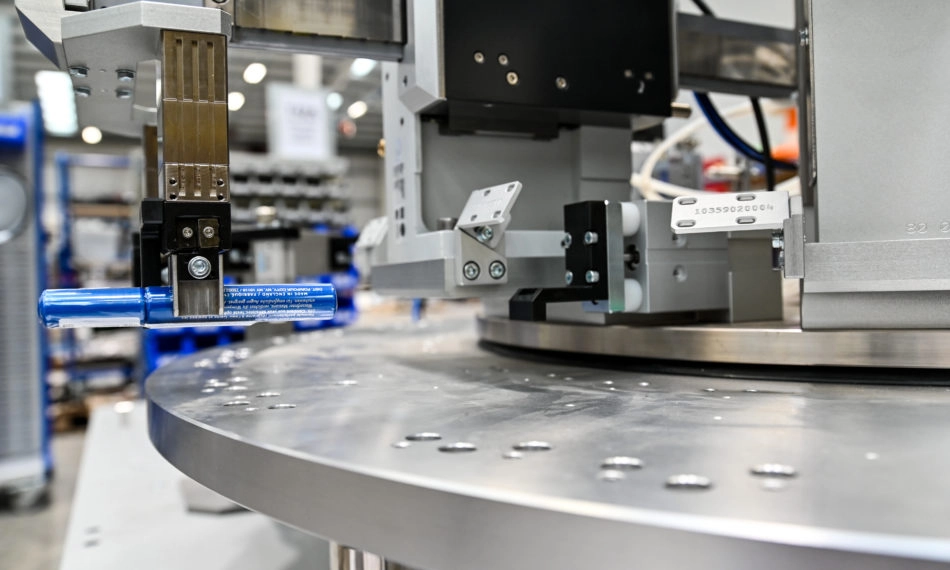

Rotary indexing table automation is the use of automated systems to control and operate rotary indexing tables. This can include using programmable logic controllers (PLCs), robots, and other automated equipment to perform tasks such as loading and unloading workpieces, performing assembly operations, and inspecting products.

Rotary Indexing Table Automation

Rotary assembly tables play a pivotal role in manufacturing and assembly processes, providing a dynamic solution to streamline workflow. These tables are designed with a rotating platform, allowing workers to access different sides of the assembly with ease. This rotational capability minimizes the need for workers to reposition themselves or the product during assembly.

The benefits of rotary assembly tables are multifaceted. First and foremost, they enhance efficiency by reducing downtime associated with manual repositioning. Workers can stay in one location while the table rotates, optimizing the assembly line’s overall productivity. This not only accelerates the assembly process but also contributes to a more ergonomic and comfortable working environment.

Additionally, rotary assembly tables are adaptable to various production needs. Their design allows for customization, accommodating different assembly sizes and complexities. This versatility makes them suitable for a wide range of industries, from electronics to automotive manufacturing.

Furthermore, these tables contribute to quality control efforts. With improved accessibility to all sides of the assembly, workers can more easily inspect and ensure the precision of each component. This can result in fewer errors and defects, ultimately enhancing the overall quality of the finished products.

In conclusion, rotary assembly tables represent a smart investment for manufacturers aiming to optimize their assembly processes. By combining efficiency, adaptability, and quality benefits, these tables contribute to creating a more streamlined and effective production line.

Rotary assembly tables find application across diverse industries due to their versatility and efficiency. Some prominent areas include:

- Manufacturing and Assembly Lines: The primary application is in manufacturing and assembly processes, where these tables streamline workflows, reduce downtime, and enhance overall efficiency.

- Electronics Industry: In the production of electronic devices, such as smartphones and computers, rotary assembly tables facilitate the intricate assembly of components and help ensure precision in manufacturing.

- Automotive Manufacturing: Rotary assembly tables are used in the automotive industry for assembling complex vehicle parts. They contribute to efficient and accurate assembly of components in the production of cars, trucks, and other vehicles.

