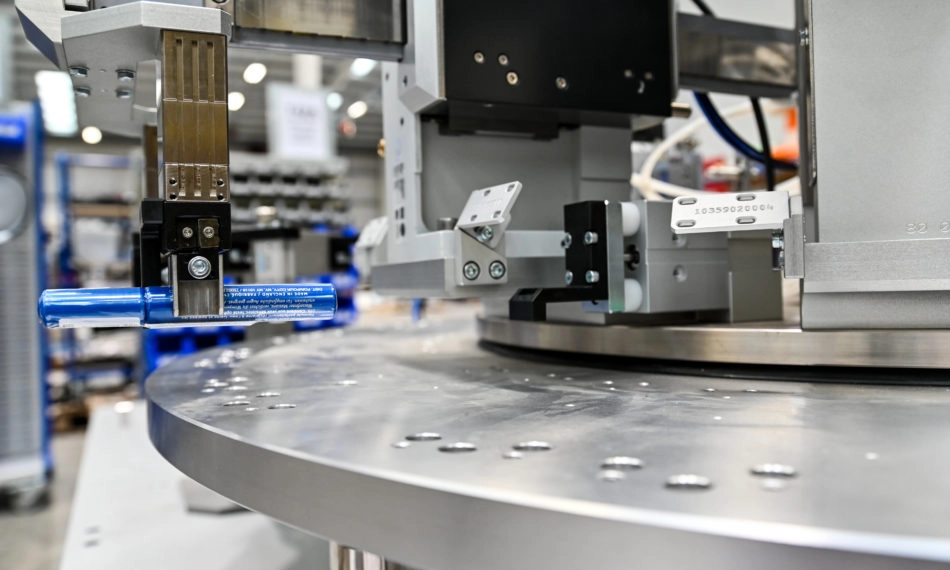

Battery assembly lines are automated systems that assemble battery packs from individual battery cells. The process typically involves the following steps:

- Cell preparation: The battery cells are cleaned and inspected to ensure that they are free of defects and meet the required specifications.

- Cell sorting: The battery cells are sorted based on their voltage, capacity, and other characteristics. This ensures that the battery packs are assembled with cells that are evenly matched, which improves the performance and lifespan of the battery.

- Cell welding: The battery cells are welded together to form the battery pack. The welding process must be done carefully to avoid damaging the cells or creating a fire hazard.

- Battery pack assembly: The battery pack is assembled by connecting the battery cells to the terminals and other components. This is typically done using a robotic arm.

- Battery pack testing: The battery pack is tested to ensure that it is functioning properly and meets the required specifications.

Battery assembly lines can be manual, semi-automated, or fully automated. Manual battery assembly lines are typically used for small-scale production or for assembling batteries with complex designs. Semi-automated battery assembly lines use automated equipment to perform some of the tasks, such as cell sorting and welding. Fully automated battery assembly lines use automated equipment to perform all of the tasks involved in the assembly process.

Cell preparation in Battery Assembly Lines

Cell preparation is the first step in the battery assembly process. It involves cleaning and inspecting the battery cells to ensure that they are free of defects and meet the required specifications.

The following are some of the key steps involved in cell preparation:

- Cleaning: The battery cells are cleaned to remove any dirt, dust, or other contaminants. This is typically done using a solvent or a cleaning machine.

- Inspection: The battery cells are inspected to identify any defects, such as cracks, dents, or corrosion. This can be done visually or using automated inspection equipment.

- Sorting: The battery cells are sorted based on their voltage, capacity, and other characteristics. This ensures that the battery packs are assembled with cells that are evenly matched, which improves the performance and lifespan of the battery.

Cell preparation is an important step in the battery assembly process, as it helps to ensure that the batteries are of high quality and will perform reliably.

Here are some of the benefits of proper cell preparation:

- Improved battery performance and lifespan

- Reduced risk of battery failure

- Increased safety of battery packs

- Reduced costs associated with battery defects

Proper cell preparation is essential for the production of high-quality battery packs. It is important to have a well-defined cell preparation process in place and to use the appropriate equipment and materials.