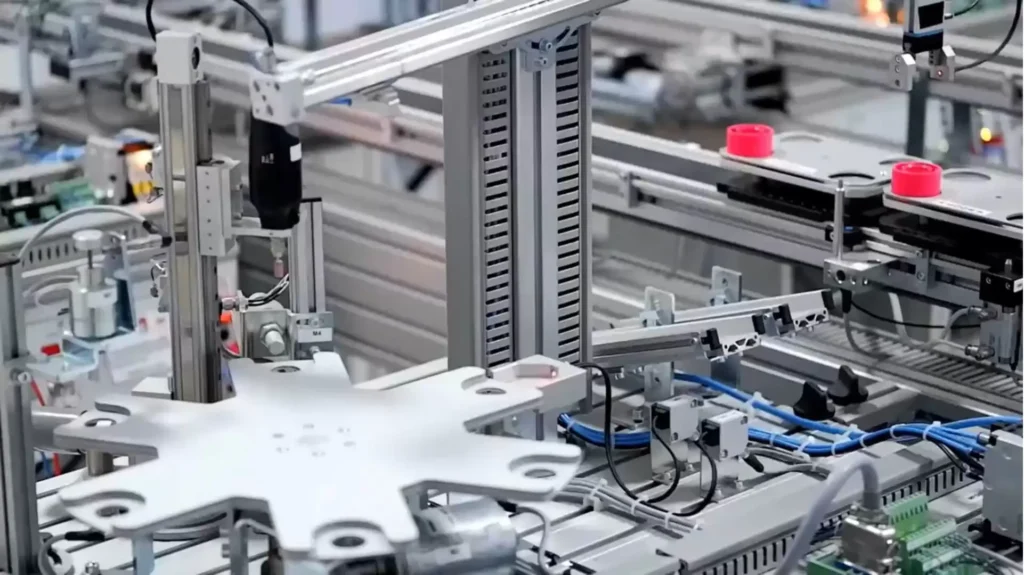

Vision inspection systems (VIS) are machine vision systems that use cameras and image processing software to inspect products for defects. They can be used to inspect products at any stage of the manufacturing process, from raw materials to finished products.

VIS are used in a wide variety of industries, including automotive, electronics, food and beverage, and consumer goods. They are used to inspect a wide variety of products, such as car parts, circuit boards, bottles and cans, and toys and appliances.

VIS offer a number of advantages over traditional inspection methods, including:

- Increased accuracy: VIS can inspect products with a higher degree of accuracy than human inspectors. This is because VIS can be programmed to identify and classify defects that are too difficult or time-consuming for humans to see.

- Reduced costs: VIS can help to reduce the costs associated with quality control by eliminating the need for manual inspection. This can free up workers to perform other tasks or to focus on quality control in other areas.

- Increased productivity: VIS can help to increase productivity by reducing the time required to inspect products. This is because VIS can inspect products very quickly and accurately.

- Improved quality: VIS can help to improve the quality of products by identifying and eliminating defects early in the manufacturing process. This can help to reduce the number of defective products that reach customers.

Here are some examples of how VIS are used in industry:

- In the automotive industry, VIS are used to inspect car parts for defects such as cracks, scratches, and misaligned parts.

- In the electronics industry, VIS are used to inspect circuit boards for defects such as missing components, solder bridges, and cracks.

- In the food and beverage industry, VIS are used to inspect bottles and cans for defects such as cracks, dents, and foreign objects.

- In the consumer goods industry, VIS are used to inspect toys and appliances for defects such as missing parts, cracks, and scratches.

VIS are an essential tool for businesses that need to produce high-quality products. They can help to improve accuracy, reduce costs, increase productivity, and improve quality.

Here are some of the latest trends in vision inspection systems:

- The use of deep learning: Deep learning is a type of machine learning that uses artificial neural networks to learn from data. Deep learning is being used to develop vision inspection systems that can identify and classify defects with even greater accuracy than traditional systems.

- The use of 3D imaging: 3D imaging is being used to develop vision inspection systems that can inspect products from all angles. This can help to identify defects that would be difficult or impossible to see with traditional 2D imaging.

- The use of edge computing: Edge computing is a type of computing architecture in which data is processed and analyzed at the point of collection. This can help to reduce latency and improve performance in vision inspection systems.

Vision inspection systems are a rapidly evolving field. New technologies and applications are being developed all the time. Vision inspection systems are playing an increasingly important role in helping businesses to produce high-quality products.