- Aerospace Industry: In the aerospace sector, where precision and quality control are critical, rotary assembly tables aid in assembling intricate and specialized components for aircraft and spacecraft.

- Medical Device Manufacturing: These tables are valuable in the production of medical devices, where precision and accuracy are paramount. They contribute to the efficient assembly of complex medical equipment.

- Consumer Goods Production: Rotary assembly tables are employed in the production of various consumer goods, such as appliances and household items, streamlining the assembly of components.

- Packaging Industry: In packaging lines, these tables can be used to assemble and package products efficiently, improving the overall speed and accuracy of the packaging process.

- Textile Industry: Rotary assembly tables find application in textile manufacturing, aiding in the assembly of textile machinery components and ensuring precise construction.

- Pharmaceutical Industry: In pharmaceutical manufacturing, these tables can be used for assembling and packaging pharmaceutical products with a focus on accuracy and efficiency.

- General Manufacturing: From small-scale workshops to large-scale industrial facilities, rotary assembly tables are versatile tools that can adapt to a wide range of manufacturing needs, making them suitable for various general manufacturing applications.

In essence, the adaptability and efficiency of rotary assembly tables make them valuable assets in industries where precision assembly and workflow optimization are essential.

Rotary assembly tables play a crucial role in manufacturing and assembly lines by significantly improving efficiency and workflow. Here are key aspects of their application in these settings:

- Optimized Workflow: Rotary tables enable a continuous workflow as they allow workers to stay in one place while the table rotates, presenting different assembly points. This minimizes the need for workers to reposition themselves or the product, leading to a more streamlined and efficient assembly process.

- Reduced Downtime: The rotational feature of these tables reduces downtime associated with manual repositioning. Workers can seamlessly transition between assembly points, minimizing interruptions and enhancing overall productivity on the assembly line.

- Increased Productivity: By providing easy access to different sides of the assembly, rotary tables contribute to increased productivity. Workers can focus on their tasks without interruptions, resulting in faster assembly times and higher production output.

- Versatility and Adaptability: Rotary assembly tables are adaptable to various manufacturing needs. Their design allows for customization to accommodate different assembly sizes, complexities, and product types. This versatility makes them suitable for a wide range of industries and assembly line setups.

- Quality Assurance: The accessibility provided by these tables enhances quality control efforts. Workers can efficiently inspect and ensure the precision of each component, contributing to a reduction in errors and defects. This, in turn, improves the overall quality of the finished products.

- Ergonomic Benefits: These tables contribute to a more ergonomic working environment. Workers can perform their tasks with less physical strain since they don’t need to constantly reposition themselves. This can lead to improved employee well-being and potentially reduce the risk of work-related injuries.

- Adoption of Automation: In conjunction with automation technologies, rotary assembly tables can further enhance efficiency. Automated processes synchronized with the rotational movement can further reduce manual labor, allowing for a more efficient and cost-effective assembly line.

In summary, rotary assembly tables are integral components in manufacturing and assembly lines, providing a range of benefits that contribute to increased efficiency, reduced downtime, improved quality control, and enhanced overall productivity. Their adaptability makes them a valuable asset in various industries where assembly processes are critical to the production of goods.

In the electronics industry, rotary assembly tables are indispensable tools that contribute significantly to the efficiency and precision of manufacturing processes. Here are key aspects of their application in the electronics sector:

- Component Assembly: Rotary tables are used for the assembly of intricate electronic components, such as circuit boards and microchips. The rotating platform allows workers to access different sides of the assembly, facilitating the precise placement of components.

- PCB Assembly: In the production of printed circuit boards (PCBs), rotary assembly tables streamline the process. Workers can efficiently assemble and solder components onto the PCB without the need for constant repositioning, leading to faster and more accurate PCB assembly.

- Efficient Soldering: Soldering is a critical step in electronic assembly. Rotary tables enhance soldering processes by providing easy access to various soldering points. This contributes to the consistency and quality of soldered connections.

