An automated commercial packaging line is a system of machines that automatically packages products for commercial sale. Automated commercial packaging lines are used in a wide range of industries, including food and beverage, pharmaceutical, cosmetics, and consumer goods.

Automated commercial packaging lines typically consist of the following components:

- Product feeder: The product feeder feeds the products onto the conveyor belt.

- Conveyor belt: The conveyor belt transports the products through the packaging line.

- Packaging machine: The packaging machine packages the products in the desired material, such as plastic film, cardboard boxes, or metal cans.

- Labeler: The labeler applies labels to the packaged products.

- Case packer: The case packer packs the packaged products into cases.

- Palletizer: The palletizer stacks the cases onto pallets.

Automated commercial packaging lines are controlled by a computer system, which monitors the progress of the products through the packaging line and ensures that each task is completed correctly. The computer system can also be used to collect data about the packaging process, which can be used to improve efficiency and quality.

Automated commercial packaging lines offer a number of benefits for businesses, including:

- Increased productivity: Automated packaging lines can help to increase productivity by automating repetitive and time-consuming tasks.

- Improved quality: Automated packaging lines can help to improve quality by reducing the risk of human error.

- Reduced costs: Automated packaging lines can help to reduce costs by reducing labor costs and by improving efficiency.

- Improved safety: Automated packaging lines can help to improve safety by reducing the risk of workplace accidents.

Automated commercial packaging lines are a key part of modern manufacturing, and they are playing an increasingly important role in helping businesses to improve their efficiency, productivity, quality, and safety.

Here are some examples of how automated commercial packaging lines are being used today:

- Food and beverage: Automated packaging lines are used to package food and beverage products, such as bread, snacks, drinks, and frozen foods.

- Pharmaceutical: Automated packaging lines are used to package pharmaceutical products, such as drugs, medical devices, and over-the-counter medications.

- Cosmetics: Automated packaging lines are used to package cosmetics products, such as makeup, skincare products, and hair care products.

- Consumer goods: Automated packaging lines are used to package consumer goods, such as toys, electronics, and household products.

Automated commercial packaging lines are a rapidly growing field, and we can expect to see even more innovative and sophisticated automated packaging lines in the future. As automation technology continues to develop, we can expect to see automated packaging lines that are able to package a wider range of products with greater precision and accuracy.

Automated Commercial Packaging Line Applications

Automated commercial packaging lines are used in a wide variety of industries to package a wide variety of products. Some common applications include:

- Food and beverage: Automated packaging lines are used to package food and beverage products such as bottled water, canned goods, snacks, and frozen foods.

- Pharmaceuticals: Automated packaging lines are used to package pharmaceutical products such as prescription drugs, over-the-counter medications, and medical supplies.

- Consumer goods: Automated packaging lines are used to package consumer goods such as personal care products, household goods, and electronics.

- E-commerce: Automated packaging lines are used to package products for e-commerce fulfillment.

Specific examples of automated commercial packaging line applications include:

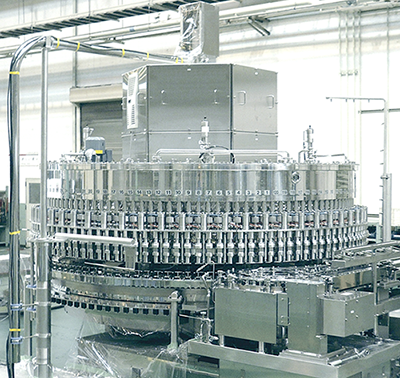

- Bottling lines: Automated bottling lines are used to fill and cap bottles of water, soda, beer, and other beverages.

- Canned goods lines: Automated canned goods lines are used to fill and seal cans of food, beverages, and other products.

- Cartoning lines: Automated cartoning lines are used to place products in cartons or boxes.

- Case packing lines: Automated case packing lines are used to pack cartons or boxes into cases.

- Palletizing lines: Automated palletizing lines are used to stack cases onto pallets.

Automated commercial packaging lines can be customized to meet the specific needs of each industry and product. For example, automated bottling lines for beverages may include different types of filling and capping machines depending on the type of beverage being packaged. Automated cartoning lines for pharmaceuticals may include different types of cartoning machines depending on the size and shape of the product being packaged.

Automated commercial packaging lines offer a number of benefits, including:

- Increased productivity: Automated packaging lines can run faster and more efficiently than manual packaging operations, resulting in increased productivity.

- Reduced labor costs: Automated packaging lines can reduce the need for manual labor, resulting in reduced labor costs.

- Improved product quality: Automated packaging lines can help to improve product quality by reducing the risk of human error.

- Increased safety: Automated packaging lines can help to improve safety by reducing the need for workers to interact with moving machinery.

