preferences.

- Sustainability: The personal care industry is increasingly focusing on sustainable packaging and production methods. Biodegradable materials, reduced packaging waste, and eco-friendly designs are becoming more common.

- User Experience: Ease of use is vital for personal care product assembly. Packaging should be designed to facilitate easy application, dispensing, and storage of the product.

- Safety and Tamper Resistance: Personal care products are sometimes required to be in tamper-resistant packaging to ensure product safety and consumer confidence. Features like shrink bands or induction seals may be employed.

- Custom Labels and Branding: Personal care product assembly often includes branding elements such as custom labels, printed packaging materials, and attractive design to make the product stand out and attract consumers.

- Scent and Fragrance Integration: Some personal care products are formulated with specific scents or fragrances, which need to be integrated precisely to maintain the product’s quality and efficacy.

- Specialized Packaging Formats: Personal care products come in a variety of forms, including creams, lotions, gels, and sprays. Each form may require specialized packaging and assembly processes.

Personal care product assembly is a complex and highly regulated process that demands precision, quality, and adherence to safety and regulatory standards. Ensuring the quality and integrity of personal care products is crucial for consumer safety and satisfaction.

Toy Assembly

Toy assembly is the process of manufacturing and assembling various types of toys, ensuring that they are safe, functional, and ready for market distribution. Toy assembly encompasses a wide range of products, including action figures, board games, puzzles, dolls, and electronic toys. Here are some key aspects of toy assembly:

- Safety Compliance: Ensuring toy safety is paramount. Toy assembly must adhere to strict safety regulations, especially when producing toys for children. This includes considerations for small parts, non-toxic materials, and adherence to safety standards, such as ASTM F963 in the United States.

- Quality Control: Quality control measures are implemented throughout the assembly process to identify and address defects, ensuring that each toy meets safety and quality standards. This includes visual inspections and functional testing.

- Material Selection: The selection of materials is essential in toy assembly to ensure they are safe, durable, and suitable for their intended purpose. These materials can include plastics, metals, fabrics, and electronics components.

- Component Assembly: Toys often consist of multiple components that must be correctly assembled. This includes attaching limbs, adding accessories, and integrating electronic components.

- Electronics Integration: Many modern toys incorporate electronic components, such as sensors, lights, and sound modules. Assembling and integrating these electronics is a critical part of the process.

- Painting and Decoration: The assembly process may include painting, decoration, and detailing to give toys their final appearance. This includes techniques like screen printing, pad printing, and hand painting.

- Packaging: Once toys are assembled, they are typically packaged in attractive and informative packaging. Packaging design is a key element for marketing and selling toys.

- Customization: Some toys offer customization options, such as color choices, accessories, and personalization, to cater to individual preferences.

- Small Parts Management: Special attention is given to small parts to prevent choking hazards, especially in toys designed for young children. Toy assembly must ensure that small parts are securely attached and cannot be easily dislodged.

- Sustainability: The toy industry is increasingly focusing on sustainability by using eco-friendly materials and reducing packaging waste.

- Interactive Features: Some toys include interactive features, such as sensors, buttons, or touchscreens. The assembly process involves integrating these features and ensuring they function correctly.

- Product Testing: Product testing may include functionality tests, safety tests, and assessments of durability to ensure that toys withstand normal wear and tear.

- Age-Appropriate Design: Toy assembly must consider the age-appropriateness of the product, ensuring that the toy is safe and suitable for the intended age group.

- Labeling and Instruction Manuals: Toys are typically labeled with information such as age recommendations, safety warnings, and usage instructions. Instruction manuals may be included for complex toys.

- Tamper Resistance: Some toys may employ tamper-evident packaging to prevent unauthorized access and ensure consumer safety.

Toy assembly involves a combination of design, engineering, and manufacturing processes to create products that meet safety standards, fulfill consumer expectations, and offer play value. It is essential to maintain the quality, safety, and integrity of toys for children and consumers of all ages.

Consumer Electronics Assembly

Consumer electronics assembly is the process of manufacturing and assembling a wide range of electronic products that are designed for personal or household use. This includes devices such as smartphones, laptops, tablets, televisions, audio equipment, gaming consoles, and other electronic gadgets. Here are key aspects of consumer electronics assembly:

- Component Sourcing: The assembly process begins with the procurement of various electronic components, including microprocessors, memory chips, displays, sensors, and other hardware components. Many manufacturers source components globally to ensure availability and cost-effectiveness.

- PCB Assembly: Printed Circuit Board (PCB) assembly is a critical step where electronic components are mounted onto PCBs. Surface-mount technology (SMT) and through-hole technology (THT) are commonly used techniques for soldering components onto PCBs.

- Surface Mount Technology (SMT): SMT involves placing surface-mounted components directly onto the PCB and soldering them with reflow soldering ovens. This method is prevalent in modern electronics manufacturing.