- Quality Control: The rotational capability of these tables aids in quality control inspections. Workers can inspect electronic assemblies from different angles, ensuring that components are correctly placed and soldered. This is crucial for maintaining high-quality standards in electronic manufacturing.

- Prototype Development: In research and development settings, rotary assembly tables are valuable for prototyping electronic devices. Engineers and technicians can iterate through design changes more efficiently, testing and assembling prototypes with ease.

- Small Parts Handling: The electronics industry often involves working with small and delicate components. Rotary tables provide a stable platform for handling these components, reducing the risk of damage during assembly.

- Adaptability to Different Products: The versatility of rotary tables allows for the assembly of various electronic products, from consumer electronics like smartphones and tablets to industrial equipment and specialized electronic devices.

- Integration with Automated Processes: In advanced manufacturing facilities, rotary assembly tables can be integrated with automated processes. This integration enhances the overall efficiency of electronic assembly lines by combining manual precision with automated speed.

- Ergonomics and Worker Comfort: The ergonomic design of rotary tables contributes to a more comfortable working environment for assembly line workers. This can improve overall job satisfaction and reduce the physical strain associated with intricate assembly tasks.

In conclusion, rotary assembly tables are essential in the electronics industry, providing a range of benefits from efficient assembly processes to improved quality control. Their adaptability makes them well-suited for the dynamic and intricate nature of electronic component assembly.

In the realm of medical device manufacturing, rotary assembly tables play a crucial role in enhancing precision, efficiency, and quality control. Here are key aspects of their application in the medical device industry:

- Precision Assembly: Medical devices often consist of intricate and precise components. Rotary assembly tables facilitate the accurate placement of components, ensuring that the assembly meets stringent quality and safety standards.

- Implantable Devices: For the production of implantable medical devices, such as pacemakers or prosthetics, rotary tables are invaluable. They enable workers to access different angles of the assembly, contributing to the meticulous assembly process required for these critical devices.

- Surgical Instruments: The assembly of surgical instruments demands precision and attention to detail. Rotary tables aid in the efficient assembly of surgical tools, ensuring that they meet the strict specifications required for medical procedures.

- Quality Assurance: The ability to rotate the assembly allows for thorough quality control inspections. Workers can inspect medical devices from various perspectives, verifying the correct placement of components and identifying any defects or irregularities.

- Customization for Diverse Devices: Medical device manufacturing often involves a wide range of products with varying complexities. Rotary assembly tables can be customized to accommodate the specific assembly needs of different medical devices, from diagnostic equipment to therapeutic devices.

- Cleanroom Applications: In environments requiring strict cleanliness standards, such as cleanrooms in medical manufacturing facilities, rotary tables can be designed to meet these requirements. This ensures that the assembly process is conducted in a controlled and sterile environment.

- Small-Scale Assembly: Some medical devices, particularly those used in minimally invasive procedures, may involve small-scale assembly. Rotary tables provide a stable platform for handling delicate components, contributing to the precision required for such devices.

- Workflow Optimization: By minimizing the need for workers to reposition themselves or the device during assembly, these tables contribute to an optimized workflow. This efficiency is particularly valuable in medical manufacturing, where accuracy and speed are paramount.

- Compliance with Regulatory Standards: Medical device manufacturing is subject to rigorous regulatory standards. The use of rotary assembly tables helps manufacturers comply with these standards by ensuring consistency, precision, and traceability in the assembly process.

- Ergonomics and Worker Safety: The ergonomic design of rotary tables enhances worker comfort and safety during the assembly of medical devices. This is crucial in environments where workers may be engaged in intricate and detailed tasks for extended periods.

In summary, rotary assembly tables are integral to the medical device manufacturing process, contributing to the production of high-quality, precise, and compliant medical devices that meet the stringent standards of the healthcare industry.

