Food and beverage packaging system automation is the use of robots and other automated systems to perform tasks in the packaging of food and beverage products. This can include tasks such as:

- Rinsing and filling: Automated systems can rinse and fill bottles, cans, and other food and beverage containers with precision and accuracy.

- Capping and sealing: Automated systems can cap and seal food and beverage containers with a variety of closures, such as screw caps, crown caps, and aluminum foil lids.

- Labeling: Automated systems can apply labels to food and beverage containers quickly and accurately.

- Case packing: Automated systems can pack food and beverage containers into cases, such as cardboard boxes and plastic crates.

- Palletizing: Automated systems can palletize cases of food and beverage containers onto pallets, ready for shipping.

Food and beverage packaging system automation offers a number of benefits, including:

- Improved quality: Automated systems can help to improve the quality of food and beverage packaging by ensuring that products are packaged consistently and to precise specifications. This can help to reduce the risk of product contamination and spoilage, and improve food safety.

- Increased productivity: Automated systems can help to increase productivity by performing tasks more quickly and efficiently than human workers. This can lead to increased output and profitability.

- Reduced costs: Automated systems can help to reduce costs by eliminating the need for manual labor and reducing waste.

- Improved safety: Automated systems can help to improve safety by reducing the exposure of workers to hazardous materials and equipment.

Food and beverage packaging system automation is used in a wide variety of food and beverage applications, including:

- Meat: Automated systems are used to package meat products, such as beef, pork, and chicken, in a variety of formats, such as trays, vacuum-sealed pouches, and cans.

- Poultry: Automated systems are used to package poultry products, such as chicken and turkey, in a variety of formats, such as trays, vacuum-sealed pouches, and bags.

- Seafood: Automated systems are used to package seafood products, such as fish and shrimp, in a variety of formats, such as trays, vacuum-sealed pouches, and bags.

- Fruits and vegetables: Automated systems are used to package fruits and vegetables in a variety of formats, such as bags, clamshells, and boxes.

- Dairy products: Automated systems are used to package dairy products, such as milk, cheese, and yogurt, in a variety of formats, such as bottles, cartons, and cups.

- Baked goods: Automated systems are used to package baked goods, such as bread, cookies, and cakes, in a variety of formats, such as bags, boxes, and trays.

- Beverages: Automated systems are used to package beverages, such as carbonated soft drinks, beer, wine, and spirits, in a variety of formats, such as bottles, cans, and kegs.

Here are some examples of automated systems used in food and beverage packaging:

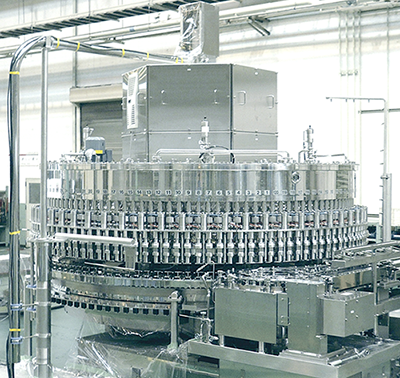

- Filling machines: Filling machines can fill food and beverage containers with precision and accuracy.

- Capping machines: Capping machines can cap food and beverage containers with a variety of closures.

- Labeling machines: Labeling machines can apply labels to food and beverage containers quickly and accurately.

- Case packers: Case packers can pack food and beverage containers into cases, such as cardboard boxes and plastic crates.

- Palletizers: Palletizers can palletize cases of food and beverage containers onto pallets, ready for shipping.

Food and beverage packaging system automation is playing an increasingly important role in the food and beverage industry. By automating tasks, food and beverage packaging system automation can help companies to improve quality, increase productivity, reduce costs, and improve safety.

Here are some of the latest trends in food and beverage packaging system automation:

- The use of collaborative robots: Collaborative robots, also known as cobots, are robots that are designed to work safely alongside human workers. Cobots are being used in food and beverage packaging system automation to perform tasks such as loading and unloading machines and packing products.

- The use of artificial intelligence (AI): AI is being used to develop food and beverage packaging system automation systems that can learn and adapt to changing conditions. This is making food and beverage packaging system automation systems more flexible and versatile, and better suited for a variety of applications.

- The use of cloud computing: Cloud computing is being used to make food and beverage packaging system automation systems more accessible and affordable for companies of all sizes

Beverage packaging system automation is the use of robots and other automated systems to perform tasks in the packaging of beverages. This can include tasks such as:

- Rinsing and filling: Automated systems can rinse and fill bottles, cans, and other beverage containers with precision and accuracy.

- Capping and sealing: Automated systems can cap and seal beverage containers with a variety of closures, such as screw caps, crown caps, and aluminum foil lids.

- Labeling: Automated systems can apply labels to beverage containers quickly and accurately.

- Case packing: Automated systems can pack beverage containers into cases, such as cardboard boxes and plastic crates.

- Palletizing: Automated systems can palletize cases of beverage containers onto pallets, ready for shipping.

Beverage packaging system automation offers a number of benefits, including:

- Improved quality: Automated systems can help to improve the quality of beverage packaging by ensuring that products are packaged consistently and to precise specifications. This can help to reduce the risk of product recalls and improve customer satisfaction.

- Increased productivity: Automated systems can help to increase productivity by performing tasks more quickly and efficiently than human workers. This can lead to increased output and profitability.

- Reduced costs: Automated systems can help to reduce costs by eliminating the need for manual labor and reducing waste.

- Improved safety: Automated systems can help to improve safety by reducing the exposure of workers to hazardous materials and equipment.

Beverage packaging system automation is used in a variety of beverage applications, including:

- Carbonated soft drinks: Automated systems are used to package carbonated soft drinks, such as cola and soda.

- Beer: Automated systems are used to package beer in bottles, cans, and kegs.

- Wine: Automated systems are used to package wine in bottles and boxes.

- Spirits: Automated systems are used to package spirits, such as whiskey, vodka, and rum, in bottles.

- Water: Automated systems are used to package water in bottles and jugs.

Here are some examples of automated systems used in beverage packaging:

- Filling machines: Filling machines can fill beverage containers with precision and accuracy.

- Capping machines: Capping machines can cap beverage containers with a variety of closures.

- Labeling machines: Labeling machines can apply labels to beverage containers quickly and accurately.

- Case packers: Case packers can pack beverage containers into cases, such as cardboard boxes and plastic crates.

- Palletizers: Palletizers can palletize cases of beverage containers onto pallets, ready for shipping.

Beverage packaging system automation is playing an increasingly important role in the beverage industry. By automating tasks, beverage packaging system automation can help companies to improve quality, increase productivity, reduce costs, and improve safety.

Here are some of the latest trends in beverage packaging system automation:

- The use of collaborative robots: Collaborative robots, also known as cobots, are robots that are designed to work safely alongside human workers. Cobots are being used in beverage packaging system automation to perform tasks such as loading and unloading machines and packing products.

- The use of artificial intelligence (AI): AI is being used to develop beverage packaging system automation systems that can learn and adapt to changing conditions. This is making beverage packaging system automation systems more flexible and versatile, and better suited for a variety of applications.

- The use of cloud computing: Cloud computing is being used to make beverage packaging system automation systems more accessible and affordable for companies of all sizes. Cloud computing allows companies to access powerful beverage packaging system automation systems without having to invest in their own hardware and infrastructure.

Beverage packaging system automation is a rapidly evolving field. New technologies and applications are being developed all the time. Beverage packaging system automation is playing an increasingly important role in helping companies to produce high-quality beverage products efficiently and cost-effectively.