Nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts in a variety of industries, including automotive, aerospace, construction, and manufacturing. These machines can help to improve efficiency, accuracy, and safety in the workplace.

There are two main types of nut and bolt tightening automation machines: hydraulic and electric. Hydraulic machines use hydraulic pressure to tighten and loosen nuts and bolts, while electric machines use electric motors.

Hydraulic machines are typically more powerful and can be used to tighten and loosen larger nuts and bolts. Electric machines are more portable and can be used in a wider range of applications.

Both hydraulic and electric nut and bolt tightening automation machines can be programmed to tighten and loosen nuts and bolts to a specific torque. This helps to ensure that the nuts and bolts are tightened correctly and that the joint is secure.

Nut and bolt tightening automation machines can also be equipped with sensors to detect if a nut or bolt is loose or if there is too much torque being applied. This helps to prevent accidents and injuries.

Here are some of the benefits of using nut and bolt tightening automation machines:

- Increased efficiency: Nut and bolt tightening automation machines can tighten and loosen nuts and bolts much faster than manual methods. This can lead to significant time savings on production lines and in other applications.

- Improved accuracy: Nut and bolt tightening automation machines can be programmed to tighten and loosen nuts and bolts to a specific torque. This helps to ensure that the nuts and bolts are tightened correctly and that the joint is secure.

- Reduced injuries: Nut and bolt tightening automation machines can help to reduce the risk of injuries to workers. This is because workers are not required to manually tighten and loosen nuts and bolts, which can be a physically demanding task.

Nut and bolt tightening automation machines are an important tool for many industries. They can help to improve efficiency, accuracy, and safety in the workplace.

Operation in Nut and Bolt Tightening Automation Machines

The operation of nut and bolt tightening automation machines can be broken down into the following steps:

- Loading the machine: The first step is to load the machine with the nuts and bolts that need to be tightened or loosened. This can be done manually or using an automated feeder.

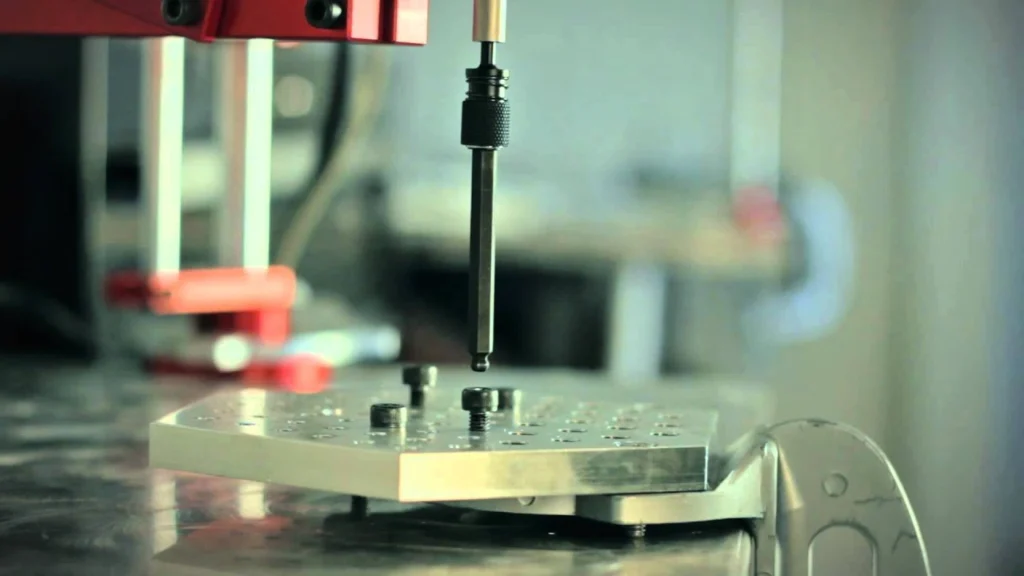

- Positioning the nut or bolt: Once the nut or bolt is loaded into the machine, it needs to be positioned correctly. This can be done using a variety of methods, such as pneumatic actuators, servo motors, or vision systems.

