Pharmaceutical production is the process of manufacturing pharmaceutical drugs. It is a complex and highly regulated process that involves a number of steps, including:

1. Research and development: The first step in pharmaceutical production is to develop a new drug. This involves identifying a new target molecule, designing a drug that can interact with that molecule, and testing the drug in preclinical and clinical trials.

2. Formulation: Once a drug has been shown to be safe and effective in clinical trials, it needs to be formulated into a dosage form that can be administered to patients. This involves selecting the right excipients and developing a manufacturing process that can produce a consistent and stable product.

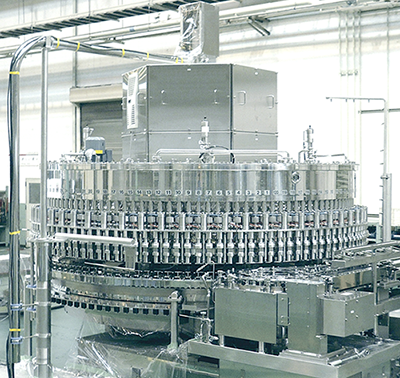

3. Manufacturing: The manufacturing process for pharmaceutical drugs can vary depending on the type of drug and the dosage form. However, most manufacturing processes involve a number of steps, such as blending, granulation, milling, coating, tablet pressing, filling, and packaging.

4. Quality control: Pharmaceutical drugs are subject to strict quality control standards. This is to ensure that the drugs are safe and effective for patients. Quality control is performed at all stages of the manufacturing process, from the raw materials to the finished product.

5. Regulatory approval: Before a new pharmaceutical drug can be marketed, it must be approved by a regulatory agency such as the US Food and Drug Administration (FDA). The regulatory agency will review the data from the preclinical and clinical trials to ensure that the drug is safe and effective.

Once a pharmaceutical drug has been approved by a regulatory agency, it can be marketed and sold to patients.

Here are some of the latest trends in pharmaceutical production:

- Continuous manufacturing: Continuous manufacturing is a new approach to pharmaceutical manufacturing that offers a number of advantages over traditional batch manufacturing. Continuous manufacturing can reduce waste, improve efficiency, and make it easier to scale up production.

- 3D printing: 3D printing is another new technology that is being used in pharmaceutical production. 3D printing can be used to create personalized dosage forms, such as pills that are tailored to the individual needs of a patient.

- Artificial intelligence (AI): AI is also being used in pharmaceutical production to improve efficiency and quality control. For example, AI can be used to automate tasks such as data analysis and image recognition.

Pharmaceutical production is a vital part of the healthcare system. It ensures that patients have access to safe and effective medicines.