In consumer goods production, rotary assembly tables serve as valuable tools to enhance efficiency, speed up assembly processes, and contribute to the overall quality of finished products. Here’s how these tables are applied in the manufacturing of consumer goods:

- Efficient Product Assembly: Rotary tables allow workers to access different sides of a product during assembly without the need for constant repositioning. This streamlined workflow accelerates the assembly process for consumer goods, such as appliances, electronics, and household items.

- Multi-Station Assembly: The rotating platform enables multi-station assembly on a single table. This means that various components of a product can be assembled simultaneously, improving overall production speed.

- Versatility for Diverse Products: Consumer goods production often involves a wide range of products with varying sizes and complexities. Rotary assembly tables can be customized to accommodate different assembly requirements, making them versatile tools for diverse product lines.

- Quality Control Inspections: The ability to rotate products during assembly facilitates thorough quality control inspections. Workers can easily examine different aspects of the product, ensuring that components are correctly assembled and that the final product meets quality standards.

- Handling Small Parts: Many consumer goods involve the assembly of small and intricate parts. Rotary tables provide a stable and controlled platform for handling these components, minimizing the risk of errors and defects during assembly.

- Adaptation to Automated Processes: In modern manufacturing setups, rotary assembly tables can be integrated with automated processes. This integration optimizes efficiency by combining the precision of manual assembly with the speed of automated systems.

- Customizable Workstations: Manufacturers can design rotary assembly tables to meet the specific needs of their production lines. This includes considerations for ergonomics, product size, and assembly complexity, creating customized workstations for improved efficiency.

- Reduced Worker Fatigue: By minimizing the physical strain associated with repetitive movements and repositioning, rotary assembly tables contribute to a more ergonomic working environment. This can help reduce worker fatigue and improve overall well-being.

- Quick Changeovers: When producing different consumer goods on the same assembly line, quick changeovers are essential. Rotary tables facilitate this process by allowing workers to easily transition between product types without significant downtime.

- Increased Production Output: The efficiency gains achieved with rotary assembly tables contribute to increased production output. This is particularly beneficial in consumer goods manufacturing, where meeting market demand in a timely manner is crucial.

In conclusion, rotary assembly tables are instrumental in optimizing consumer goods production, providing manufacturers with the tools to enhance efficiency, maintain quality standards, and adapt to the dynamic nature of the consumer goods market.

In the packaging industry, rotary assembly tables serve as valuable assets to streamline packaging processes and enhance overall efficiency. Here are key aspects of their application in this industry:

- Product Sorting and Orientation: Rotary tables are used to facilitate the sorting and orientation of products before they are packaged. The rotating platform allows workers to easily access different sides of items, ensuring proper alignment and arrangement.

- Bottle and Container Filling: In industries such as food and beverage or pharmaceuticals, rotary assembly tables are employed for filling bottles and containers. The rotating platform aids in positioning containers accurately under filling nozzles, contributing to precision in the packaging process.

- Labeling and Printing: Rotary tables are utilized in labeling and printing processes. Products can be rotated to the appropriate position for labeling or printing, ensuring that labels are applied accurately and information is printed in the correct orientation.

- Quality Control Checks: The ability to rotate products allows for efficient quality control inspections. Workers can inspect packaged items from various angles to ensure that they meet quality standards and that the packaging is secure.

- Kitting and Assembly: For products that require multiple components or pieces to be assembled before packaging, rotary tables enable workers to access different assembly points without unnecessary movement. This contributes to the efficiency of kitting and assembly processes.

- Integration with Conveyor Systems: Rotary assembly tables can be seamlessly integrated into conveyor systems, allowing for a continuous flow of products through the packaging line. This integration optimizes the overall speed and efficiency of the packaging process.

- Adaptability to Different Product Sizes: Packaging lines often handle products of various sizes and shapes. Rotary tables can be customized to accommodate different product dimensions, providing flexibility in packaging different items on the same assembly line.