- Tightening or loosening the nut or bolt: Once the nut or bolt is positioned correctly, the machine can begin to tighten or loosen it. This is done using a variety of methods, such as hydraulic actuators, electric motors, or ultrasonic welding.

- Unloading the machine: Once the nut or bolt has been tightened or loosened to the correct specifications, it can be unloaded from the machine. This can be done manually or using an automated conveyor system.

The specific steps involved in operating a nut and bolt tightening automation machine will vary depending on the type of machine and the specific application. However, the general steps outlined above are common to most machines.

Here are some additional details about each step:

Loading the machine: Manual loading can be done by placing the nuts and bolts into the machine’s feed hopper or onto a conveyor belt. Automated feeders can use a variety of methods to load the nuts and bolts into the machine, such as vacuum suction or robotic arms.

Positioning the nut or bolt: Pneumatic actuators and servo motors can be used to position the nut or bolt using a variety of mechanisms, such as clamps, grippers, and spindles. Vision systems can be used to identify the nut or bolt and then guide the positioning mechanism to the correct location.

Tightening or loosening the nut or bolt: Hydraulic actuators are typically used for heavy-duty applications where high torque is required. Electric motors are more common for light-duty applications. Ultrasonic welding is used for plastic nuts and bolts.

Unloading the machine: Manual unloading can be done by removing the nuts and bolts from the machine’s output hopper or conveyor belt. Automated conveyor systems can transport the nuts and bolts to a separate location for further processing or packaging.

Nut and bolt tightening automation machines can be programmed to perform a variety of operations, such as:

- Tightening nuts and bolts to a specific torque

- Loosening nuts and bolts to a specific torque

- Tightening or loosening nuts and bolts in a specific sequence

- Tightening or loosening nuts and bolts to a specific pattern

These machines can also be equipped with sensors to monitor the tightening or loosening process and to ensure that the nuts and bolts are tightened or loosened to the correct specifications.

Nut and bolt tightening automation machines are a valuable tool for many industries, as they can help to improve efficiency, accuracy, and safety in the workplace.tunesharemore_vert

Application Areas

Nut and bolt tightening automation machines are used in a wide variety of industries, including:

- Automotive: Nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on cars, trucks, buses, and other vehicles. This includes applications such as engine assembly, chassis assembly, and body assembly.

- Aerospace: Nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on aircraft and spacecraft. This includes applications such as wing assembly, fuselage assembly, and engine assembly.

- Construction: Nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on bridges, buildings, and other structures. This includes applications such as steel erection, concrete formwork, and bridge deck construction.

- Manufacturing: Nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on a wide variety of products, including appliances, electronics, and machinery. This includes applications such as product assembly, equipment maintenance, and quality control.

In addition to these specific industries, nut and bolt tightening automation machines are also used in a variety of other applications, such as:

- Oil and gas: Nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on oil rigs, pipelines, and other oil and gas equipment.

- Power generation: Nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on power plants, wind turbines, and other power generation equipment.

- Mining: Nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on mining equipment, such as excavators, bulldozers, and dump trucks.

- Railroad: Nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on locomotives, railcars, and other railroad equipment.

Overall, nut and bolt tightening automation machines are a versatile tool that can be used in a wide variety of industries and applications.

Here are some specific examples of how nut and bolt tightening automation machines are used in different industries:

- In the automotive industry, nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on car engines, transmissions, and other components. They are also used to tighten and loosen nuts and bolts on car bodies and frames.

- In the aerospace industry, nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on aircraft engines, wings, and fuselages. They are also used to tighten and loosen nuts and bolts on spacecraft and satellites.

- In the construction industry, nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on bridges, buildings, and other structures. They are also used to tighten and loosen nuts and bolts on cranes, bulldozers, and other construction equipment.

- In the manufacturing industry, nut and bolt tightening automation machines are used to tighten and loosen nuts and bolts on a wide variety of products, such as appliances, electronics, and machinery. They are also used to tighten and loosen nuts and bolts on production lines and assembly lines.

Nut and bolt tightening automation machines can help to improve efficiency, accuracy, and safety in a wide variety of industries.