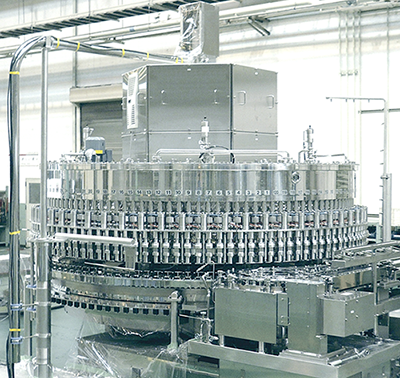

High-speed beverage filling lines are used to fill and package beverages of all types, including carbonated soft drinks, beer, wine, spirits, water, and juice. These lines are typically capable of filling hundreds or even thousands of bottles per minute.

High-speed beverage filling lines typically consist of the following components:

- Depalletizer: The depalletizer removes the empty bottles from the pallets and loads them onto the conveyor belt.

- Rinser: The rinser rinses the empty bottles with sterile water to ensure that they are clean and free of contaminants.

- Filler: The filler fills the bottles with the beverage product.

- Capper: The capper caps and seals the filled bottles with a variety of closures, such as screw caps, crown caps, or aluminum foil lids.

- Labeler: The labeler applies labels to the filled bottles.

- Case packer: The case packer packs the filled bottles into cases.

- Palletizer: The palletizer palletizes the cases onto pallets for shipping.

High-speed beverage filling lines are typically made of stainless steel, which is a durable and sanitary material. The lines are also equipped with a variety of sensors and safety devices to ensure that the beverage products are of the highest quality and that the lines are operated safely.

Here are some of the benefits of using high-speed beverage filling lines:

- Increased productivity: High-speed beverage filling lines can fill and package hundreds or even thousands of bottles per minute, which can significantly increase productivity for beverage manufacturers.

- Improved efficiency: High-speed beverage filling lines automate the entire bottling process, which can improve efficiency and reduce labor costs.

- Reduced waste: High-speed beverage filling lines are very precise and accurate, which can help to reduce waste.

- Improved quality: High-speed beverage filling lines are designed to fill and package beverage products in a sterile environment, which can help to improve the quality of the finished products.

High-speed beverage filling lines are an essential piece of equipment for beverage manufacturers. By automating the bottling process and increasing productivity, high-speed beverage filling lines can help companies to reduce costs and produce large quantities of high-quality beverage products efficiently.

Here are some of the latest trends in high-speed beverage filling line technology:

- The use of artificial intelligence (AI): AI is being used to develop high-speed beverage filling lines that can learn and adapt to changing conditions. This is making high-speed beverage filling lines more flexible and versatile, and better suited for a variety of applications.

- The use of robotics: Robotics is being used to automate tasks in the filling process, such as loading and unloading machines and packing products. This can help to reduce labor costs and improve safety.

- The use of the Internet of Things (IoT): IoT devices can be used to collect data from high-speed beverage filling lines and send it to the cloud for analysis. This data can be used to monitor the performance of the lines and identify potential problems early on.

High-speed beverage filling line technology is constantly evolving. New technologies and applications are being developed all the time. This is helping beverage manufacturers to improve the efficiency, quality, and safety of their operations.

The Use of Artificial Intelligence (AI) in High-Speed Beverage Filling Lines

Artificial intelligence (AI) is being used in high-speed beverage filling lines to improve efficiency, quality, and safety. AI can be used to automate tasks, monitor the filling process, and predict potential problems.

Here are some specific examples of how AI is being used in high-speed beverage filling lines:

- Automated quality control: AI-powered cameras can be used to inspect bottles for defects, such as cracks, scratches, and incorrect fill levels. This can help to reduce the number of defective bottles that reach consumers.

- Predictive maintenance: AI can be used to analyze data from the filling line to predict when maintenance is needed. This can help to prevent unplanned downtime and keep the filling line running smoothly.

- Process optimization: AI can be used to optimize the filling process to improve efficiency and reduce waste. For example, AI can be used to adjust the fill volume and capping torque to ensure that each bottle is filled accurately and consistently.

AI is still a relatively new technology in the beverage industry, but it has the potential to revolutionize the way that beverages are filled. AI can help to improve the efficiency, quality, and safety of high-speed beverage filling lines, while also reducing costs.

Here are some specific examples of companies that are using AI in high-speed beverage filling lines:

- Krones: Krones is a leading supplier of beverage filling systems. Krones offers a variety of AI-powered solutions for beverage filling, including automated quality control, predictive maintenance, and process optimization.

- Sidel: Sidel is another leading supplier of beverage filling systems. Sidel offers a variety of AI-powered solutions for beverage filling, including automated quality control, predictive maintenance, and process optimization.

- GEA: GEA is a leading supplier of food and beverage processing equipment. GEA offers a variety of AI-powered solutions for beverage filling, including automated quality control, predictive maintenance, and process optimization.