- Through-Hole Technology (THT): THT involves inserting component leads through holes on the PCB and soldering them on the opposite side. While it’s less common in modern electronics, it’s still used for certain components.

- Testing and Quality Control: Rigorous testing is conducted at various stages of assembly, including automated optical inspection (AOI) and in-circuit testing (ICT) to identify and rectify defects.

- Customization: Some consumer electronics can be customized to meet individual customer preferences, allowing choices like colors, storage capacities, or other features.

- Enclosure Assembly: The housing or casing for the device is assembled, which may include plastic injection molding, metal fabrication, and joining various parts to create the final product enclosure.

- Display Integration: If the device features a display (e.g., LCD or OLED screen), it is integrated into the assembly, ensuring proper alignment and connectivity.

- Battery Integration: For devices that use batteries, battery packs are assembled and integrated, with safety measures in place to prevent overheating or malfunction.

- Electronics Testing: Comprehensive testing is conducted to ensure that the electronics and software are functioning correctly. This includes functional testing, connectivity tests, and software validation.

- Final Assembly: The electronic components are integrated into the product enclosure, and the final assembly is completed. This includes securing components, cable routing, and ensuring that all features are functioning as expected.

- Software Loading and Configuration: Devices that include firmware or software may have the necessary programs loaded onto them, and configurations are set according to the intended use or region.

- Quality Assurance: Rigorous quality assurance processes are carried out to confirm that every aspect of the product meets quality and performance standards.

- Packaging: Consumer electronics are packaged in a way that ensures product protection and facilitates distribution. Packaging design often plays a role in marketing and consumer appeal.

- User Manuals and Documentation: User manuals and documentation are included with the product to guide users on setup, operation, and maintenance.

- Regulatory Compliance: Consumer electronics must meet regulatory and safety standards, including electromagnetic compatibility (EMC), radio frequency compliance, and safety certifications.

- Recycling and Sustainability: Many electronics manufacturers aim to reduce their environmental impact by using eco-friendly materials, reducing packaging waste, and promoting recycling programs.

Consumer electronics assembly is a complex and highly regulated process, demanding precision and adherence to quality and safety standards. Ensuring the quality and safety of consumer electronics is essential for the satisfaction of consumers and compliance with global regulations.

Industrial Product Assembly

Industrial product assembly is a critical part of manufacturing various products and equipment used in industrial applications. These products can range from machinery and equipment for manufacturing and construction to specialized tools and instruments for industrial use. Here are key aspects of industrial product assembly:

- Component Sourcing: The assembly process begins with sourcing various components, including mechanical parts, electrical components, sensors, and other necessary materials. Many manufacturers procure components from suppliers worldwide to ensure quality and availability.

- Sub-Assembly: In complex industrial products, sub-assemblies are often prepared separately. These sub-assemblies may include motors, control panels, frames, and other components that are assembled individually before being integrated into the final product.

- Customization: Some industrial products can be customized to meet specific customer requirements. This includes options for power sources, dimensions, materials, and control systems, among others.

- Quality Control: Rigorous quality control is essential at various stages of assembly. Inspection processes, such as visual inspection, mechanical testing, and electrical testing, help identify and rectify defects.

- Welding and Fabrication: Industrial products often require welding and metal fabrication for frame construction and structural components.

- Electrical Integration: For products that include electrical or electronic components, such as control systems or sensors, assembly includes the integration of these elements and proper wiring.

- Testing and Calibration: Comprehensive testing and calibration are carried out to ensure that the product functions correctly. This may involve functional testing, performance testing, and calibration of sensors and control systems.

- Custom Wiring and Cable Routing: Proper cable routing and wiring are crucial for industrial products. Custom wiring may be required to accommodate specific applications or to meet industry standards.

- Final Assembly: All sub-assemblies and components are integrated into the product frame or housing to complete the final assembly.

- Software Loading and Configuration: Some industrial products, such as automated machinery or control systems, may require software loading and configuration to ensure proper operation.

- Hydraulic and Pneumatic Integration: Industrial products often involve the integration of hydraulic or pneumatic systems, such as cylinders, valves, and pumps.

- Documentation: Detailed assembly documentation, including user manuals, maintenance guides, and parts lists, is often provided with industrial products.

- Safety Features: Many industrial products include safety features such as emergency stops, safety interlocks, and protective guards to protect workers and equipment.

- Packaging: Industrial products are packaged to ensure protection during transport and handling, with consideration for the weight and size of the product.

- Regulatory Compliance: Industrial products must meet industry-specific standards and regulatory requirements, including safety, environmental compliance, and industry-specific certifications.

- User Training: Depending on the complexity of the product, manufacturers may offer user training to ensure safe and effective operation.

Industrial product assembly is a specialized and regulated process, requiring precision, quality control, and adherence to safety standards. The successful assembly of industrial products is crucial for their performance, reliability, and safety in industrial applications.