- Packing and Cartoning: In packing and cartoning processes, rotary tables aid in the efficient placement of products into packaging materials. The rotating platform allows workers to access different sides of the product, ensuring proper placement within the packaging.

- Reduced Downtime: By eliminating the need for workers to constantly reposition themselves or products, rotary tables contribute to reduced downtime in the packaging line. This results in a more continuous and efficient workflow.

- Improved Ergonomics: The ergonomic design of rotary tables reduces physical strain on workers by minimizing repetitive movements. This is especially important in the packaging industry, where workers may be involved in repetitive tasks for extended periods.

In summary, rotary assembly tables are essential components in the packaging industry, offering benefits such as improved efficiency, enhanced quality control, and adaptability to diverse packaging requirements. Their integration into packaging lines contributes to the overall optimization of the packaging process.

In the pharmaceutical industry, rotary assembly tables play a critical role in ensuring the precision, efficiency, and compliance necessary for the production of pharmaceutical products. Here are key aspects of their application in this industry:

- Precise Medication Assembly: Rotary tables aid in the precise assembly of pharmaceutical products, including medications and medical devices. The rotating platform allows workers to access different sides of the assembly, ensuring accurate placement of components.

- Packaging Medications: In the packaging of medications, especially in blister packs or vials, rotary assembly tables contribute to the efficient placement of medications into packaging materials. The rotating platform facilitates access to various points during the packaging process.

- Quality Control Inspections: The ability to rotate pharmaceutical products during assembly and packaging facilitates thorough quality control inspections. Workers can inspect products from different angles, ensuring that medications meet stringent quality and safety standards.

- Handling Delicate Components: Many pharmaceutical products involve handling delicate and sensitive components. Rotary tables provide a stable platform for the assembly of these components, minimizing the risk of damage during the manufacturing process.

- Customization for Different Medications: Pharmaceutical manufacturers often produce a variety of medications with different assembly requirements. Rotary assembly tables can be customized to accommodate the specific needs of different medications, ensuring flexibility in production.

- Integration with Cleanroom Environments: In environments requiring strict cleanliness standards, such as cleanrooms in pharmaceutical manufacturing, rotary tables can be designed to meet these requirements. This ensures that the assembly process is conducted in a controlled and sterile environment.

- Diverse Product Forms: The pharmaceutical industry produces medications in various forms, such as tablets, capsules, and liquid formulations. Rotary tables can be adapted to handle the unique requirements of assembling and packaging different product forms.

- Reduced Risk of Contamination: The controlled rotation of products during assembly and packaging minimizes the need for excessive handling. This, in turn, reduces the risk of contamination, a critical consideration in the pharmaceutical industry where product purity is paramount.

- Batch Processing: For pharmaceutical manufacturers dealing with batch production, rotary tables facilitate efficient batch processing. Workers can assemble and package multiple units simultaneously, contributing to batch consistency and speed.

- Compliance with Regulatory Standards: The pharmaceutical industry is highly regulated, and adherence to strict standards is essential. The use of rotary assembly tables helps manufacturers comply with these standards by ensuring consistency, precision, and traceability in the assembly process.

In summary, rotary assembly tables are integral to pharmaceutical manufacturing, providing the tools needed to maintain high levels of precision, efficiency, and compliance with regulatory requirements in the production of medications and medical devices.

Automatic rotary tables offer a number of advantages over traditional rotary tables, including:

- Increased productivity: Automatic rotary tables can help to increase productivity by reducing the time required to assemble and process products. This is because the machines can perform multiple tasks simultaneously and can also be used to assemble and process products in parallel.

- Improved quality: Automatic rotary tables can help to improve the quality of assembled and processed products by reducing the risk of errors. This is because the machines can be programmed to perform tasks consistently and accurately.

- Reduced costs: Automatic rotary tables can help to reduce the costs associated with assembly and manufacturing by eliminating the need for manual labor. This can free up workers to perform other tasks or to focus on quality control.