The use of AI in high-speed beverage filling lines is expected to grow in the coming years. As AI technology continues to develop, we can expect to see even more innovative and sophisticated AI-powered solutions for the beverage industry.tunesharemore_vert

The use of robotics in High-Speed Beverage Filling Lines

Robotics is playing an increasingly important role in high-speed beverage filling lines. Robots can be used to perform a variety of tasks, including:

- Pallet loading and unloading: Robots can be used to load and unload pallets of empty and full beverage bottles. This can help to improve efficiency and reduce labor costs.

- Bottle handling: Robots can be used to pick and place bottles at various stages of the filling process. For example, robots can be used to pick bottles from pallets, place them on the filling line, and then remove them from the filling line and place them on pallets or in cases.

- Quality control: Robots can be used to perform quality control tasks, such as inspecting bottles for defects and checking fill levels.

- Packaging: Robots can be used to pack bottles into cases or cartons.

The use of robotics in high-speed beverage filling lines offers a number of benefits, including:

- Increased productivity: Robots can perform tasks more quickly and efficiently than humans, which can lead to increased productivity.

- Reduced labor costs: Robots can help to reduce labor costs, especially for repetitive tasks.

- Improved quality: Robots can perform tasks with greater precision and accuracy than humans, which can lead to improved product quality.

- Reduced risk of injury: Robots can perform tasks that are dangerous or hazardous for humans, reducing the risk of injury.

- Improved flexibility: Robots can be easily reprogrammed to perform different tasks, which makes them more flexible than human workers.

Here are some specific examples of how robots are being used in high-speed beverage filling lines:

- KUKA: KUKA offers a variety of robotic solutions for beverage filling, including palletizing, depalletizing, bottle handling, quality control, and packaging.

- ABB: ABB also offers a variety of robotic solutions for beverage filling, including palletizing, depalletizing, bottle handling, quality control, and packaging.

- FANUC: FANUC is another major supplier of robotic solutions for beverage filling. FANUC robots can be used to perform a variety of tasks, including palletizing, depalletizing, bottle handling, quality control, and packaging.

The use of robotics in high-speed beverage filling lines is expected to grow in the coming years. As robotic technology continues to develop, we can expect to see even more innovative and sophisticated robotic solutions for the beverage industry.

Here are some additional benefits of using robots in high-speed beverage filling lines:

- Improved food safety: Robots can help to improve food safety by reducing the risk of human contamination.

- Reduced environmental impact: Robots can help to reduce the environmental impact of beverage filling operations by reducing energy consumption and waste.

- Increased competitiveness: The use of robots can help beverage companies to be more competitive by improving efficiency and reducing costs.

Overall, the use of robotics in high-speed beverage filling lines offers a number of significant benefits for beverage companies. Robots can help to improve productivity, quality, safety, and competitiveness.

The use of the Internet of Things in High-Speed Filling Lines

The Internet of Things (IoT) is being used in high-speed beverage filling lines to collect data from the filling line and to control the filling process. This data can be used to optimize the filling process, improve quality, and reduce waste.

Here are some specific examples of how IoT is being used in high-speed beverage filling lines:

- Monitoring the filling process: IoT sensors can be used to monitor the filling process and to collect data on temperature, pressure, flow rate, and fill volume. This data can be used to ensure that the filling process is running smoothly and that the bottles are being filled accurately and consistently.

- Predicting potential problems: IoT sensors can be used to predict potential problems with the filling process. For example, sensors can be used to detect changes in temperature or pressure that could indicate a problem with the filling machine. This information can be used to prevent problems before they occur.

- Optimizing the filling process: IoT data can be used to optimize the filling process and improve efficiency. For example, IoT data can be used to adjust the fill volume and capping torque to ensure that each bottle is filled accurately and consistently.

- Improving quality: IoT data can be used to improve the quality of the finished product. For example, IoT data can be used to identify and reject bottles with defects. This can help to reduce the number of defective bottles that reach consumers.

The use of IoT in high-speed beverage filling lines is still in its early stages of development, but it has the potential to revolutionize the way that beverages are filled. IoT can help to improve the efficiency, quality, and safety of high-speed beverage filling lines, while also reducing costs.

Here are some specific examples of companies that are using IoT in high-speed beverage filling lines:

- Krones: Krones is a leading supplier of beverage filling systems. Krones offers a variety of IoT-powered solutions for beverage filling, including monitoring the filling process, predicting potential problems, optimizing the filling process, and improving quality.

- Sidel: Sidel is another leading supplier of beverage filling systems. Sidel offers a variety of IoT-powered solutions for beverage filling, including monitoring the filling process, predicting potential problems, optimizing the filling process, and improving quality.

- GEA: GEA is a leading supplier of food and beverage processing equipment. GEA offers a variety of IoT-powered solutions for beverage filling, including monitoring the filling process, predicting potential problems, optimizing the filling process, and improving quality.

The use of IoT in high-speed beverage filling lines is expected to grow in the coming years. As IoT technology continues to develop, we can expect to see even more innovative and sophisticated IoT-powered solutions for the beverage industry.