Overall, automated commercial packaging lines can help businesses to improve their efficiency, productivity, and profitability.

Automated Food and Beverage Packaging Automation

Automated commercial packaging lines are widely used in the food and beverage industry to package a wide variety of products, including:

- Bottled water

- Canned goods

- Snacks

- Frozen foods

- Dairy products

- Meat and poultry

- Bakery products

- Confectionery

Automated packaging lines offer a number of benefits to the food and beverage industry, including:

- Increased productivity: Automated packaging lines can run faster and more efficiently than manual packaging operations, resulting in increased productivity.

- Reduced labor costs: Automated packaging lines can reduce the need for manual labor, resulting in reduced labor costs.

- Improved product quality: Automated packaging lines can help to improve product quality by reducing the risk of human error.

- Increased safety: Automated packaging lines can help to improve safety by reducing the need for workers to interact with moving machinery.

- Increased food safety: Automated packaging lines can help to improve food safety by reducing the risk of contamination.

Here are some specific examples of automated commercial packaging line applications in the food and beverage industry:

- Bottling lines: Automated bottling lines are used to fill and cap bottles of water, soda, beer, and other beverages. These lines typically include a number of machines, such as bottle washers, fillers, cappers, and labelers.

- Canned goods lines: Automated canned goods lines are used to fill and seal cans of food, beverages, and other products. These lines typically include a number of machines, such as can washers, fillers, seamers, and labelers.

- Cartoning lines: Automated cartoning lines are used to place products in cartons or boxes. These lines typically include a number of machines, such as carton erectors, product loaders, carton closers, and labelers.

- Case packing lines: Automated case packing lines are used to pack cartons or boxes into cases. These lines typically include a number of machines, such as case erectors, carton loaders, case closers, and strappers.

- Palletizing lines: Automated palletizing lines are used to stack cases onto pallets. These lines typically include a number of machines, such as pallet dispensers, case loaders, and pallet wrappers.

Automated commercial packaging lines can be customized to meet the specific needs of each food and beverage manufacturer. For example, an automated bottling line for water may be different from an automated bottling line for beer. Automated cartoning lines for snacks may be different from automated cartoning lines for dairy products.

Overall, automated commercial packaging lines play an important role in the food and beverage industry by helping manufacturers to improve their efficiency, productivity, profitability, and food safety.

Pharmaceuticals Packaging

Automated packaging lines offer a number of benefits to the pharmaceutical industry, including:

- Increased productivity: Automated packaging lines can run faster and more efficiently than manual packaging operations, resulting in increased productivity.

- Reduced labor costs: Automated packaging lines can reduce the need for manual labor, resulting in reduced labor costs.

- Improved product quality: Automated packaging lines can help to improve product quality by reducing the risk of human error.

- Increased safety: Automated packaging lines can help to improve safety by reducing the need for workers to interact with moving machinery.

- Increased product integrity: Automated packaging lines can help to ensure the integrity of pharmaceutical products by reducing the risk of contamination.

Here are some specific examples of automated commercial packaging line applications in the pharmaceutical industry:

- Blister packaging lines: Automated blister packaging lines are used to package pharmaceutical products in blister packs. These lines typically include a number of machines, such as blister feeders, product loaders, heat sealers, and labelers.

- Vial filling and capping lines: Automated vial filling and capping lines are used to fill and cap vials with pharmaceutical products. These lines typically include a number of machines, such as vial washers, fillers, cappers, and labelers.

- Cartoning lines: Automated cartoning lines are used to place pharmaceutical products in cartons or boxes. These lines typically include a number of machines, such as carton erectors, product loaders, carton closers, and labelers.

- Case packing lines: Automated case packing lines are used to pack cartons or boxes into cases. These lines typically include a number of machines, such as case erectors, carton loaders, case closers, and strappers.

- Palletizing lines: Automated palletizing lines are used to stack cases onto pallets. These lines typically include a number of machines, such as pallet dispensers, case loaders, and pallet wrappers.

Automated commercial packaging lines can be customized to meet the specific needs of each pharmaceutical manufacturer. For example, an automated blister packaging line for prescription drugs may be different from an automated blister packaging line for over-the-counter medications. Automated cartoning lines for vaccines may be different from automated cartoning lines for biologics.

Overall, automated commercial packaging lines play an important role in the pharmaceutical industry by helping manufacturers to improve their efficiency, productivity, profitability, and product integrity.

Consumer Goods Packaging

Automated packaging lines offer a number of benefits to the consumer goods industry, including:

- Increased productivity: Automated packaging lines can run faster and more efficiently than manual packaging operations, resulting in increased productivity.