- Increased safety: Automatic rotary tables can help to improve safety by reducing the risk of accidents and injuries. This is because the machines can be programmed to perform tasks that would otherwise be hazardous for humans to perform.

Automatic rotary tables are used in a wide variety of industries, including automotive, electronics, food and beverage, and consumer goods. They are particularly well-suited for assembling and processing products that have a high number of components or that require a high degree of precision.

Here are some examples of how automatic rotary tables are used in industry:

- In the automotive industry, automatic rotary tables are used to assemble car doors, dashboards, and other components.

- In the electronics industry, automatic rotary tables are used to assemble circuit boards and other electronic devices.

- In the food and beverage industry, automatic rotary tables are used to fill and seal containers, such as bottles, cans, and bags.

- In the consumer goods industry, automatic rotary tables are used to assemble toys, appliances, and other products.

Automatic rotary tables can be a valuable asset for businesses that need to assemble and process products quickly, accurately, and cost-effectively.

Rotary indexing table automation can offer a number of benefits, including:

- Increased productivity: Rotary indexing table automation can help to increase productivity by reducing the time required to assemble products. This is because the machines can perform multiple tasks simultaneously and can also be used to assemble products in parallel.

- Improved quality: Rotary indexing table automation can help to improve the quality of assembled products by reducing the risk of errors. This is because the machines can be programmed to perform tasks consistently and accurately.

- Reduced costs: Rotary indexing table automation can help to reduce the costs associated with assembly by eliminating the need for manual labor. This can free up workers to perform other tasks or to focus on quality control.

- Increased safety: Rotary indexing table automation can help to improve safety by reducing the risk of accidents and injuries. This is because the machines can be programmed to perform tasks that would otherwise be hazardous for humans to perform.

Rotary indexing table automation can be used to automate a wide variety of assembly and manufacturing processes, including:

- Automotive assembly

- Electronics assembly

- Food and beverage packaging

- Medical device assembly

- Consumer goods assembly

There are a number of different ways to automate rotary indexing tables. One common approach is to use a PLC to control the table and any associated equipment. The PLC can be programmed to perform a variety of tasks, such as:

- Indexing the table to the next station

- Activating and deactivating actuators and other devices

- Controlling the flow of materials

- Monitoring the process for errors

Another approach to automating rotary indexing tables is to use robots. Robots can be used to perform tasks such as loading and unloading workpieces, performing assembly operations, and inspecting products. Robots can also be used to index the table to the next station.

The best approach to automating a rotary indexing table will depend on the specific needs of the business and the application. It is important to carefully consider the requirements of the process and the budget available before implementing an automation solution.

Here are some examples of rotary indexing table automation:

- An automotive assembly line that uses a rotary indexing table to assemble car doors. The table is divided into multiple stations, each of which performs a specific task in the assembly process, such as welding, painting, and installing components.

- An electronics assembly line that uses a rotary indexing table to assemble circuit boards. The table is divided into multiple stations, each of which performs a specific task in the assembly process, such as placing components, soldering, and testing the circuit boards.

- A food and beverage packaging line that uses a rotary indexing table to fill and seal containers. The table is divided into multiple stations, each of which performs a specific task in the packaging process, such as filling the containers, sealing the containers, and inspecting the containers.

Rotary indexing table automation can be a valuable way to improve the efficiency, quality, and safety of assembly and manufacturing processes.

Rotary Indexing Table Automation

Rotary indexing table automation refers to the process of integrating automatic and computer-controlled systems with rotary indexing tables to enhance manufacturing and assembly processes. Rotary indexing tables are mechanical devices that provide controlled, precise rotary motion and are used in various industries for tasks such as machining, assembly, testing, inspection, and more. Automation enhances the capabilities and efficiency of rotary indexing tables by reducing manual intervention, increasing precision, and enabling complex, repetitive tasks to be performed with accuracy. Here are key aspects of rotary indexing table automation:

- Automation Components: Rotary indexing table automation can involve the integration of various automation components, including robotic arms, conveyor systems, vision systems, sensors, and programmable logic controllers (PLCs).

