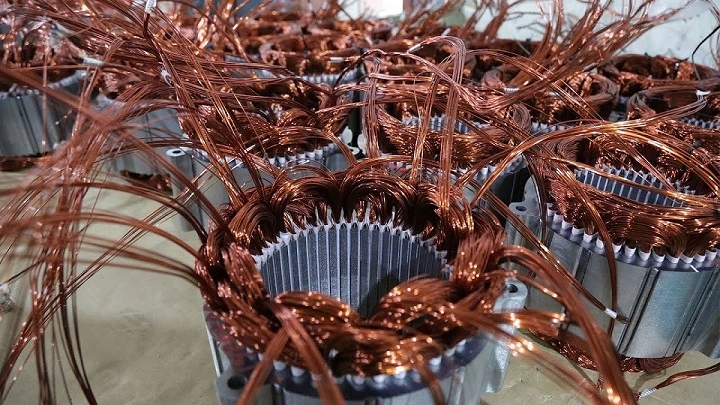

Winding machines for electric motor coils are used to wind the coils of electric motors. The coils are typically made of copper wire, which is wound around a bobbin or former. The bobbin or former is typically made of a material such as plastic, ceramic, or metal.

There are a variety of different types of winding machines for electric motor coils. Some of the most common types include:

- Hand-operated winding machines: Hand-operated winding machines are the simplest type of winding machine. They are typically used for small-scale production or for winding coils with complex designs.

- Semi-automatic winding machines: Semi-automatic winding machines use a combination of manual and automated steps. For example, the operator may load the wire onto the machine and then start the winding process. The machine will then automatically wind the coil and stop when it is finished.

- Automatic winding machines: Automatic winding machines are the most sophisticated type of winding machine. They can be programmed to wind coils of different sizes, shapes, and designs. Automatic winding machines are typically used for large-scale production.

Winding machines for electric motor coils are used in a variety of industries, including automotive, electronics, and industrial machinery. They are essential for the production of electric motors.

Here are some of the benefits of using winding machines for electric motor coils:

- Increased productivity: Winding machines for electric motor coils can help to increase productivity by reducing the time required to wind coils. This is because the machines can wind multiple coils simultaneously and can also be used to wind coils in parallel.

- Improved quality: Winding machines for electric motor coils can help to improve the quality of wound coils by reducing the risk of errors. This is because the machines can be programmed to wind coils consistently and accurately.

- Reduced costs: Winding machines for electric motor coils can help to reduce the costs associated with winding by eliminating the need for manual labor. This can free up workers to perform other tasks or to focus on quality control.

- Increased safety: Winding machines for electric motor coils can help to improve safety by reducing the risk of accidents and injuries. This is because the machines can be programmed to perform tasks that would otherwise be hazardous for humans to perform.

Overall, winding machines for electric motor coils are a valuable asset for businesses that need to wind coils quickly, accurately, and cost-effectively.