- Reduced labor costs: Automated packaging lines can reduce the need for manual labor, resulting in reduced labor costs.

- Improved product quality: Automated packaging lines can help to improve product quality by reducing the risk of human error.

- Increased safety: Automated packaging lines can help to improve safety by reducing the need for workers to interact with moving machinery.

- Reduced packaging waste: Automated packaging lines can help to reduce packaging waste by optimizing the packaging process.

Here are some specific examples of automated commercial packaging line applications in the consumer goods industry:

- Cartoning lines: Automated cartoning lines are used to place consumer goods products in cartons or boxes. These lines typically include a number of machines, such as carton erectors, product loaders, carton closers, and labelers.

- Case packing lines: Automated case packing lines are used to pack cartons or boxes into cases. These lines typically include a number of machines, such as case erectors, carton loaders, case closers, and strappers.

- Palletizing lines: Automated palletizing lines are used to stack cases onto pallets. These lines typically include a number of machines, such as pallet dispensers, case loaders, and pallet wrappers.

- Shrink wrapping lines: Automated shrink wrapping lines are used to shrink wrap consumer goods products in plastic film. These lines typically include a number of machines, such as shrink wrap tunnels and conveyors.

- Skin packing lines: Automated skin packing lines are used to skin pack consumer goods products in plastic film. These lines typically include a number of machines, such as skin packing machines and conveyors.

Automated commercial packaging lines can be customized to meet the specific needs of each consumer goods manufacturer. For example, an automated cartoning line for personal care products may be different from an automated cartoning line for household products. Automated case packing lines for electronics may be different from automated case packing lines for cosmetics.

Overall, automated commercial packaging lines play an important role in the consumer goods industry by helping manufacturers to improve their efficiency, productivity, profitability, and product quality.

Cosmetics Packaging

Automated commercial packaging lines are widely used in the cosmetics industry to package a wide variety of products, including:

- Makeup, such as lipstick, foundation, eyeshadow, and mascara

- Skincare products, such as cleansers, moisturizers, and serums

- Hair care products, such as shampoo, conditioner, and styling products

- Fragrances and deodorants

- Nail polish and other nail care products

- Bath and body products, such as soaps, lotions, and gels

Automated packaging lines offer a number of benefits to the cosmetics industry, including:

- Increased productivity: Automated packaging lines can run faster and more efficiently than manual packaging operations, resulting in increased productivity.

- Reduced labor costs: Automated packaging lines can reduce the need for manual labor, resulting in reduced labor costs.

- Improved product quality: Automated packaging lines can help to improve product quality by reducing the risk of human error and contamination.

- Increased safety: Automated packaging lines can help to improve safety by reducing the need for workers to interact with moving machinery.

- Reduced packaging waste: Automated packaging lines can help to reduce packaging waste by optimizing the packaging process.

Here are some specific examples of automated commercial packaging line applications in the cosmetics industry:

- Filling lines: Automated filling lines are used to fill cosmetic products into bottles, tubes, and other containers. These lines typically include a number of machines, such as fillers, cappers, and labelers.

- Cartoning lines: Automated cartoning lines are used to place cosmetic products in cartons or boxes. These lines typically include a number of machines, such as carton erectors, product loaders, carton closers, and labelers.

- Case packing lines: Automated case packing lines are used to pack cartons or boxes into cases. These lines typically include a number of machines, such as case erectors, carton loaders, case closers, and strappers.

- Palletizing lines: Automated palletizing lines are used to stack cases onto pallets. These lines typically include a number of machines, such as pallet dispensers, case loaders, and pallet wrappers.

Automated commercial packaging lines can be customized to meet the specific needs of each cosmetics manufacturer. For example, an automated filling line for lipstick may be different from an automated filling line for foundation. Automated cartoning lines for skincare products may be different from automated cartoning lines for hair care products.

Overall, automated commercial packaging lines play an important role in the cosmetics industry by helping manufacturers to improve their efficiency, productivity, profitability, and product quality.

In addition to the above, here are some specific trends in automated commercial packaging lines for cosmetics:

- Increased use of robotics: Robotics is being used more and more in automated packaging lines for cosmetics. Robots can perform a variety of tasks, such as picking and placing products, filling containers, and packing cartons.

- Greater integration: Automated packaging lines for cosmetics are becoming increasingly integrated. This means that the different machines on the line can communicate with each other and work together more efficiently.

- More customization: Automated packaging lines for cosmetics are being customized more and more to meet the specific needs of each manufacturer. This is especially important for manufacturers of niche or luxury cosmetic products.

Overall, the trend is towards more automated, integrated, and customized packaging lines for cosmetics. This is helping manufacturers to improve their efficiency, productivity, profitability, and product quality.