- High Precision: Automation systems enhance the precision of rotary indexing tables, ensuring that components or workpieces are accurately positioned and aligned during the manufacturing or assembly process.

- Speed and Efficiency: Automated systems can significantly increase production speed and efficiency by reducing cycle times and enabling continuous, uninterrupted operation.

- Multi-Tasking: Automation allows rotary indexing tables to perform multiple tasks at different workstations around the table, such as assembly, inspection, labeling, and packaging, in a coordinated and synchronized manner.

- Quality Control: Automated systems often include quality control measures, such as vision inspection systems and sensors, to check for defects and ensure that components or products meet the required quality standards.

- Customization: Rotary indexing table automation is highly customizable and can be tailored to meet specific manufacturing requirements, such as those in the automotive, electronics, or consumer goods industries.

- Integration with Manufacturing Lines: Automated rotary indexing tables are often integrated into larger manufacturing lines, allowing for seamless coordination with other production equipment and processes.

- Operator Interface: Many automation systems feature user-friendly operator interfaces that allow for easy programming, monitoring, and control of the rotary indexing table and associated processes.

- Maintenance and Diagnostics: Automation systems may include diagnostics and maintenance features to monitor the health and performance of the equipment, helping to reduce downtime and ensure reliable operation.

- Safety Measures: Safety is a crucial aspect of rotary indexing table automation. Systems are designed to meet safety standards and may include features such as safety interlocks and emergency stop controls.

- Reduction in Manual Labor: Automation reduces the need for manual labor in repetitive and physically demanding tasks, which can lead to cost savings and improved worker safety.

- Flexibility: Automated rotary indexing tables can be reconfigured and adapted for different tasks and products, making them versatile for various industries.

Rotary indexing table automation is widely used in industries where precision, speed, and efficiency are essential, such as automotive manufacturing, electronics assembly, and consumer goods production. It plays a pivotal role in modern manufacturing, streamlining processes, improving product quality, and increasing overall productivity.

Automation Components

Automation components are essential elements and devices that are used to automate various industrial and manufacturing processes. These components play a crucial role in creating automated systems that enhance efficiency, productivity, and precision in industries such as manufacturing, automotive, electronics, and more. Here are some common automation components:

- Sensors: Sensors are devices that detect changes in the environment and provide input to control systems. Common types include proximity sensors, photoelectric sensors, ultrasonic sensors, and temperature sensors.

- Actuators: Actuators are devices that convert control signals into physical actions. Electric, pneumatic, and hydraulic actuators are used to move, position, or control machinery and equipment.

- Programmable Logic Controllers (PLCs): PLCs are industrial computers that control and automate various processes. They receive input from sensors and make decisions based on programmed logic, sending output signals to actuators.

- Human-Machine Interface (HMI): HMIs are devices that allow human operators to interact with and monitor automated systems. These devices often include touchscreens, displays, and controls.

- Industrial Robots: Industrial robots are programmable machines designed to perform tasks autonomously or under human control. They are commonly used for tasks like welding, painting, material handling, and assembly.

- Conveyor Systems: Conveyor systems are used to transport materials or products from one point to another within a production facility. They can be equipped with sensors and controls for automation.

- Vision Systems: Vision systems use cameras and image processing software to inspect, measure, and identify objects in industrial applications. They are crucial for quality control and inspection tasks.

- Motion Control Systems: Motion control components, such as servo motors and drives, are used to precisely control the movement of machinery and equipment in industrial automation.

- Industrial Networks: Industrial Ethernet and fieldbus networks are used for communication between automation components, allowing data exchange and control signals.

- Motion Sensors: These sensors detect the motion or position of objects or machinery. Examples include encoders and rotary sensors.

- Barcode and RFID Systems: Barcode scanners and RFID (Radio-Frequency Identification) systems are used for tracking and identifying products and components in manufacturing and logistics.

- Pneumatic Components: Pneumatic components, like pneumatic cylinders, valves, and actuators, use compressed air to control and move machinery and equipment.

- Hydraulic Components: Hydraulic components, such as hydraulic cylinders, pumps, and valves, use pressurized hydraulic fluid for controlling heavy machinery.

- Control Software: Software is a critical component for programming and controlling automation systems, including PLC programming, robotics control software, and HMI software.

- Safety Systems: Safety components, like emergency stop buttons, light curtains, and safety interlocks, are integrated into automation systems to ensure the safety of operators and protect against accidents.

- Linear Motion Components: Linear motion components, including linear guides, ball screws, and linear actuators, are used to create controlled linear movement in automation systems.

- Electrical Control Panels: Control panels house the electrical and electronic components used in automation systems. They are used to distribute power, control signals, and data.

Automation components can be integrated and customized to meet the specific needs of different industries and applications. They are fundamental in achieving greater efficiency, productivity, and quality in modern manufacturing and industrial processes.

High Precision

High precision refers to the degree of accuracy and exactness with which a measurement, process, or system can perform a task or produce results. Precision is a critical factor in various fields, including manufacturing, engineering, science, and technology. Achieving high precision is essential for ensuring the quality and reliability of products and processes. Here are some key aspects and considerations related to high precision:

- Accuracy: Precision is closely related to accuracy but is not the same. Accuracy refers to how close a measurement or result is to the true or target value. Precision, on the other hand, relates to the consistency and repeatability of measurements or results, regardless of their accuracy.

- Measurement: In measurement, high precision means that the measurements taken are consistently very close to each other. A precise measurement has minimal variation, and repeated measurements produce nearly identical results.

- Tolerance: In manufacturing and engineering, high precision is essential when tight tolerances are required. Tolerance specifies the allowable deviation or range within which a component or product must meet its design specifications.

- Instrumentation: High-precision instruments and equipment are designed to minimize errors and provide accurate and consistent measurements or results. Examples include precision measuring tools, high-precision scales, and precision machining equipment.

- Quality Control: Precision is a fundamental aspect of quality control in manufacturing. Ensuring that components or products are produced with high precision is crucial for maintaining quality standards and preventing defects.

- Repeatability: High precision implies that a process or measurement can be repeated multiple times with very little variation. Repeatability is a key characteristic of precision.

- Calibration: Calibrating instruments and equipment is essential to maintain and verify their precision. Calibration ensures that measurements are accurate and consistent over time.

- Micrometers: Micrometers are commonly used precision measuring instruments that can measure dimensions with very high accuracy and precision, often to the nearest thousandth of a millimeter (micron).

- Precision Machining: In manufacturing, precision machining processes such as CNC (Computer Numerical Control) machining and grinding are used to create components with high precision and tight tolerances.

- Precision Engineering: Precision engineering involves the design and production of components and systems with a high degree of precision. This is particularly important in industries like aerospace and medical device manufacturing.

- Scientific Research: In scientific experiments and research, high precision is crucial for obtaining accurate and reliable data. Precision measurements are often used in fields like physics, chemistry, and biology.

- Statistical Process Control: Statistical process control (SPC) is used in manufacturing to monitor and maintain high precision by analyzing process data and making adjustments to keep the process within specified limits.

- Environmental Factors: Environmental conditions, such as temperature and humidity, can impact precision. High-precision instruments and processes may need controlled environments to ensure consistent results.

- Risk Reduction: High precision reduces the risk of errors and inconsistencies in manufacturing and measurement processes, which can lead to costly defects and quality issues.

In summary, high precision is vital in various applications, from manufacturing and engineering to scientific research and quality control. It involves achieving consistent and accurate results and is essential for ensuring product quality, process reliability, and scientific integrity.